The structure and configuration list

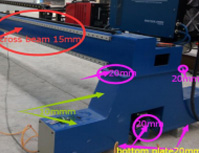

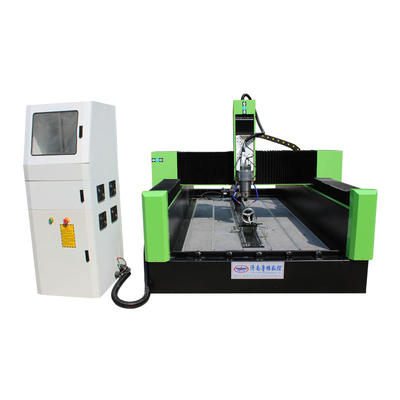

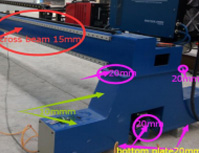

1.Mechanical design heavy fuselage.

2. 2000*6000mm work area.

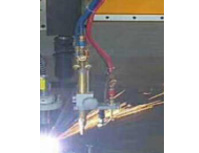

3. China LGK200A plasma source.

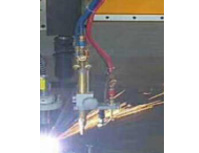

4. Flame cutting system.

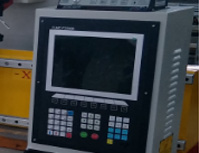

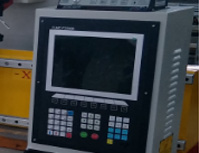

5. SJTU-CNC control system.

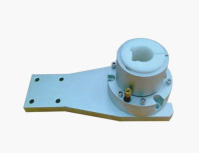

6. Automatic torch height control.

7. fastcam software from Australia.

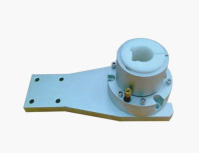

8. High precision Square guide rail.

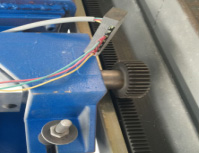

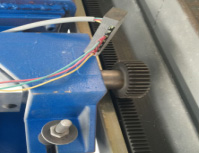

9. Rack and Gear transport system.

10. Stepper motor.

11. Shinbao reducer in Japan.

12. 2GB ready program.

13. Detailed teaching video.

14. Multi-function tool box.

15.All the necessary parts for machine working.

2040 200A plasma cutting machine (high configuration) |

China LGK 200A plasma source | SJTU-CNC control system | Automatic Torch height control | fastcam software |

|

|

|

|

flame cutting | Heavy duty Machine body | Standard export wooden case | 2G processing file |

|

|

|

|

Stepper motor | Anticollision | Rack and gear | Multi-functional tool box |

|

|

|

|

Model | 2560 |

X,Y working area | 2500*6000mm |

Z working area | 150mm |

Lathe bed | Very thick steel structure |

Machine Power | 8.5kw |

Working voltage | 380V/50HZ three phase |

Reposition precision | 0.02mm |

Processing precision | 0.1mm |

Maximum cutting speed | 12000mm/min |

Torch Height control mode | Automatic high sensitive THC |

Plasma power supply | China LGK200A |

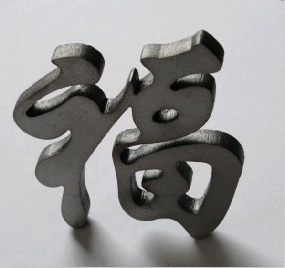

Cutting thickness | Max40mm carbon steel for plasma, max 250mm carbon steel for flame |

Control system | SJTU-CNC control system |

Motors | China brand stepper motor |

Software | fastcam |

Weight | 1600 KGS |

Plasma Air Pressure | Max.0.8Mpa |

Working Temperature | -10°C-60°C. Relative Humidity, 0-95%. |

Flame cutting | 200mm |

1. We have detailed teaching video for customer, like step by step and hand by hand to teach how to use machine and software .etc, so even a freshman will learn machine using faster and easier. While most other factory only have word instructions, we met many customer misunderstand when read the word instruction and lead to operate wrong and damage the machine.

2. The painting: all our machine body have been processed by professional anti-rust treatment. First, we spray 2 times anti-rust paint to ensure that all parts of the machine in a fully protected state, and then spray color. This can effectively prevent the machine rust, resulting in damage to the machine. Other manufacturers do not take anti-rust treatment or only spay 1 time rust paint.

3. Software: our software have self-adjust function. That means, when you put the metal sheets slide, the software will adjust the cutting according to metal sheets direction, so that it will protect the metal sheets and good cutting results. Especially when cut large or expensive metal sheets, this will preventing big loss. While other factory machine does not have this function.

4. Our machine support many languages, like English, Russia, Spanish etc. Then the clients can operate the machine more convenient.

5. When cutting many drawings, our software can automatically sort and achieve best combination, so that the machine can cut all drawings in shortest time.

6. We use super soft shielded cable to ensure that the plasma power supply does not affect the motor during working.

7. Just because our machine all equipped the professional parts, and test more seriously for the whole machine, so our guarantee period it is 2 years, while other factory it is only 1 years.

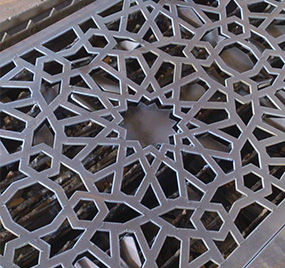

8. We will free provide 2G processing design, in the 2G processing design have thousand beautiful graphic, after you get the machine, you can let the machine do a lot of beautiful work, while no need find the engineer to help you to design.

1. Mature service:

Pre-Sales Service:Inquiry and consulting support, Free making samples support,View our Factory.

After-Sales Service:24 hour technical support by email , telephone or online video ,User friendly English manual for machine using and maintaining, Training how to install the machine and use the machine, Engineers available to service machinery overseas.

2. large machine factory and large quantity producing ability, which can satisfy clients’ large order in short time.

2. large machine factory and large quantity producing ability, which can satisfy clients’ large order in short time.

3. We adopt the strength export wooden case, for shipping. It is efficiently protect the machine in good situation after long term transportation.

4. We have details video can show every part of the operation, so after you getting the machine ,and operate in time, and we can also totally according your requirement to do the video only for your job .