300X300 integrated ceiling twice equipment (small)

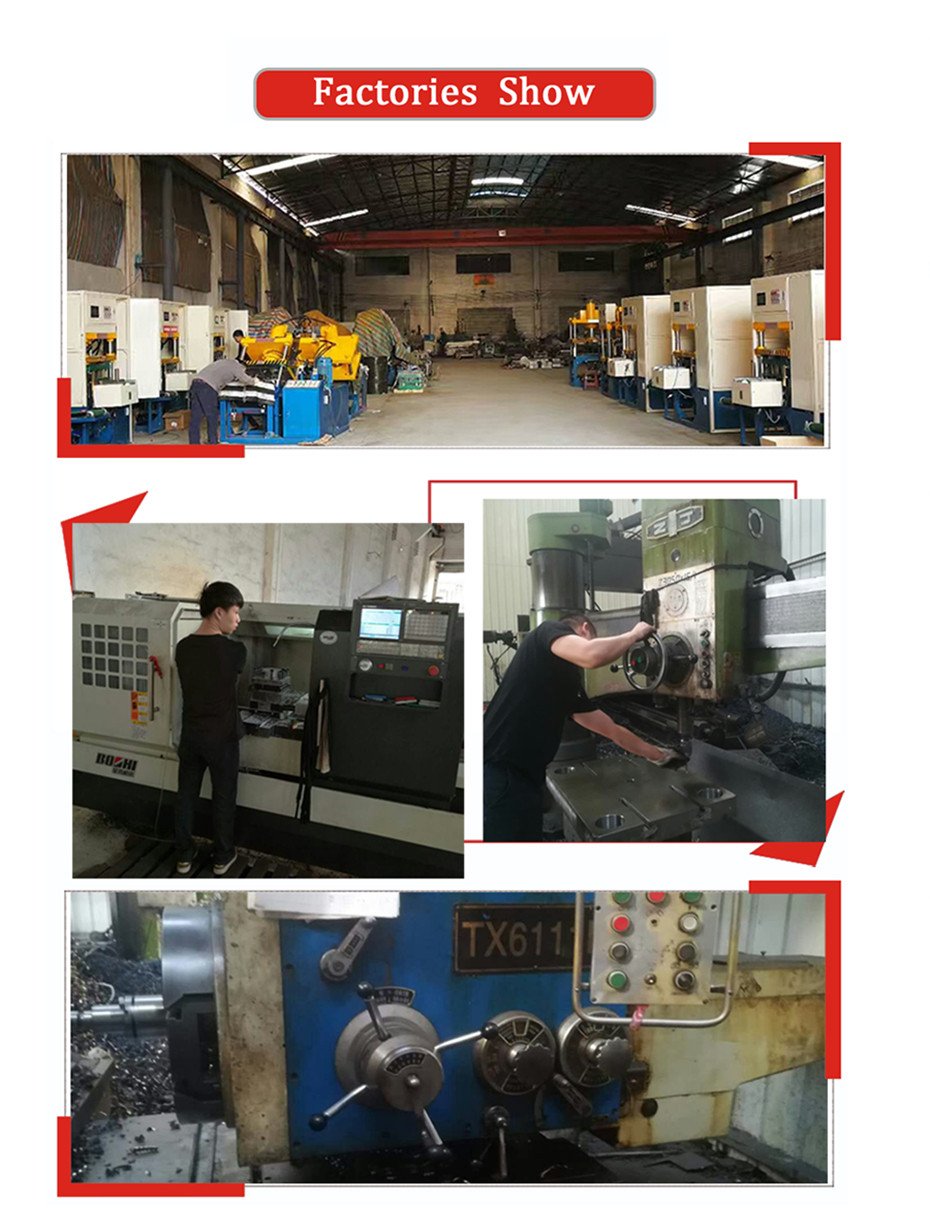

• 17 years of molding equipment industry experience;

• Zero scrap rate;

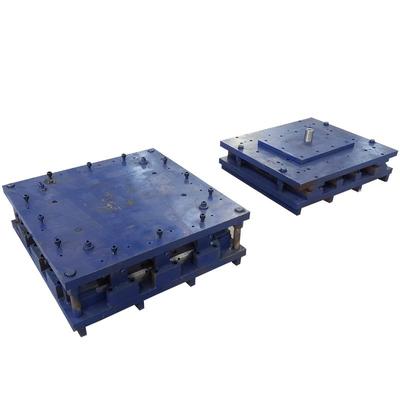

• 2 sets of molds, 2 machines, cutting angle, buckle bit, trademark stamping in the 20T hydraulic press completed, forming, folding and 40T hydraulic press to complete;

• Wiring can be operated without the need for professional training;

• Special technology (die blade), shearing angle, folding step in place;

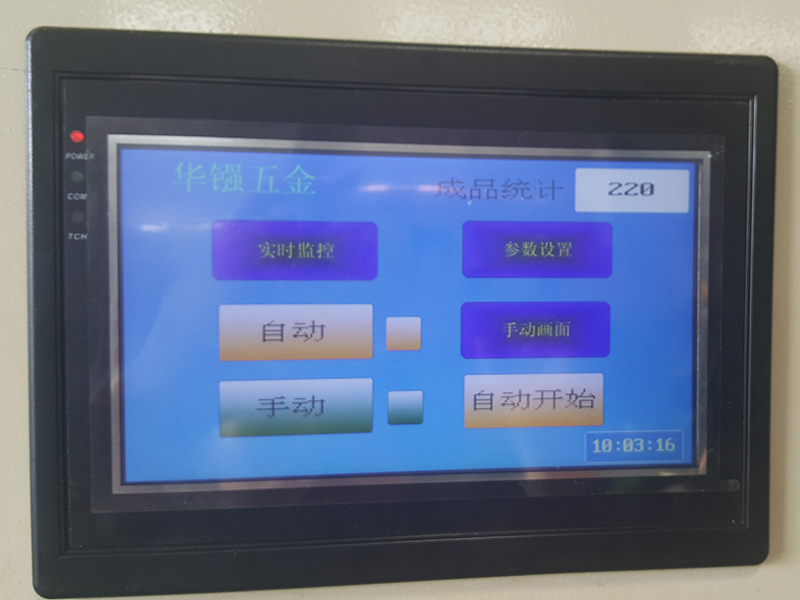

• Jog, automatic control panel, precise operation, easy to operate

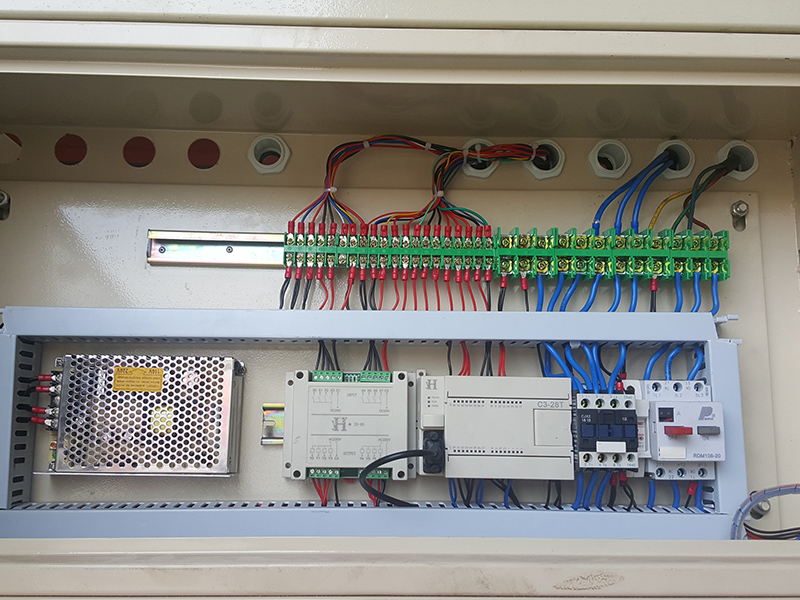

• PLC control, fault at a glance;

• Pure copper core motor, stable performance, fast speed, long life;

• Taiwan solenoid valve, quality assurance;

• Hands control button, easy to operate.

300X300 integrated ceiling twice equipment(small)

300X300 integrated ceiling secondary equipment, mainly for processing 300X300 specifications home ceiling aluminum ceiling machining equipment. A variety of 332 * 332,334 * 334,344 * 344,346 * 346 size and other specifications are available for a general processing of a mold equipment. By 20T hydraulic machine with 40T hydraulic machine plus cutting corner forming mold composition, no need to be equipped with air compressor, then a good line, coupled with hydraulic oil can be put into trial production. First of all, cut angle in the 20T cut corner hydraulic press, put a bag of aluminum material on the right hand side, take a piece of aluminum material in the right hand, into the mold work area, put the aluminum sheet material along the positioning of the mold area, Then left and right hand while pressing the front of the operation button. Equipment into the work mode, less than 2 seconds, aluminum sheets have been folded corners, and then put a bag cut angle material put away. Proceed to the second process, cut the four corners of the sheet material, 40T hydraulic machine flange forming, and then a sheet of molded aluminum buckle into the carton, the operation is completed.

Forming samples

PLC control

wordsVideo visual operation

Parameters

【Motor parameters 】 5.5KW

【 Control System】 PLC integrated circuit

【 Hydraulic original】 Taiwan VTOZ @ solenoid valve

【 Product ivity 】 12 to 15 pieces / min

【Machine weight】 2500KG

【 Hydraulic oil】46 # anti-wear hydraulic oil 200L

Contact

Supplier