Ceramic vacuum disc filter

Porvoo Ceramic vacuum disc filter

Ceramic vacuum disc filter is the world's advanced solid-liquid separation equipment. Its core component ceramic vacuum filter plate is successfully developed by Outokumpu of Finland. The ceramic vacuum filter plate is usually 1-5 microns (the most commonly used is 1.5). - 2.0 micron), such micropores can produce strong capillary action. When the disc filter is working, under the action of the vacuum pump, only the liquid passes through the micropores to become the filtrate, and the solid and gas are blocked on the surface of the filter plate to become the filter cake. , achieving solid-liquid separation.

Ceramic vacuum disc filter can be widely used in the dewatering treatment of sand and gravel aggregates, coal, stone, ceramics, non-ferrous metal mines and other industries, and has a wide range of applications.

main feature • Energy efficient: The processing capacity is large and the energy saving effect is obvious. • Automatic control: Automatic control by PLC program, automatic feeding, automatic cleaning, reduce the labor cost of system operation. • Complete automatic protection: With fault automatic alarm system, faulty screen display function, high and low liquid level alarm display, and automatic elimination or shutdown manual processing. •Strong structure and durability: The structure is reasonable and the work is reliable. The main transmission components adopt maintenance-free design, and the tank body adopts stainless steel structure to ensure its service life can reach more than 10 years. • Filter cake is ultra-dry, reducing transportation costs: The water content of the filtered and dehydrated material is very low, which can greatly reduce the transportation cost and loss. • The environmental protection effect is obvious: Since the filtrate is clear, it can be reused and reduced in emissions, which is in line with the current environmental protection trend of cleaner production.

working principle

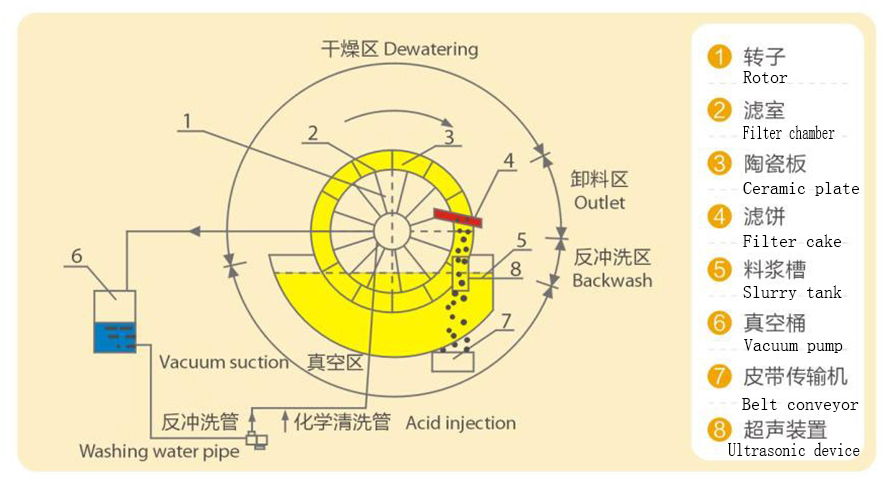

Suction: When the ceramic vacuum disc filter is operated, the vacuum filter plate is rotated under the surface of the slurry immersed in the tank to form a layer of solid particles on the surface of the vacuum filter plate, and the liquid is passed through the vacuum filter plate by the person in charge of distribution. Switch to the vacuum bucket.

Drying: When the filter plate with the accumulated layer leaves the slurry level, a filter cake is formed, and dehydration is continued due to the action of the vacuum to further dry the filter cake.

Unloading: The rotor continues to rotate to the part where the scraper is placed, so that the filter cake is removed and sent to the desired place by the belt conveyor.

Backwashing: After the filter cake is removed, the filter plate is moved to the auto-coupling position to switch to the flushing position opposite to the vacuum flow direction, forming a flushing action from the inside of the filter plate to remove particles trapped in the ceramic micropores. Then re-immersed in the slurry

Deep cleaning: After the filter has been running for a long time, the filter plate can be thoroughly rinsed. The backwashing liquid used can be added with chemicals and ultrasonically oscillated to keep the filter running efficiently.

Technical Parameters

model | PR-12 | PR-16 | PR-20 | PR-24 | PR-30 | PR-32 | PR-36 | PR-45 | PR-48 | PR-60 | PR-80 | PR-100 |

Installed power | 12.15 | 16.25 | 18.75 | 18.75 | 18.75 | 18.75 | 24.55 | 24.55 | 24.55 | 35.9 | 48 | 60.8 |

Operating power | 8.9 | 13 | 16 | 16 | 16 | 16 | 20 | 20 | 20 | 29 | 39 | 48.5 |

quality | 3.5 | 5 | 6 | 7.5 | 9 | 9.5 | 10 | 12 | 12 | 15 | 18 | 20 |

long | 3600 | 4200 | 4700 | 5200 | 5800 | 6100 | 6400 | 7300 | 7300 | 7450 | 8750 | 8150 |

width | 2800 | 2800 | 2800 | 3170 | 3170 | 3170 | 3200 | 3200 | 3200 | 3530 | 3768 | 3850 |

high | 2100 | 2140 | 2140 | 2530 | 2530 | 2530 | 2590 | 2590 | 2590 | 2880 | 2880 | 3200 |

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts