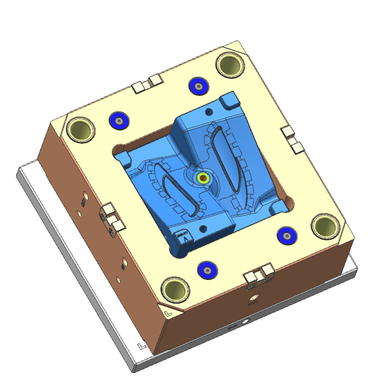

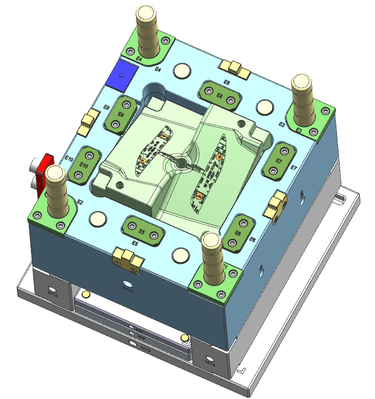

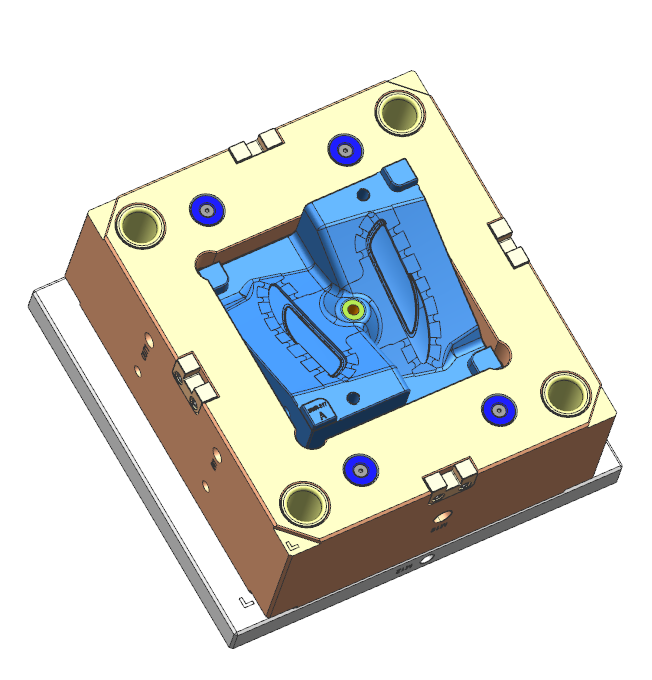

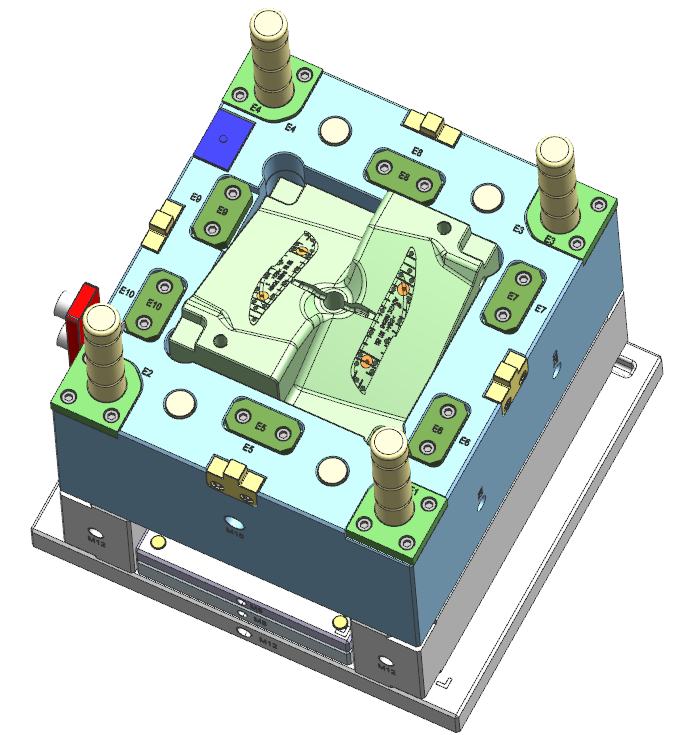

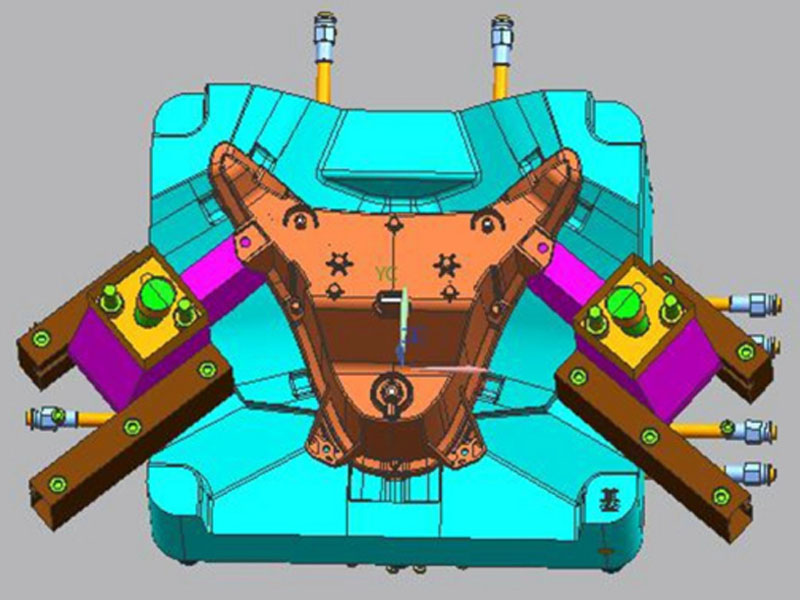

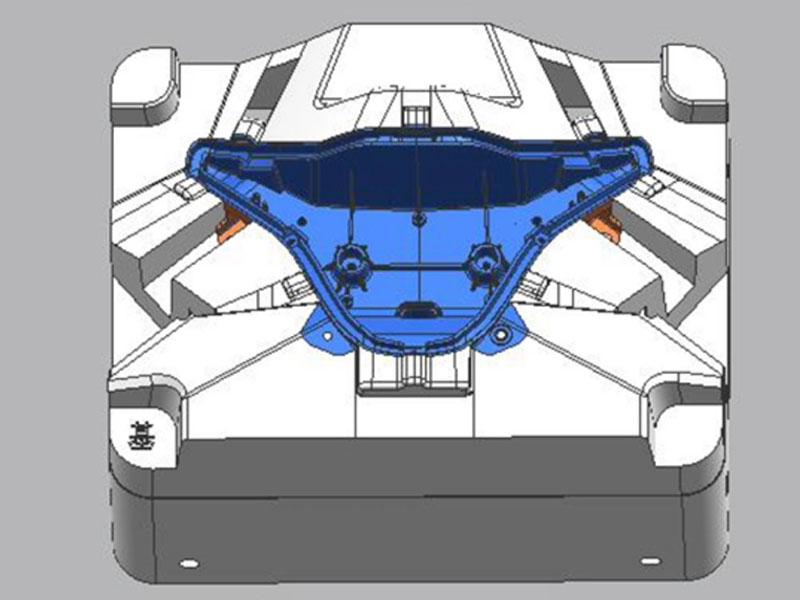

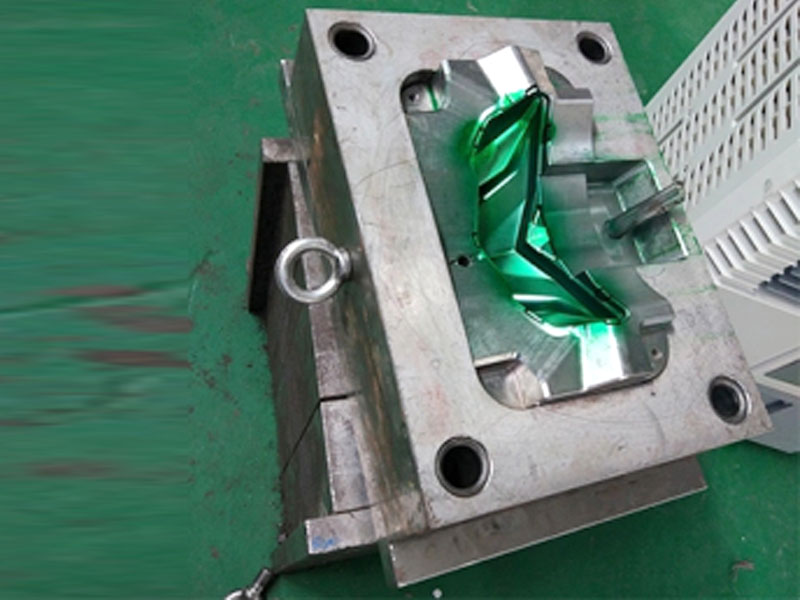

High Precision Emblem Mold

product information

Mold Type | Plastic Injection Mold |

Mold Material | 45#,P20 steel, 718, 2738, H13, NAK80, 2344, 2343, S136 etc . |

Product Material | ABS,PA,PA66+GF,POM,PC,PP,PET,TPE,PVC,HDPE etc |

Mold Base | HASCO, LKM,DME, MISUMI, JIS etc. |

Mold Tooling Equipment | Lathe,Milling,Grinder,Drill,CNC,EDM,Wire cut machine,Punch machine |

Runner Type | Cold Runner or Hot Runner |

Cavity | Single or Multi cavities |

Mold Life | 45#:50,000 to 100,000 shots P20:100,000 to 200,000 shots 718: 200,000 to 300,000 shots S136: 300,000 to 500,000 shots |

Design Software | CAD, CAXA, UG, PROE |

Packing | Wooden packing box for molds and Generally inner packed in opp bags, outside packed in standard export carton with shipping marks. |

Mold plastic two shots injection molding

Packing details: | The mould stared to pack with wooden case after the final sample confirmed,then the mould will be sent to port and waiting for shipping. |

Delivery: | The delivery lead time would be 25-45 working days after payment. |

Company Information

LYX Mold co., Ltd, is a professional design and manufacture of various types of plastic injection molds and plastic products production and processing enterprises, mainly involving automobile lamps, auto parts, motorcycle lamps, medical equipment, communications equipment, sports supplies, household appliances, household goods and other plastic mold and injection molding products production and processing.

FAQ

2. We respect every customer as our friend and we sincerely do business and make friends with them, no matter where they come from.

working

Contact

Supplier