Noise Barrier Roll Forming Machine

Product Descriptions

Noise Barrier Roll Forming Machine uses energy-saving and environmentally friendly materials to produce a water, corrosion and UV resistant noise barrier.

A noise barrier (also called a soundwall, sound berm, sound barrier, or acoustical barrier) is an exterior structure designed to protect inhabitants of sensitive land use areas from noise pollution. Noise barriers are the most effective method of mitigating roadway, railway, and industrial noise sources–other than cessation of the source activity or use of source controls.

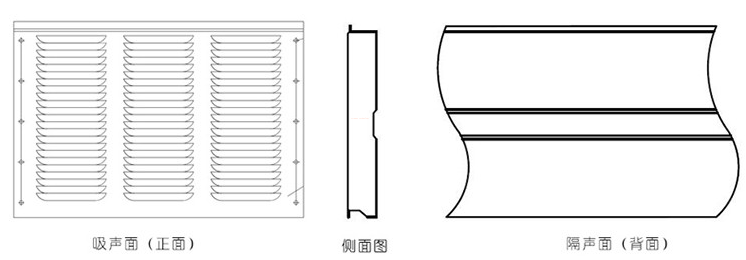

Version to design

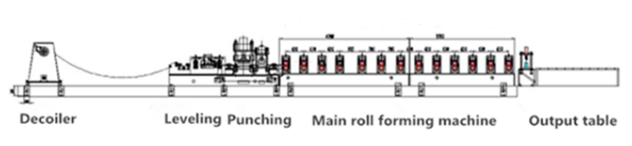

Working Flow

Decoiler - Leveling - Punching - Roll Forming Machine - Hydraulic Cutting - Output table

Product Parameters

Items | Specifications |

Suitable material | PPGI/Aluminium sheet/galvanized sheet/various sheet plates |

Thickness of coil sheet | 0.8-1mm |

Coil width | 825mm |

Effective width | 500mm |

Material of main frame | 350H steel |

Diameter of shaft | 70mm, high grade 45# steel |

Roller | High grade 45# steel, quenched and tempered treatment hard chrome plated 0.05-0.07mm |

Thickness of middle plate | 16mm, 45# steel plate |

Forming station | 18 rows |

Drive type | By chain(1.0 inch), link bearing model 6210 |

Sidewall connection bar | 25mm, zinc plated |

Forming speed | About 10-15m/min |

Control System | PLC |

Material of razor blades | Cr 12, quenching 58-62℃ |

Main Components

5 ton decoiler | 1 set |

Main roll forming machine | 1 set |

Cutting device | 2 sets |

PLC Control box | 1 unit |

Hydraulic station | 1 unit |

Out table | 2 units |

Safety cover | 1 unit(Optional) |

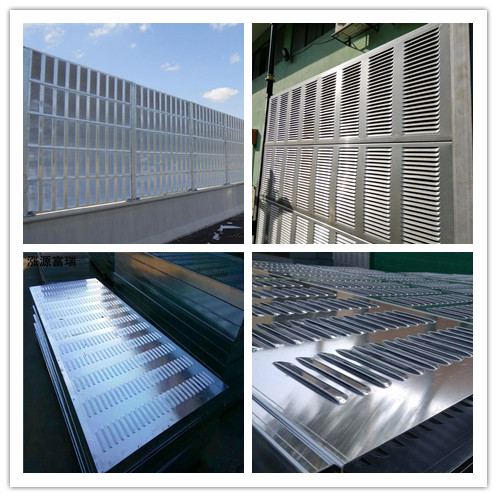

Application Pictures

Sound barrier, mainly used for sound insulation and noise reduction of roads, highways, elevated composite roads and other noise sources. It is divided into a purely sound-reflecting reflective sound barrier, and a composite sound barrier combined with sound absorption and sound insulation. The latter is a more effective sound insulation method. Refers to wall structures placed on the side of railways and highways to mitigate the effects of driving noise on nearby residents. Sound insulation walls are also known as sound barriers. Inserting a facility between the sound source and the receiver causes a significant additional attenuation of the sound wave propagation, thereby attenuating the effects of noise in a certain area of the receiver. Such a facility is called a sound barrier. It is divided into traffic noise barriers, equipment noise attenuation noise barriers, industrial plant noise barriers, roads and highways where most types of sound barriers are used.

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts