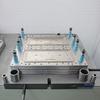

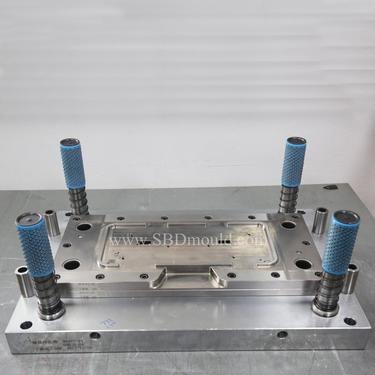

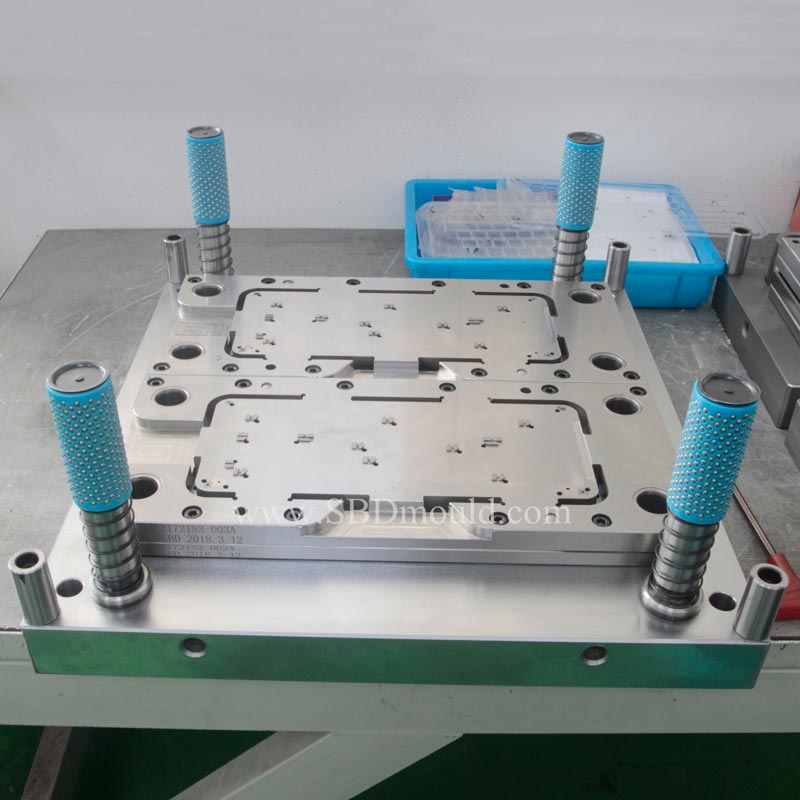

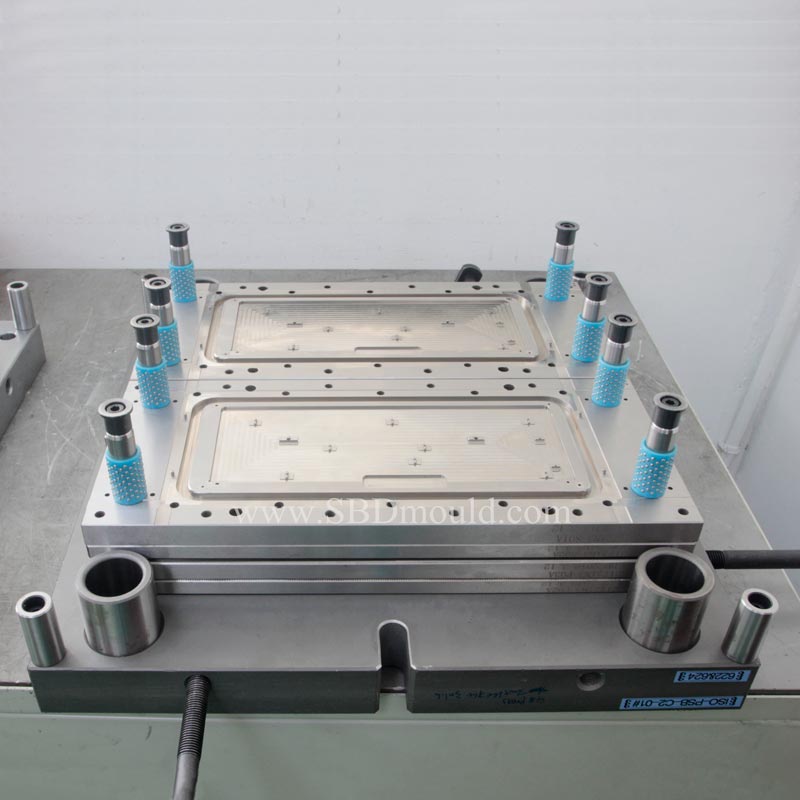

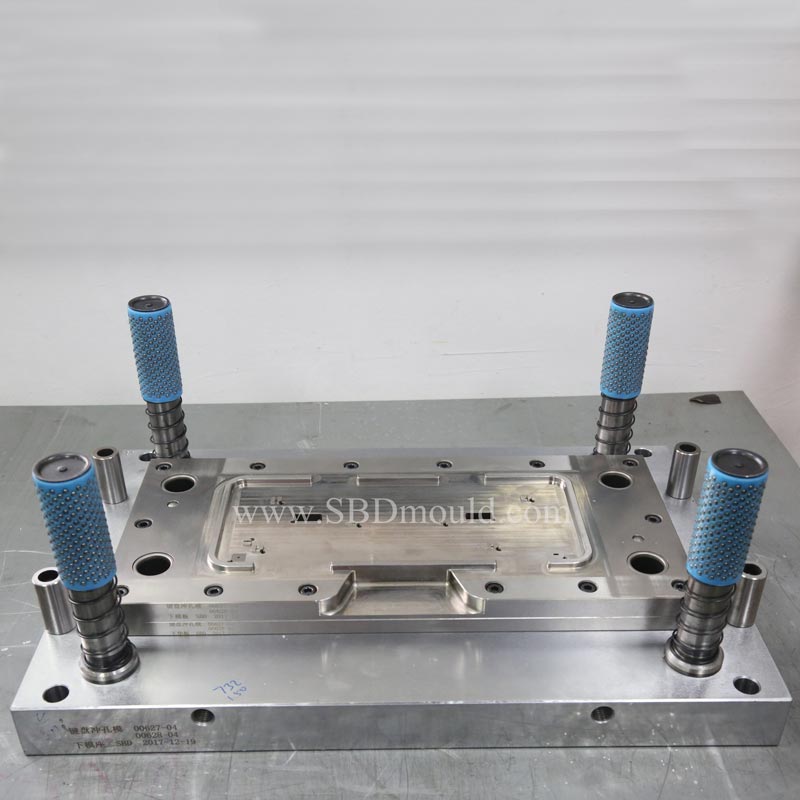

Progressive stamping mould design and making for keyboard

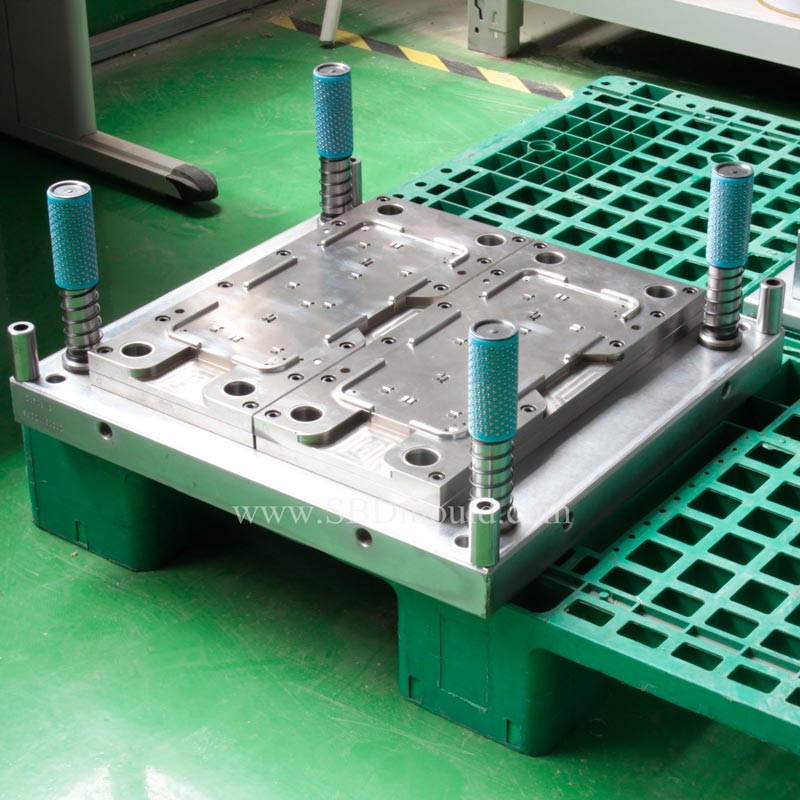

We can design and prodce moulds, custom stamping parts from customers’ drawing design.

We can provide manufacturing & machining service and advice based on customers’ requests in various industries as following:

◆ NEV lithium battery stamping mould (Tooling)

◆ Automotive Connector Mold(Tooling and Mold parts)

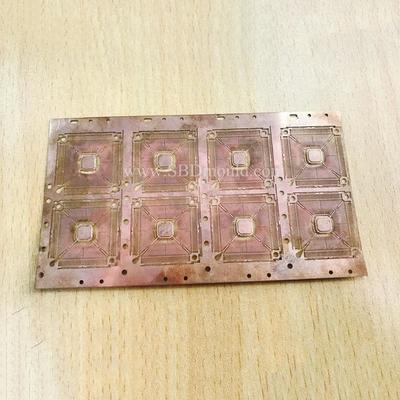

◆ Semiconductor lead frame Mold(Tooling and Mold parts)

◆ Precision Connector Mold(Tooling and Mold parts)

◆ Machining of high precision Mechanical Parts

◆ CNC Precision Machining & Mold Parts Manufacturing

EDM machining mold parts

◆ Copper

◆ Heat Resistant Metals

◆ High Temperature Alloy

◆ Iron

◆ Light Metal

◆ Sheet Metal

◆ Stainless Steel

◆ Steel

◆ Structural Steel

◆ Brass

◆ Bronze

◆ Carbon Steel

◆ Copper

◆ Nickel

◆ Nickel Steel

◆ Nickel Alloys

◆ Stainless Steel

◆ Titanium Alloys

◆ Metal

◆ Non-Metallic

◆ Sand paper

◆ Forming

◆ Bending

◆ Punching holes&Perforated

◆ Fully Sheared

◆ Fine Blanked (strict tolerance with near zero clearance)

◆ Progressive Die (a mould has more than one stamping functions)

◆ Punch press

◆ 0.04 mm to 6 mm

◆ 0.04 mm to 6 mm0±0.01mm

◆ To Customer Specification

◆ Hardness testing

◆ Material testing

◆ Product size testing

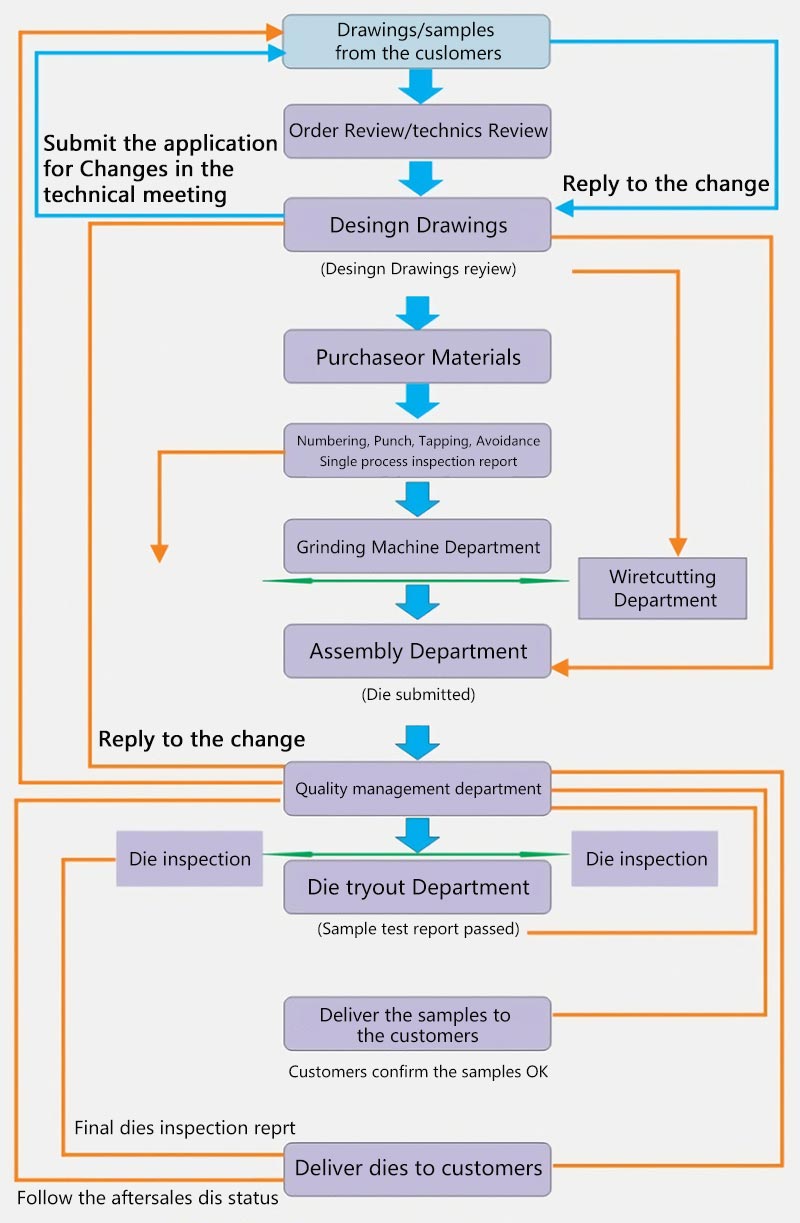

(We would send the sample to our client, and the product is meet the client’s requirement, we would send the mould to our customer)

◆ Commercial Hardware & Equipment

◆ Communication Equipment

◆ Computer and other 3C Equipment

◆ Electronic Terminal connectors& Equipment

◆ Industrial Machinery Equipment

◆ Packaging Machinery

◆ Automation Equipment

◆ New energy vehicle liuminum battery

◆ Initial Graphics Exchange Specification (IGES)

◆ Joint Photographic Experts Group (JPG or JPEG)

◆ Portable Document Format (PDF)

◆ Pro-E or Pro/Engineer (DRW, PRT, XPR)

◆ SolidWorks (SLDPRT, SLDDRW, SLDDRT)

◆ Standard for the Exchange of Product Model Data (STEP)

◆ Tagged Image File Format (TIFF)

◆ Miniature Parts

◆ Thin Gauge parts

◆ Complex small parts

◆ Sand paper

◆ Intricate parts

◆ Small Parts

Contact

Supplier