SJIII-K100 Capsule injection machine

Capsule Injection Machine

Capsule Injection Machine|Product specification|Product Features

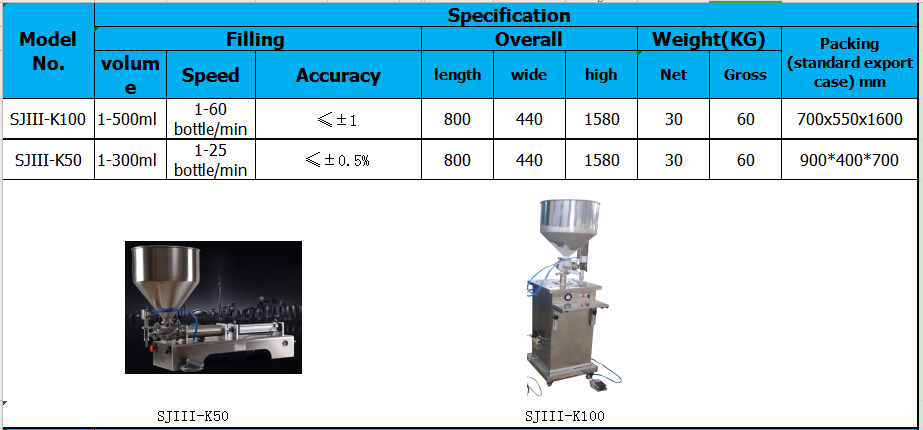

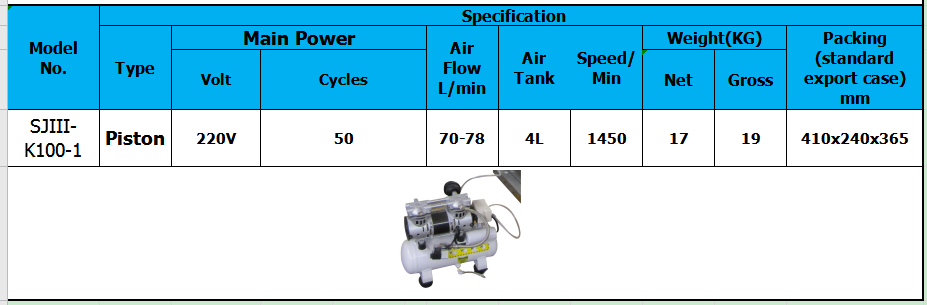

Product specification:

The filling machine is a product of hommy that is transformed and innovated with reference to foreign advanced filling machine technology. Its structure is simpler and more reasonable, with high accuracy and easier operation. Ideal equipment for filling high liquids.

Product Features:

Besides, top qualified engineers, skillful technologists and knowledgeable personal contribute a lot to the company development.

1. The filling machine for filling high-concentration fluids uses the principle of a piston driven by a cylinder to extract and eject high-concentration materials, and control the stroke of the cylinder with a reed switch to adjust the filling volume. The machine can work without electricity, it is safer, and its humanized design is more in line with the requirements of modern enterprises.

2. Steel: The body is made of stainless steel, and the material contact parts are sanitary 304 stainless steel, which meets GMP and QS safety requirements.

3. Filling dose: The filling volume and filling speed can be adjusted arbitrarily, and the filling accuracy is high.

4. The filling bulkhead adopts anti-drip, anti-drawing filling device and lifting filling device.

5. With stirring, it is more suitable for products with high viscosity and poor fluidity.

6. Since the parts of the machine in contact with materials are all made of stainless steel, it has anti-embroidery and corrosion resistance.

7. This machine is completely controlled by compressed air, no power supply is needed, and it is especially used in explosion-proof environments with high safety;

8. Due to the pneumatic control and mechanical positioning, the filling accuracy is high, which is controlled within 0.5 ‰;

9. The operation is simple and easy to use; the failure rate is low.

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Air-Compressors & Parts