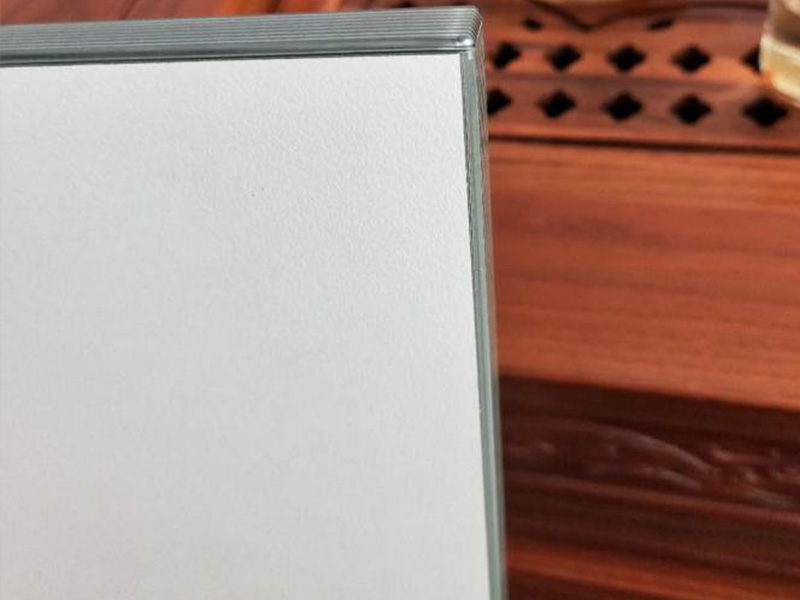

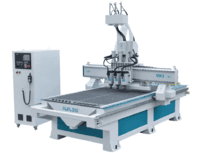

Product applicationEdge banding machine in woodworking is used in banding edge of desks,cabinet,wardrobe and straight line furniture.The edge banding tape can be PVC,melamine,wood based works.

Machine functionPre-heating,pre-milling, gluing,end cutting, rough trimming, fine trimming, round corner, scraping, buffing.

Function display:

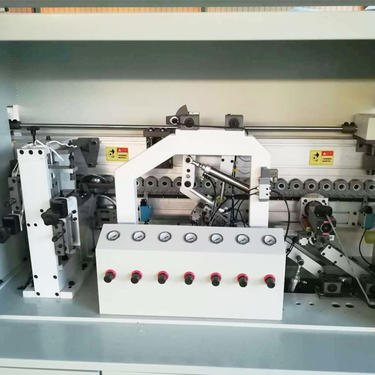

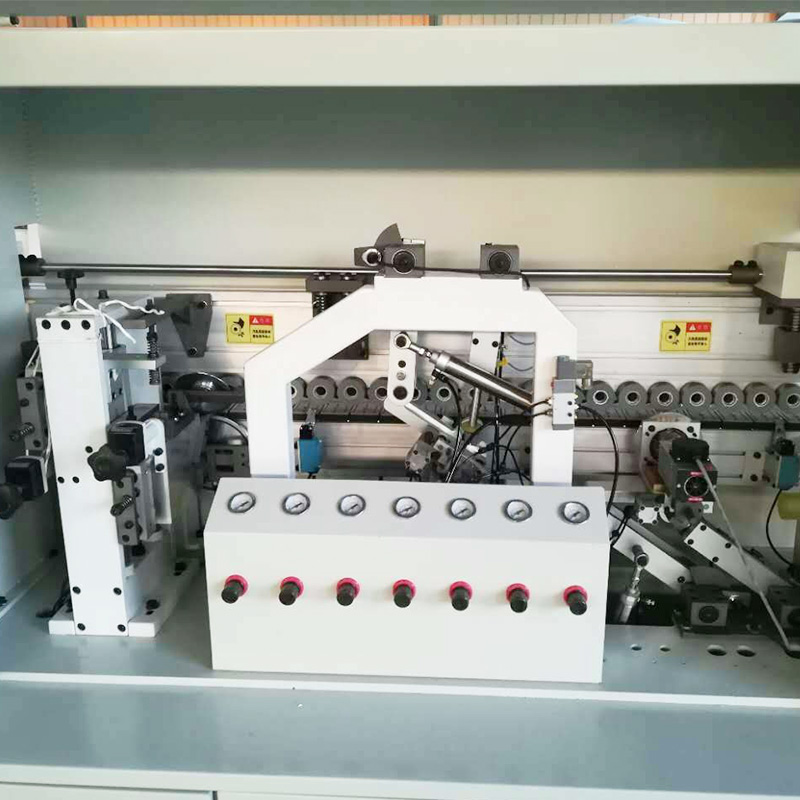

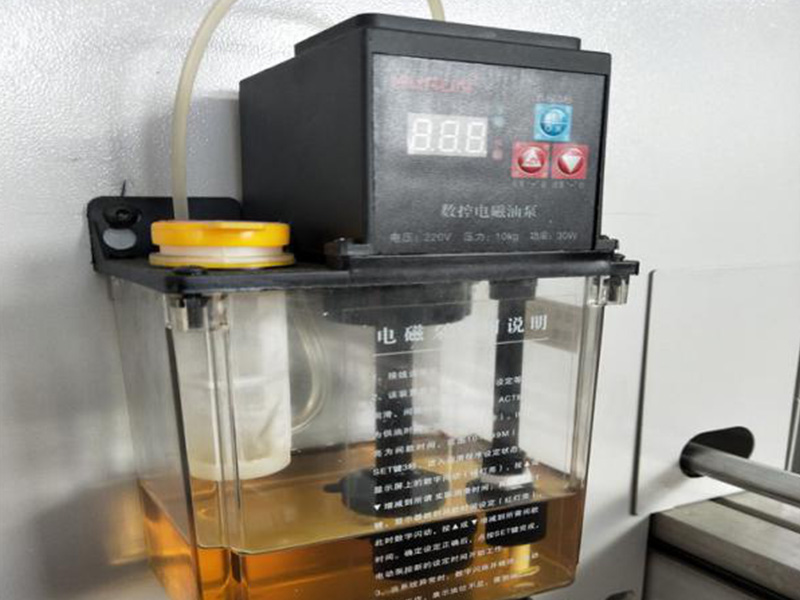

Machine parts:

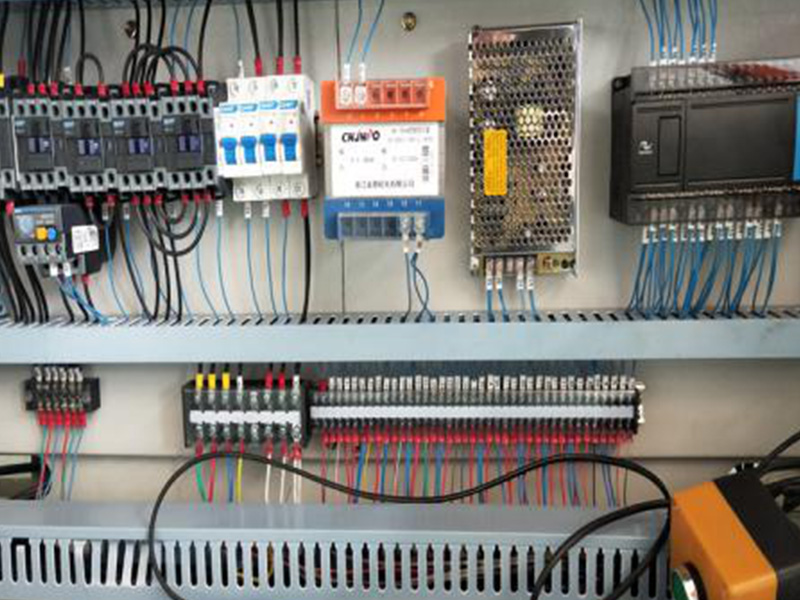

1.Delta touch screen with PLC controller for machine control system

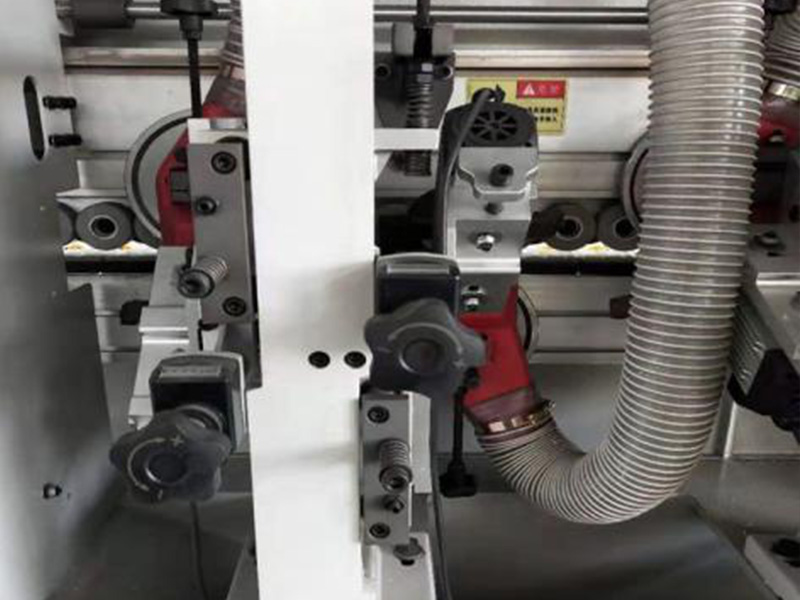

2.Premilling

Pre-milling function: The main function is to deal with the edge-sealing effect caused by rough and non-vertical surface of the plate. The pre-milling uses 2.2KW*2 high-speed variable frequency motor, the speed can reach 12000 rpm, which makes the milling edge effect more advantageous. It is equipped with 120mm diamond. The blade has sharp edges and is perfectly durable.

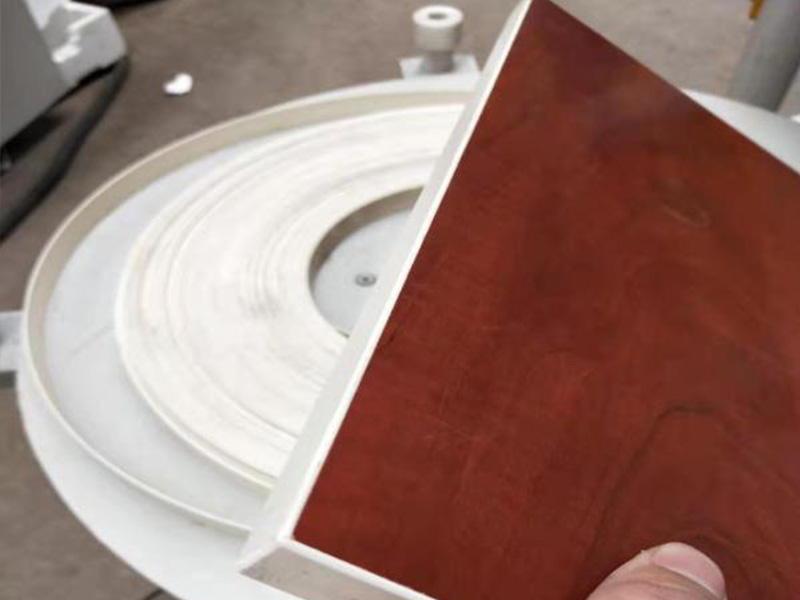

3.Gluing

Gluing function: use large-capacity glue pot, can accommodate 2ML granular sol at one time, aluminum pot non-stick pan, no need to clean, rubber door control uses cylinder automatic device, plate goes to automatic open glue, plate glue finishes automatically close It avoids the entry of impurities into the glue coating port. In the latter process, the edge-sealing sheet is bonded by four-wheel extrusion. The No. 1 wheel is a self-rotating wheel, which has the effect of evenly pressing the skin. The rear three wheels are angled and inclined. Sew to make the bonding effect more perfect.

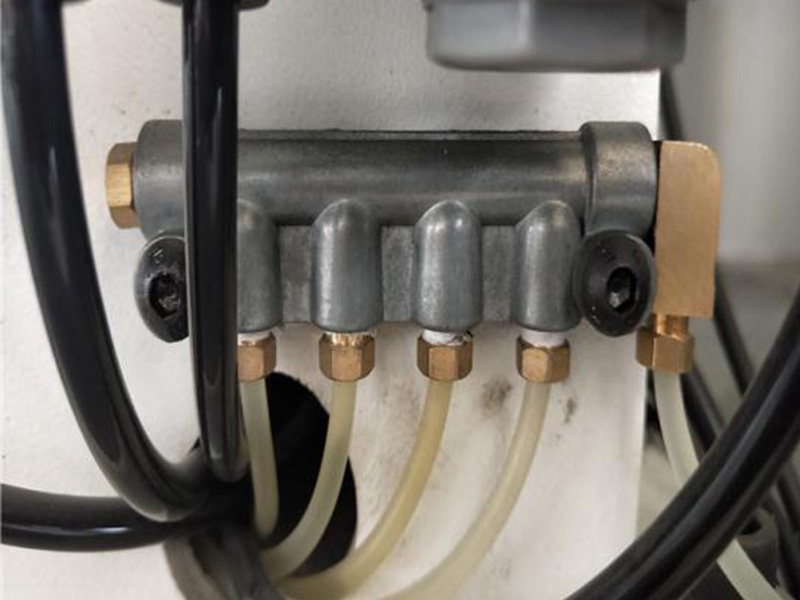

4.Barrier cylinder

Barrier cylinder: The automatic edge banding machine is equipped with the function of end cutting. There is a certain distance limit for the continuous plate in the work. The automatic blocker is installed without observing the distance of the plate. The cylinder will automatically send the signal through the PLC. Turn it off to make the operation easier.

5.End cutting

6.Rough trimming, fine trimming, scarpping

7. Buffing, conveying, lifting

8.Machine bed is heavy steel plate frame welding

NO. | Item |

|

1 | Edge tape width | 12-50mm |

2 | Edge tape thickness | 0.4-3mm |

3 | Workpieces thickness | 10-50mm |

4 | Min workpiece length | 150mm |

5 | Min work piece width | 60mm |

6 | Pre-milling the shortest workpiece | 300mm |

7 | Total power | 16.86kw |

8 | Air pressuer | 0.6MPa-0.8Mpa |

9 | Gluing pot heating power | 1.5kw |

10 | Board preheating power | 0.15kw |

11 | Gluing box transmission power | 0.55Kw |

12 | Conveyor motor power | 1.5Kw |

13 | Premilling motor power | 2.2Kw*2 |

14 | End cutting motor power | 0.35Kw*2 |

15 | Rough trimming motor power | 0.7Kw *2 |

16 | Fine trimming motor power | 0.7Kw*2 |

17 | Buffing motor power | 0.18Kw*2 |

18 | Workpiece conveyor speed | 15-23m/min |

19 | Net weight | 2600Kg |

20 | Machine dimension | 7200*1100*1600mm |

21 | Packaing dimension | 7400*1300*1800mm |

22 | Warranty | 1 year |