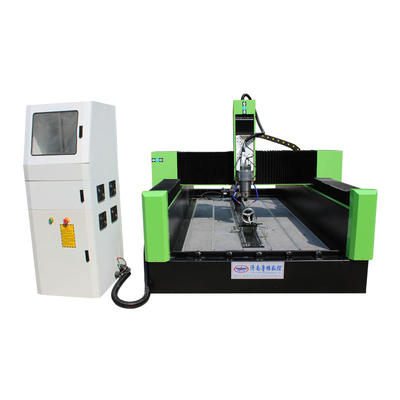

TM-2480C-2 Vacuum membrane press machine Semi auto with double stations for PVC door production line

External dimensions | 5,800 x 1,850 x 1,350mm |

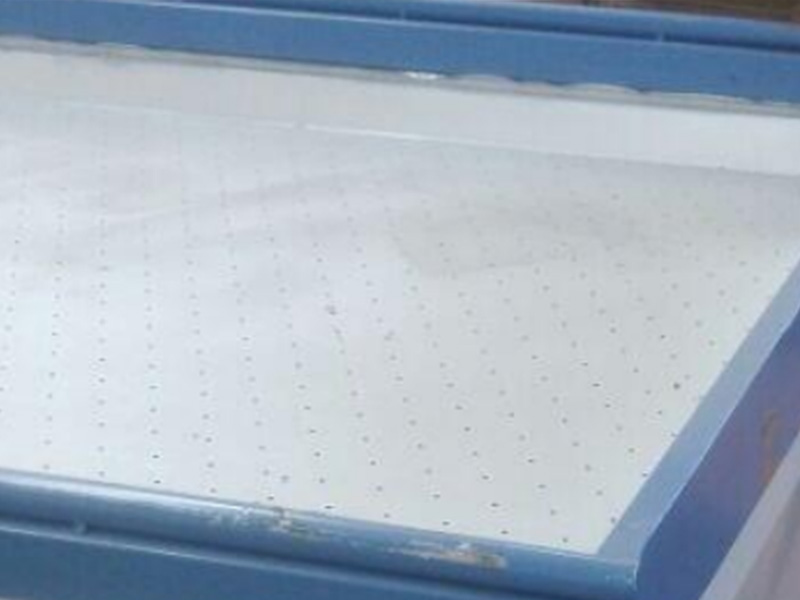

Worktable dimensions | 2,550 x 1,150 (1,300) x 50mm |

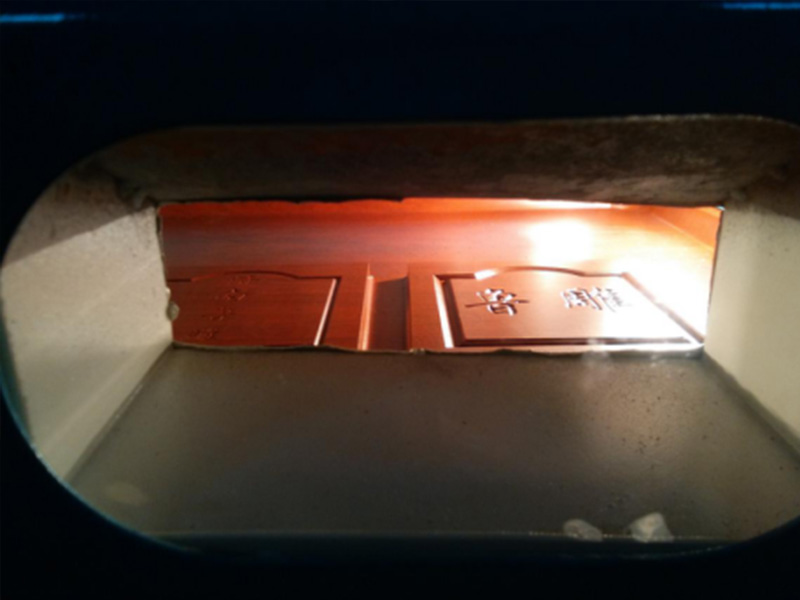

Max. processing height | 80mm |

PVC thickness | 0.1-0.35mm |

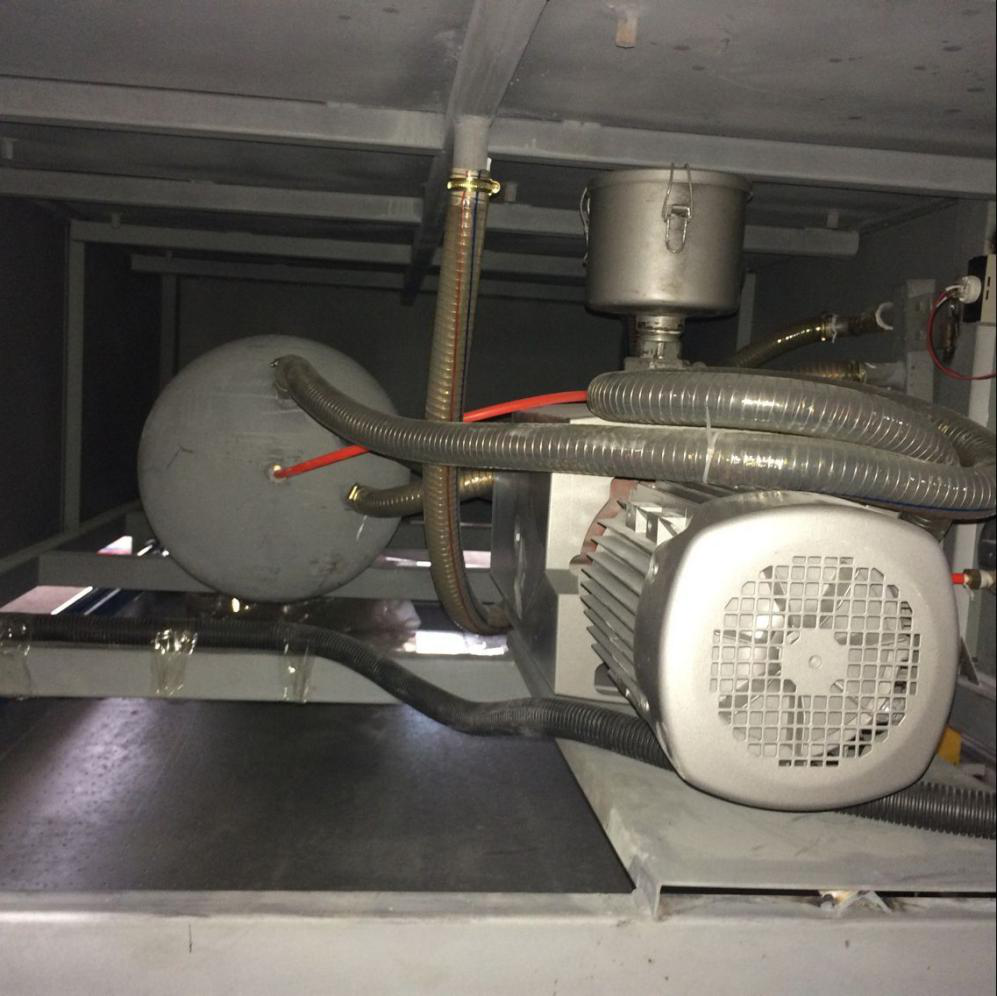

Max vacuum press | -0.1Mpa |

Vacuum pump | 2.2KW |

Total power | 20kW |

Actual power | 5kW |

Total weight | 1200kg |

Package | :Standard export wooden box |

Payment | TT |

Warranty | 1 year |

PVC film MDF board, Plywood, OSB board, and other wooden materials with breathable It is applicable to cover furniture, sound box, cabinets, relief door, decorative panels and all kinds of baroque decorative surfaces with PVC films and natural veneer and hot stamping foils.

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts