Fireproof

Acid and alkali resistance performance

Toughness

Weather resistance

Low noise

Portability

Environmental Protection

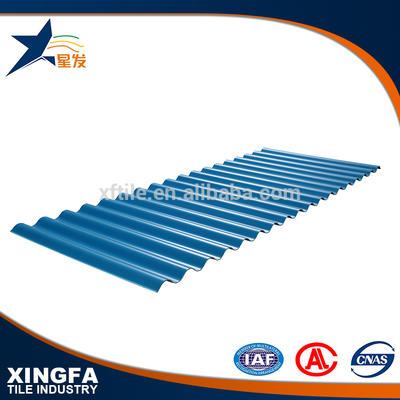

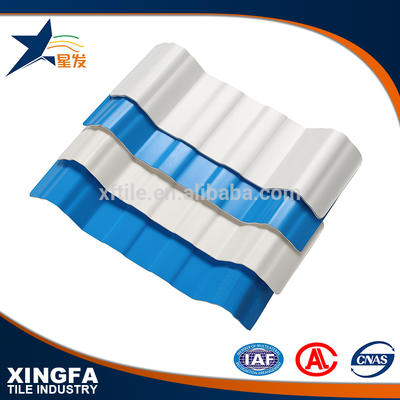

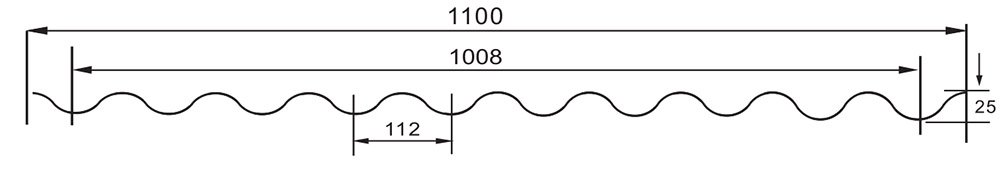

UPVC Corrugated roof sheet B1100

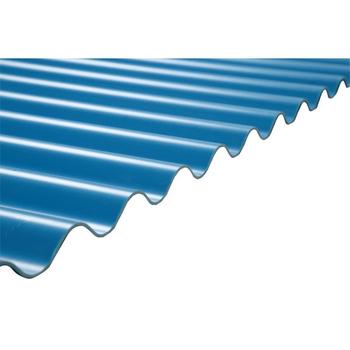

UPVC Corrugated roof sheet

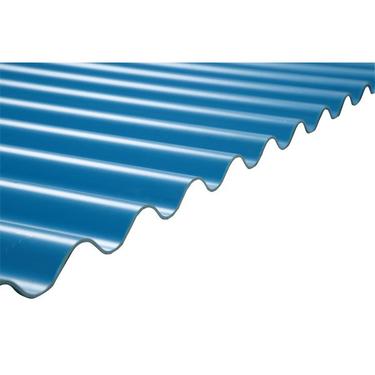

Selecting the high-quality raw material, with strict inspection and monitoring of the company,the product is made in a process with extrusion technology.The main raw material is PVC resin supplemented with anti-UV additive. It is occupied with excellent fire resistance,weather resistance and electrical insulation,which is an excellent anti-corrosion material.

In the heavily polluting industries and heavy acid rain areas,using UPVC anti-corrosion tile can free the trouble of rust and leaking roof once and for all.Provide the quality guarantee for 15 years.

B1100 Specification

Model | B1100 |

Width | 1100mm |

Efficient width | 1008mm |

Thickness | 1.0mm,1.2mm,1.3mm,1.5mm,2.0mm,2.5mm,3.0mm |

Length | Customized (20'container 5.8 meter, 40'container 11.8 meter) |

Applications | factory roof, warehouse roof, wall panel etc... |

Surface finishing | ASA coated,Embossed type,standard type. |

Layer | Single layer, Three layers, Four layers |

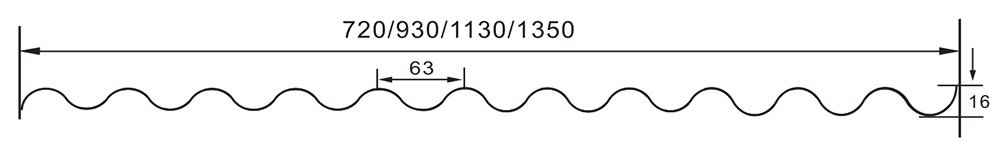

B720/B930/B1130/B1350 Specification

Model | B720/B930/B1130/B1350 |

Width | 720/930/1130/1350mm |

Efficient width | 630/840/1040/1260mm |

Thickness | 1.0mm,1.2mm,1.3mm,1.5mm,2.0mm,2.5mm,3.0mm |

Length | Customized (20'container 5.8 meter, 40'container 11.8 meter) |

Applications | factory roof, warehouse roof, wall panel etc... |

Surface finishing | ASA coated,Embossed type,standard type. |

Layer | Single layer, Three layers, Four layers |

700 size

1100 size

UPVC roof color

UPVC TEST REPORT

Num. | Test item | Test method | The test condition | Test result |

1 | Tensile strength | ISO 527-1:2012 & ISO 527 -2:2012 | Testing speed: 50mm/min | 23.1 Mpa |

2 | Flexural strength | ISO 178:2010/Amd.1:2013 Method A | Test speed: 1mm/min | 50.9 Mpa |

3 | Impact Resistance | With reference to GB/T 8814-2004 Section 5.7, Section 6.7 and client’s requirement | -10°C, 1h | Number of specimen failures: 0 |

4 | Vicat Softening Temperature | ISO 306:2013 Method B 50 | Rate of temperature: 50K/h | 77.0°C |

5 | Effects of liquid chemicals | ISO 175:2010 | Temperature: 23°C | No visual change |

ISO 175:2010 | Temperature: 23°C | Visual discoloring, but no other visual change | ||

ISO 175:2010 | Temperature: 23°C | No visual change | ||

6 | Light Ageing Test – Xenon-arc Exposure | ISO 4892-2:2013 cycle 4 & ISO 105-A02:1993/Cor.2:2005 & ASTM D2244– 15a | Exposure period: 1000h | Grey scale: 3 |

7 | Dimensional Stability | With reference to ASTM D1204-14 and client’s requirement | 100℃,60min→23±2℃, 50±5% RH, 60min | Direction of arrow: -0.6% |

NO. | Test Item | Test Method | Result | Conclusion | |

1 | Dimensional Stability | With reference to ASTM D1204-14 and client’s requirement | Direction of arrow | -0.6% | / |

Perpendicular to Direction of arrow | 1.6% | ||||

2 | Flexural Test | ISO 178:2010/Amd.1:2013 Method A | Flexural Strength | 50.9MPa | / |

Flexural Modulus | 4290MPa | ||||

3 | Striker Impacted by a Falling Weight | With reference to GB/T 8814-2004 Section 5.7, Section 6.7 and client’s requirement | Number of specimen failures: 0 | / | |

4 | Tensile Test | ISO 527-1:2012 & ISO 527-2:2012 | Tensile Stress at Break | 23.1MPa | / |

Nominal Tensile Strain at Break | 38% | ||||

5 | Vicat Softening Temperature | ISO 306:2013 Method B50 | 77.0℃ | / | |

6 | Effects of liquid chemicals | ISO 175:2010 | See Result | / | |

7 | Light Ageing Test-Xenon-arc Exposure | ISO 4892-2:2013 cycle 4&ISO 105-A02:1993/Cor.2:2005 & STM D2244-15a | See Result | / | |

Note: Pass: Meet the requirements;

Fail: Does not meet the requirements;

/: Not Apply to the judgment.

About our Company

Contact

Supplier

Aluminum Composite Panels

Balustrades & Handrails

Bathroom

Boards

Building Glass

Ceilings

Countertops,Vanity Tops & Table Tops

Curtain Walls & Accessories

Decorative Films

Door & Window Accessories

Doors & Windows

Faucets, Mixers & Taps

Flooring & Accessories

Formwork

HVAC Systems & Parts

Kitchen

Ladders & Scaffoldings

Metal Building Materials

Mosaics

Plastic Building Materials

Quarry Stone & Slabs

Real Estate

Stairs & Stair Parts

Tiles & Accessories

Door, Window & Accessories

Stone