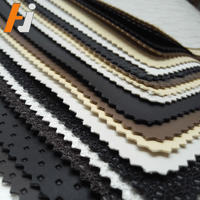

1.8mm & 2.0mm PU Microfiber Leather for Safety Shoes & Work Boots

WINIW microfiber synthetic leather can fully comply EN ISO20345:2011 standard (water vapour permeability, water absorption) S1 and S2 standard for safety shoes and work boots, high mechanical strength and excellent durability, eco-friendly, is the best leather substitute material, can replace genuine leather perfectly for safety shoes and work boots.

With excellent physical and chemical performance, WINIW microfiber leather has been the best alternative material of leather upper for safety shoes, work boots, military shoes, security boots, etc.

WINIW Microfiber PU Leather and Microfiber Suede Leather for safety shoes & boots can meet below requirements required by EN ISO20345:2011 standard for the safety shoes leather upper:

1. Tear strength at least 120N.

2. Water vapour permeability min 0.8mg/(cm2.h).

3. Water vapour coefficient min min 15mg/cm2.

4. Water absorption max 30%.

5. Water penetration max 0.2g.

| Color | Customized |

| Package | Usually in 30m/50m per rol, or customize. |

| Delivery time | Usually within 15 - 25 days. |

| Customized | Yes |

| Applied field | Men & Women’s Shoes; Military shoes; Work shoes; Daily shoes; Boots. Literature and sports shoes; Travel shoes; Medical corrective shoes; Children shoes |

| Product features and features | 1,Super anti-abrasion,high quality material,suit many applications requirement. 2,WINIW leather have great waterproofness, breathability and moisture absorption, making feet breath freely andfeel comfortable. 3,Excellent genuine leather or unique textile effect on the WINIW leather suface. 4,Rich in resilience and elastic, always looks beautiful as new. 5,Resistant to bending, Soft and full hand feelings. 6,Unique and fashionable designs, Crazy Horse, Oily Leather, Wax Touch, Color Changing, Polishing,Nubuck series represent natural, nostalgic, and elegant styles. Crystal, Enamel and Textile series reflect strong flavors of fashion trend. 7,Very nice torsion resistance under normal temperature and cold resistance; Very nice performance in gluing process with a great smooth surface. 8,High dry and wet rub fastness, no peeling and color fading on surface. 9,Animals-friendly, vegan leather,protect animals well. 10,Easy cutting and good shoes shape maintenance, which fully meet the requirements of footwear manufacturing. 11,Regular size in rolls, uniform thickness, high usage ratio, high production efficiency. 12,Reach Eco-friendly standards: ROHS,EU REACH,EN-20345,etc. |

WINIW have two styles of Microfiber Leather, which is Microfiber Synthetic Suede Leather and Microfiber PU Coated Leather, made of nylon (polyamide) and PU (polyurethane) through high-tech production technology, has same looks and same feel as cow suede leather, eco-friendly, is the best suede leather alternatives and best substitute of suede leather!

1. Benzene-free, environmental-friendly.

2. Excellent abrasion resistance.

3. High tear strength.

4. High moisture absorption.

5. Resistant to acid and alkali.

6. Resistant to climate wear-and-tear.

Contact

Supplier