128kg/m3 density insulation ceramic fiber blanket for sale

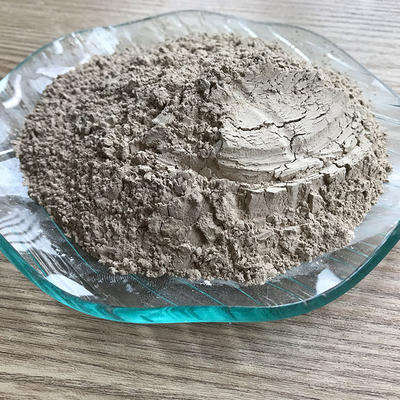

What is the pictures of ceramic fiber blanket ?

100% actual picture

What is the descriptions of ceramic fiber blanket ?

1.Ceramic fiber blanket is made of high quality alumina-silicate ceramic fiber by using double side needling methods which improve the tensile strength and the flatness of the ceramic fiber blanket.

2.Ceramic fiber blanket contains no organic binders which guarantee the stability and constructability of the ceramic fiber blanket at both high temperature and low temperature.

What is the data of ceramic fiber blanket?

Grade | Common | Standard | High Pure | High AluminA | Zirconium | |

Max. Temperature (°C) | 1100 | 1260 | 1260 | 1360 | 1450 | |

Working Temperature (°C) | < 1000 | 1150 | 1180 | 1260 | 1350 | |

Color | Pure White | Pure white | Pure white | Pure white | Pure white | |

Density (kg/ m3) | 96/128/160 | 96/128/160 | 96/128/160 | 128/160 | 128/160 | |

Shrinkage on heating (%) (24 hours, density as 128/m3) | -4 | -3 | -3 | -3 | -3 | |

Thermal conductivity by mean temp. (w/m.k) (density as 128kg/m3) | 0.09(400°C) | 0.09(400°C) | 0.09(400°C) 0.16(800°C) | 0.12(600°C) | 0.16(800°C) | |

Tensile strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | 0.04 | |

Chemical composition (%) | AL2O3 | 44 | 46 | 47-49 | 52-55 | 39-40 |

AL2O3+SiO2 | 96 | 97 | 99 | 99 | - | |

AL2O3+SiO2+ZrO2 | - | - | - | - | 99 | |

ZrO2 | - | - | - | - | 15-17 | |

Fe2O3 | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | |

Na2O+K2O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | |

What is the feature of ceramic fiber blanket ?

1.Excellent heat insulation,

2.Excellent chemical stability,

3.Shock and chemical attack resistant,

4.Low thermal conductivity,low heat storage,

5.Excellent thermal stability and thermal shock resistance,

6.Excellent tensile strength,

7.Excellent thermal insulation,fireproof and sound absorption.

What is the Applications of ceramic fiber blanket?

1.Ceramic industry:

Kiln car insulation and seals,

Continuous and batch kilns

2.Steel industry:

Heat treating and annealing furnaces,

Furnace door linings and seals,

Soaking pit covers and seals,

Furnace hot face repairs,

Reheating furnace and ladle covers

3.Refining and petrochemical industry:

Reformer and pyrolysis lining,

Tube seals,gaskets and expansion joints,

High temperature pipe,duct and turbine insulation

Crude oil heater linings

1.Solid packing and overall stuffing can prevent the form and jarring.

2.Different products have different froms of packaging and absolutely in line with internatianal standards.

3. Package Informations: 1.Carton box outside and plastic bag inside 2.According to customer's requirements

Packaging

Shipping

1. FEDEX/DHL/UPS/TNT for samples.

2. By Sea for batch goods.

3. Customers specifying freight forwarders or negotiable shipping methods!

4. Delivery Time:3 days for common shape samples,Within7-15 days for batch goods.

Payment Terms

1. Payment: T/T, Western Union,LC; Usually 30% deposits,70% balance before delivery or negotiations to solve.

2. MOQ: Usually 1 roll,

3. Quality Warranty: 1 years,

4. Package Informations:Carton box outside and plastic bag inside or according to customer's requirements .

Professional fireclay brick team.

We have being specialized in producing refractory fireclay brick for more than 15years so that we can guarantee a stable quality.

Guaranteed quality.

Our production process conforms strictly to the requirements of ISO9000 quality management system.

Guarantee samples quality same as your ordering production quality.

Sound after sales service.

Production of goods are finished, thoughtful provide products and packaging photos for customers.

All our products have 1 year warranty period.

Competitive price.

Provide the reasonable logistics for customers to save every penny.

Prompt reply.

We provide 12 hours’ consultation service,we are ready to answer your consultations at any time.

Factory view

Henan Lite Refractory Material Co., Ltd is located in Zhengzhou,Henan province,which is one of the main refractory production bases in China. Pengfei Zhang the manager of our company,has been engaged in refractory material industry for more than 15 years.In the technological team there are more than 10 senior designers and engineers,more than 20 technicians.

Main products include different kinds of refractory brick:Fire Clay Brick, High Alumina Brick, Light Weight Insulating Brick,Corundum Brick,Mullite Brick Refractory Balls etc.They are widely used in Iron and steel, Nonferrous metals, Building materials(Cement,Glass,Ceramic), Petrochemical, Energy & Incineration etc industries. Our products have been exported to India,Turkey,Vietnam,Malaysia and Kazakhstan etc.

“Science-Technology Innovation, Cooperation for both-winner”, Henan Lite Refractory Material Co., Ltd will do the best for the clients in a timely and effective way.

Our certificates

Our mainly common products:

Light weight high alumina brick

Common refractory brick

Special refractory brick

Refractory ball

Unshaped refractory

Ceramic fiber product

1.We team have a production background of more than 15 years,workers and technical staffs team who enjoy rich experiences and skillful operations. They guarantee a stable and continuous output of high quality refractory brick.

2.The annual output of our factory can reach more than 50000 tons. The alumina content of our fire brick ranges from 38% to 85%. Our factory has the largest annual output in the whole country of one single product.

About quality

Quality assurance 1 year

About sample

It is free , and we can also send products catologue and price list to you .

By sea and by carrier service ,all ok.

About Delivery

Common case :within 25 days after deposit ;

Special case :depends on the customer's requirments.

About payment

L/C ,T/T,D/A ,D/P,Western Union,MoneyGram all yes ,other could be discussed.

About price

Choose us ,products price advantage than the industry leading thirty percent .

About MOQ(minimum order quantity)

No limit

About OEM (original equipment manufacture)

Yes ,the size,density,chemical composition can be customized.

We will give you professional suggesttion and service.

About order

Contact

Supplier