2.54mm Pitch Pin Header and Socket PCB Connector Customized

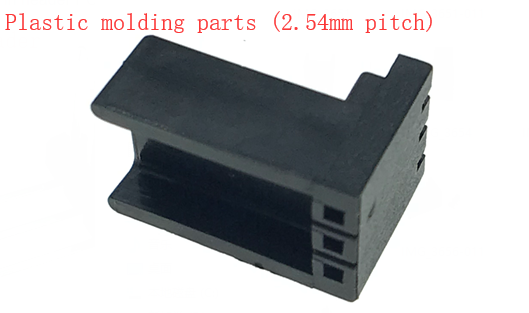

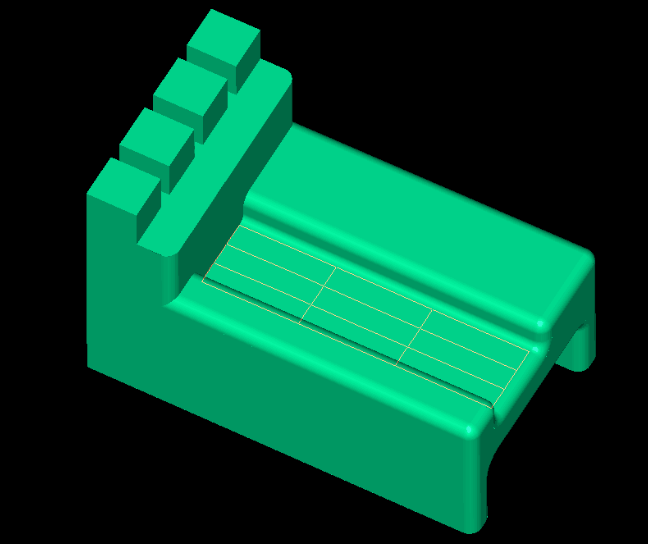

This is a special customized Pin header PCB Connector. It is combined with one pin header and a plastic molding parts.

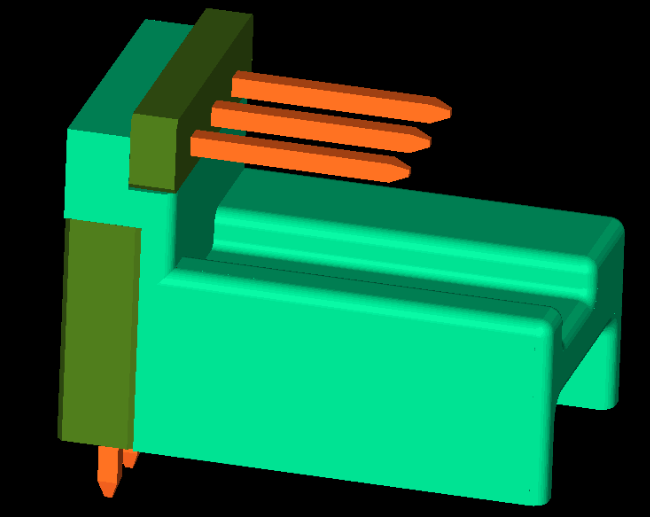

The pin header is a 2.54mm pitch right angle pin header, it is made in the regular production process——make the pin and the insulator assembled by automatic machine and then bending in the same automatic machine but not the same process. The other part of this model is a plastic molding part. This part is made directly by one mold, the whole mold come out after plastic raw material being put into the molding machine. All these processes are automatically. After these two parts are ready, the next process is assembly. The following the assembly one in one view.

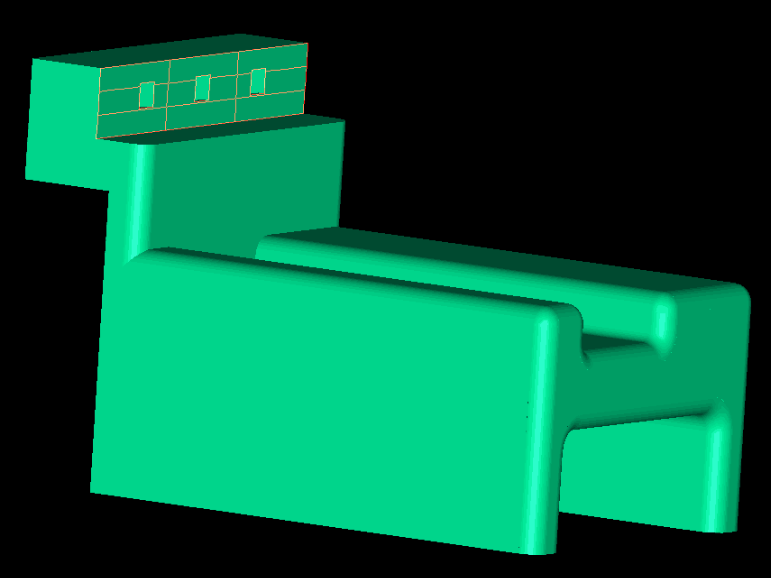

Every product has been modified several times before the final confirmation, our this model is no exception. When first designing this product, considering some special application requirements, our customer made it in a more complicated design. This is the first design below.

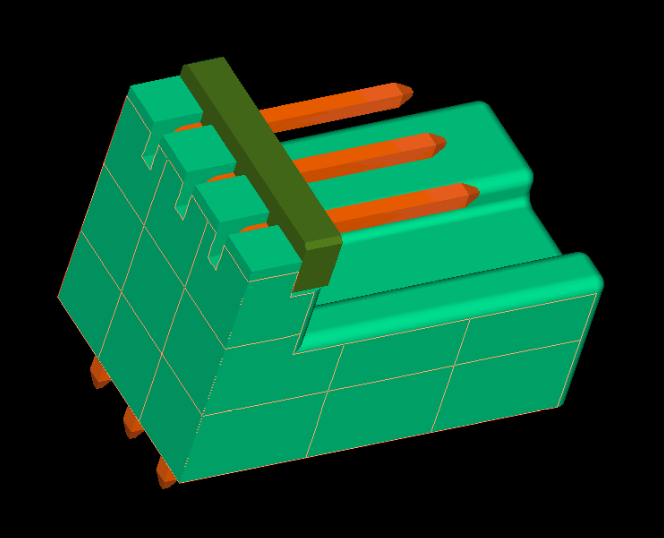

While we received the drawings, and got more information from our customer, we found it can be designed in a more easy shape. Not only can meet all requirement of application, but also help our customer save some cost. From the initial drawing, we can see that this prodcut is made of three seperated parts. To our supplier, every single part has to be taken into account when we make appraisal cost. One more part not only means there is a high probability that we need to make an additional set of molds, but more production control cost will be added. Considering all these aspects, we put forward a better plan and our engineer make a design to solve this problems. Pictures follow are our design for our customer.

We show this case here just for telling our new customers that we have the ability to help you make a better design in our manufactuering viewpoint. We are expert in making connectors, we know how to design products in a more economize way with the quality assurance. Don't hesitate to pass us your inquiry, believing that we can be your best business partner. Our foreign trade policy is base on equality and mutual benefit and exchange of needed goods. Warmly welcome you!

SHIPMENT

Contact

Supplier