2019 New cnc gesac tools turning insert with external turning part blade

Supplier Info.

Company Name: NIGEL Co., Ltd

Registration Date:

2017

Country / Region:

/ China

Main Products:

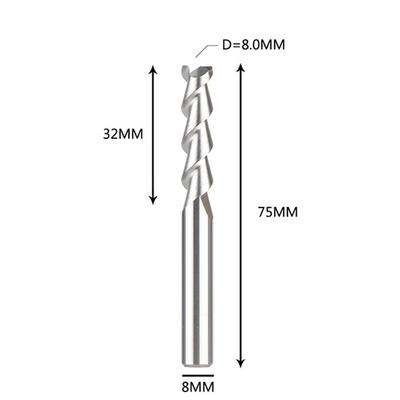

milling cutter,drill bit,drill bit set

Product Detail

Product Description

| item | TLJ120402 |

| Material | Tungsten Carbide |

| Color | As picture |

| Usage | External Turning Tool |

| Hardness | HRC90 |

| Coating | N/A |

| Quality | p30 virgin material carbide inserts turning tool |

| Grade | P30 grade for YT5 carbide inserts turning tool |

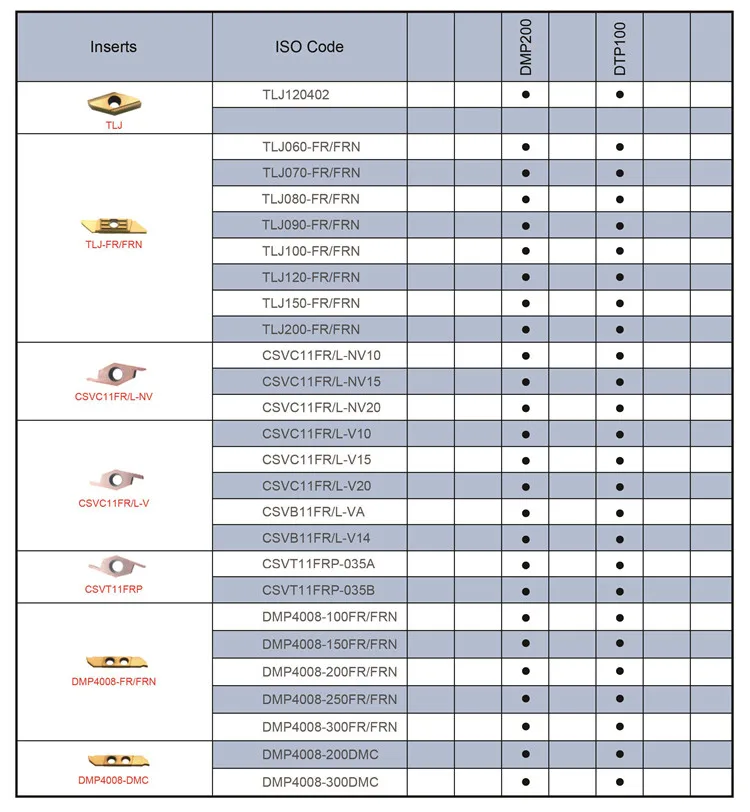

Related Inserts

FAQ

1. What’s your payment terms?

A:T/T or L/C.

2. What’s your delivery time?

A:Usually we will arrange the shipment in 7-15 days.

3. How about the packing?

A:Usually we provide the packing as 25kg/bag or carton. Of course, if you have special requirements on them, we will according to you.

4. What is loading port?

A:Usually is Shanghai, Qingdao or Tianjin.

5. Is your company accept customization?

A:OEM and ODM are available. And we have our own professional R&D team servicing for you.

6.If you want to know more about our company?

A:With no Hesitate, directly contact us

NIGEL Co., Ltd not only pays attention to domestic product standards, our milling cutter has passed international certificates. The special CVD or PVD coating has reduced its friction coefficient.

We promise on-time delivery for milling cutter, so you can run your business without any delay. The special CVD or PVD coating has reduced its friction coefficient.

Contact

Supplier

Contact us

Tell us your Buying Requirements

You Might Also Like