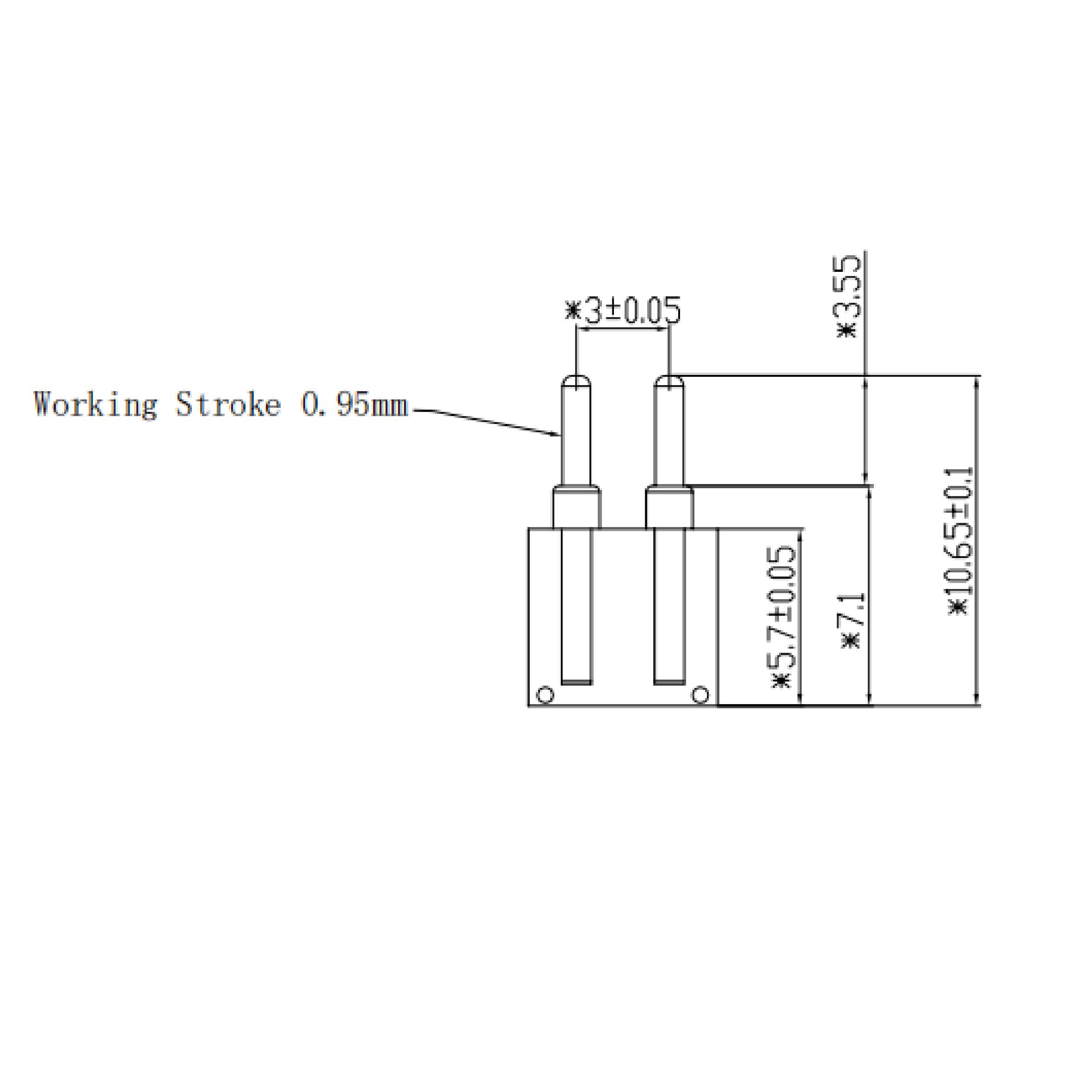

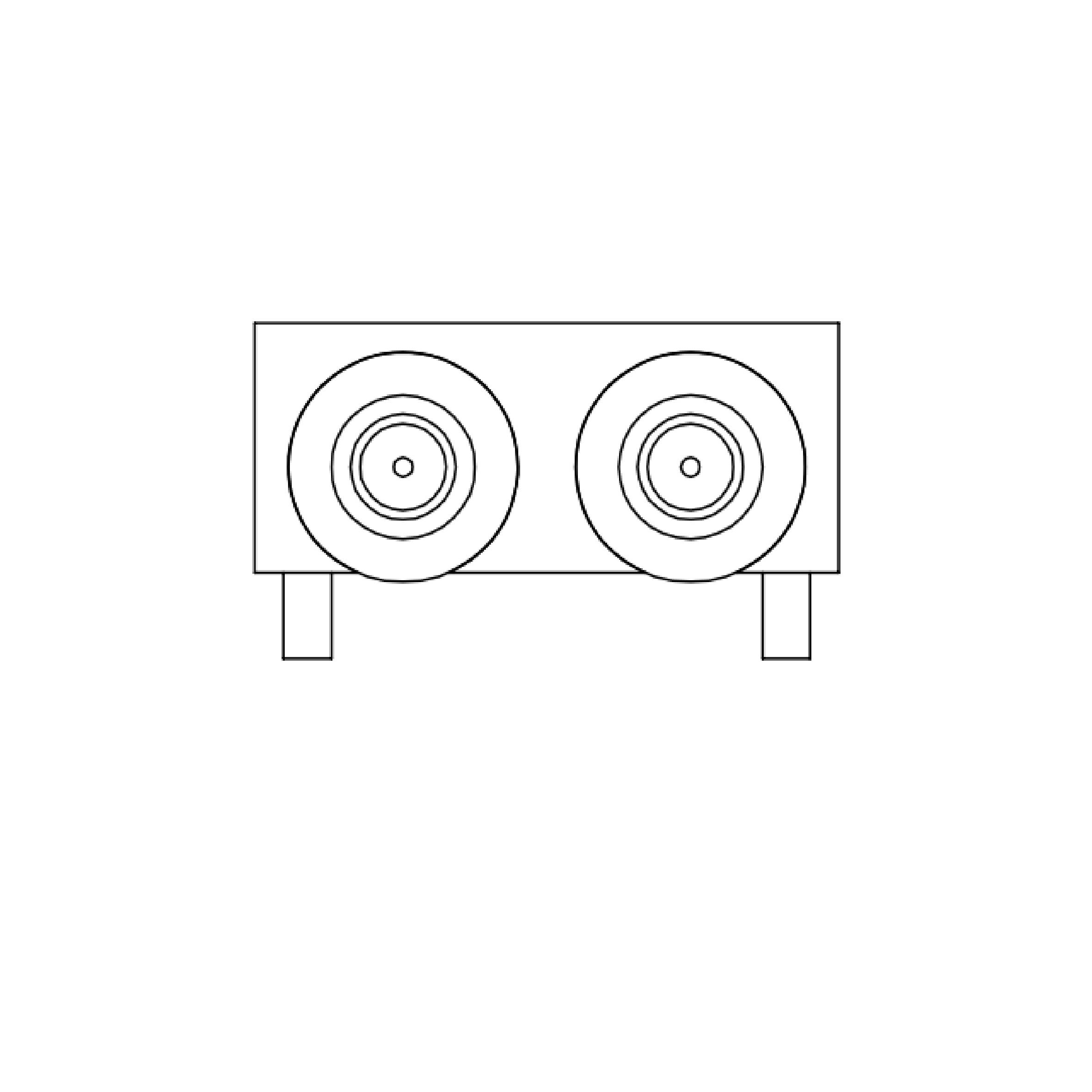

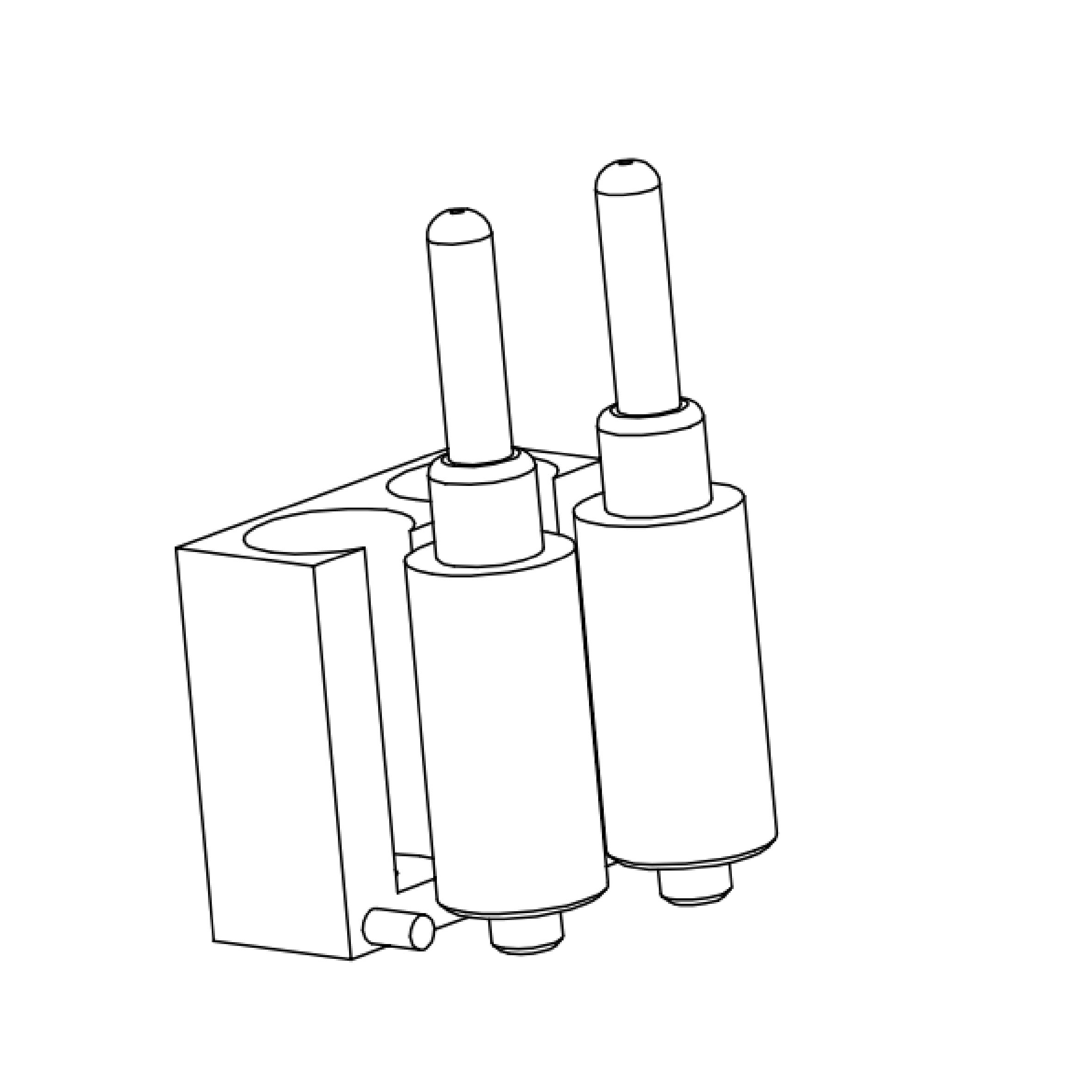

3.0mm 2pin Customized Pogo Pin Connector

| Rated Current | 5A every single pin |

| Rated Voltage | 12V |

| Contact Resistance | 50 Mohm Max at normal working height |

| Plunger Material | Brass 3604 |

| Spring Material | SUS304 Gold-plated |

| Insulator Material | PA46 |

| Plunger Plating | Gold over Nickel |

| Spring Force | 100gf |

| Durability | 20,000 cycles Min |

DETAILS

APPLICATION

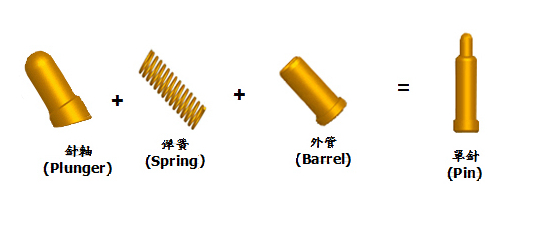

The Pogo Pin pogo is a special connector with a basic construction consisting of a plunger, a spring and a barrel. The plunger is crimped to hold it in the tube, and the spring provides contact force to establish an electrical connection between the pin and the docking part.

The application of pogo pin connector:

Smart wearable devices: smart bracelets, smart bracelets, pet locators, Bluetooth headsets, smart wristbands, smart shoes, smart clothes, smart glasses, smart bags, etc.

Smart home, smart appliances, air purifiers, automatic controllers, etc.;

Medical equipment, wireless equipment, data communication equipment, telecommunications equipment, automation and industrial equipment;

3C consumer products, notebooks, tablets, PDAs, handheld data terminals, etc.;

Aviation, aerospace, military communications and military electronics;

Automotive, car navigation, test and measurement equipment, etc.

CUSTOMIZED CASE of this model

Provide product feature specifications or prototypes.

This model is customized by one of our client from South American. We got their inquiry in Oct.2018 by sending us email directly. They asked us if we could customized the pogo pin they need. For sure we can make it, and the only thing we need is your product feature specification of prototypes.Finally they offered us the drawing.

Our R&D team evaluates project data or specifications to determine feasibility.

After we received the drawing, we passed it to our R&D team. They helped to put forward specific plans. Our sales team negotiated with clients and comfirmed cooperation solutions.

Both parties sign a development contract.

Confirm with the customer that the plan is feasible and the two parties sign the development contract.

The customer prepaid the development fee.

Customer paid the development fee after signing development contract. In the early stage of development, the input cost is required. Before ensuring that the customer's order quantity is enough to cover the development cost, we and the customer determine that the pre-development cost is borne by the customer. In the later period, the demand of customers will increase, and the related development costs will be profitable on the unit price of the products. Of course, there is a difference in the way customers can't, and here is just a case.

Hardware and software design and system debugging according to specifications.

Mold making of this product. Including housing mold, turning machine mold, and production pallet mold. We work with professional mold companies to provide mold companies with the requirements and make them according to the drawings. The mold making of this product was completed and debugged, and all passed smoothly.

After the functional test of the system, submit it to the customer for confirmation.

Sample preparation is completed, and dimensional and performance tests are performed to meet the customer's first edition drawing requirements. The sample was sent to the customer and the customer adapted it, but due to the customer's need for greater elasticity, a second commissioning was performed.

Customer acceptance.

The entire case was sampled twice and the sample passed the test. It lasted for 6 months and is currently in mass production.

SHIPMENT

Contact

Supplier