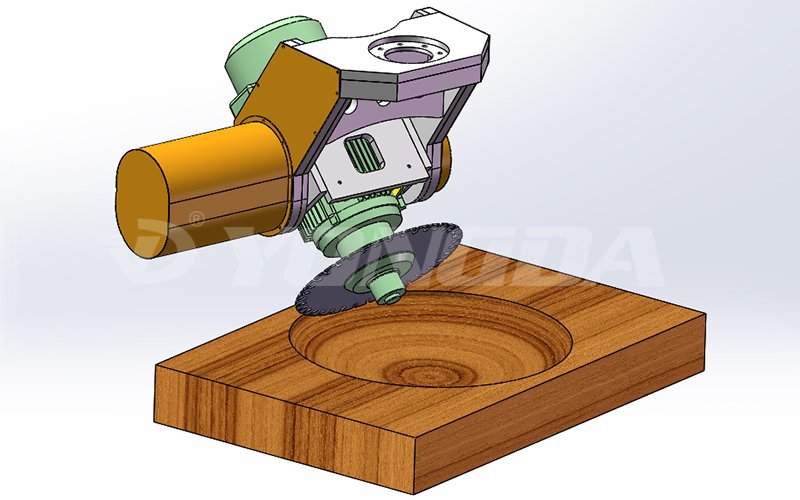

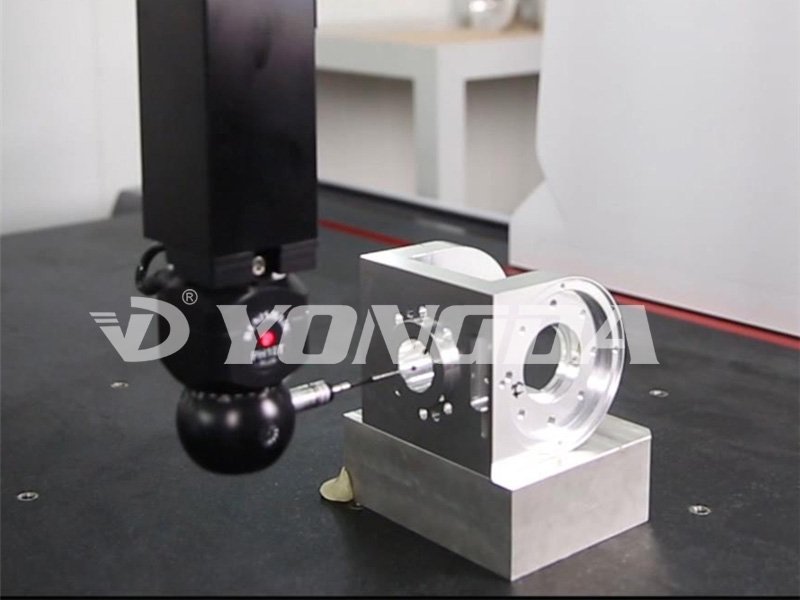

engraving

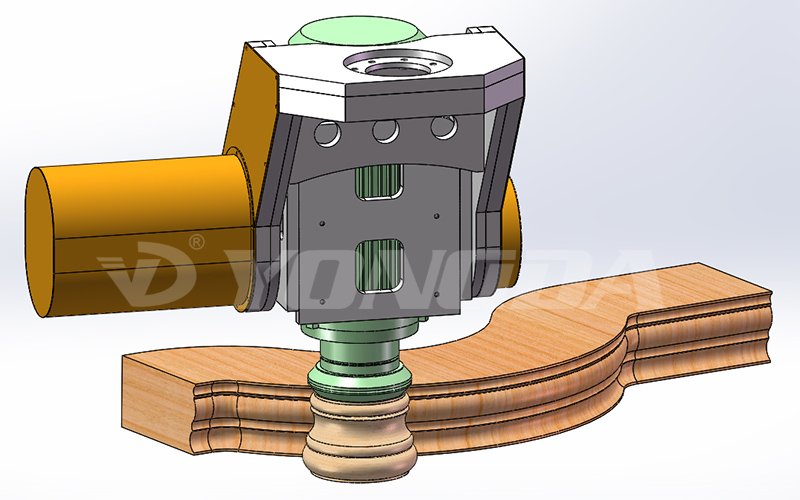

carve

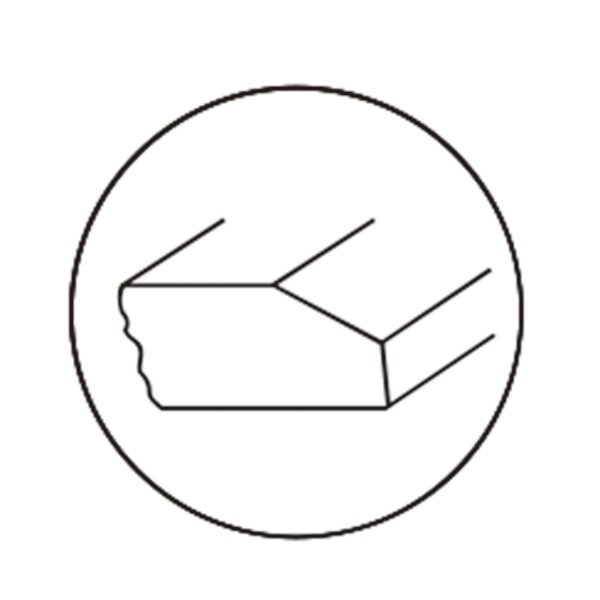

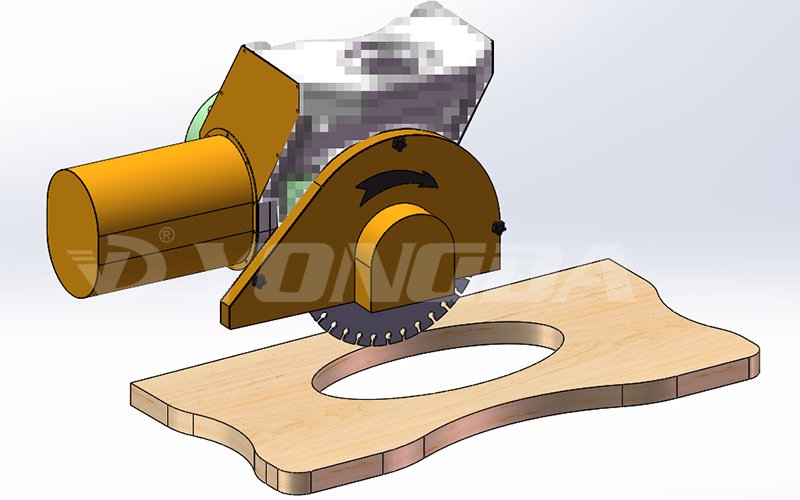

45 degree cutting and polishing

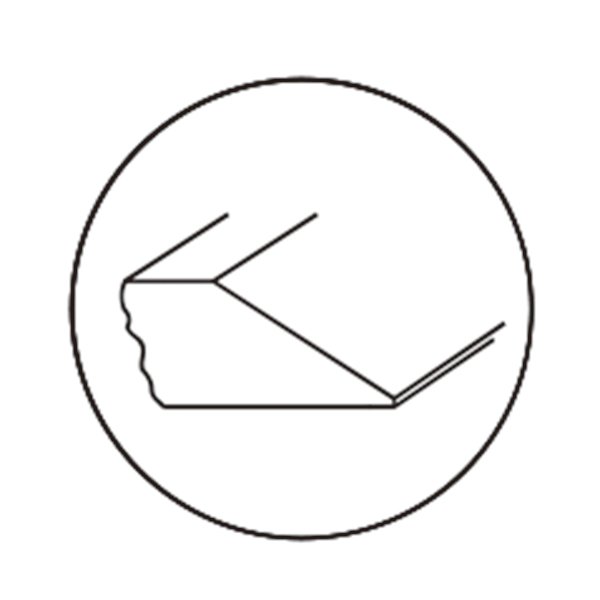

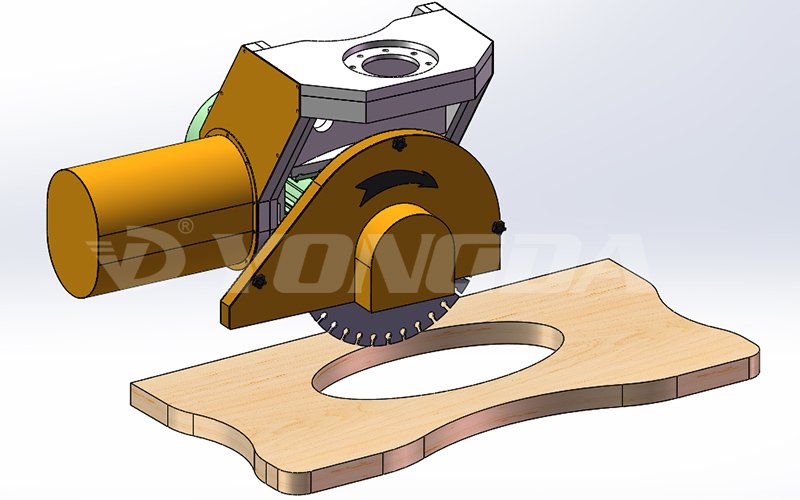

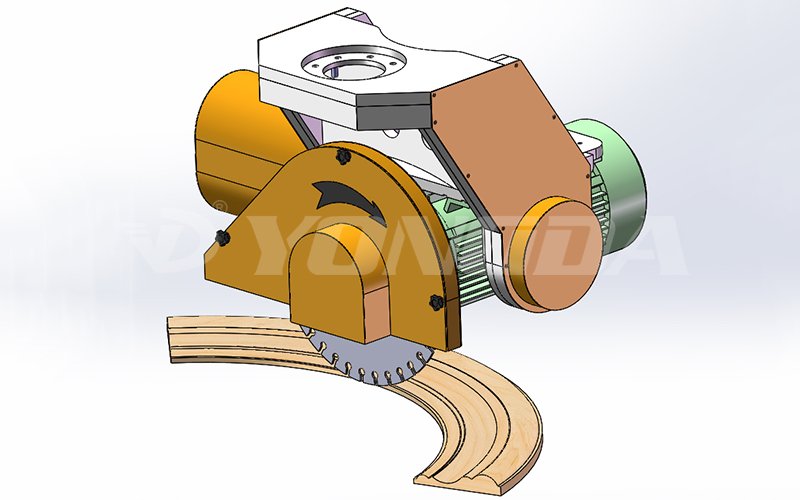

Any angle cutting and polishing

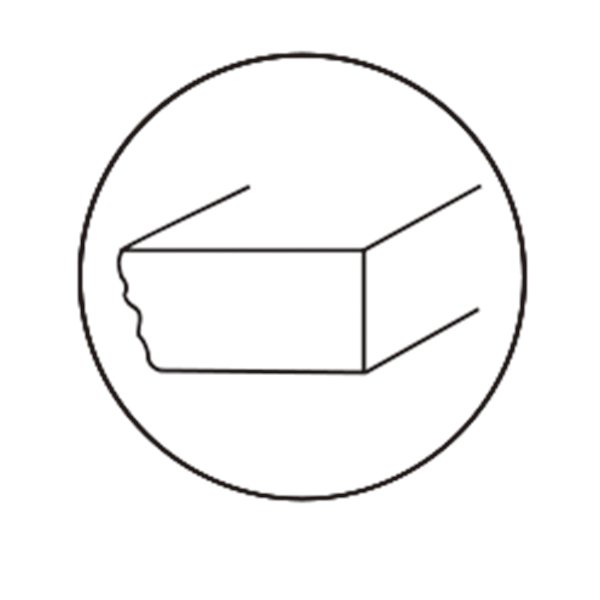

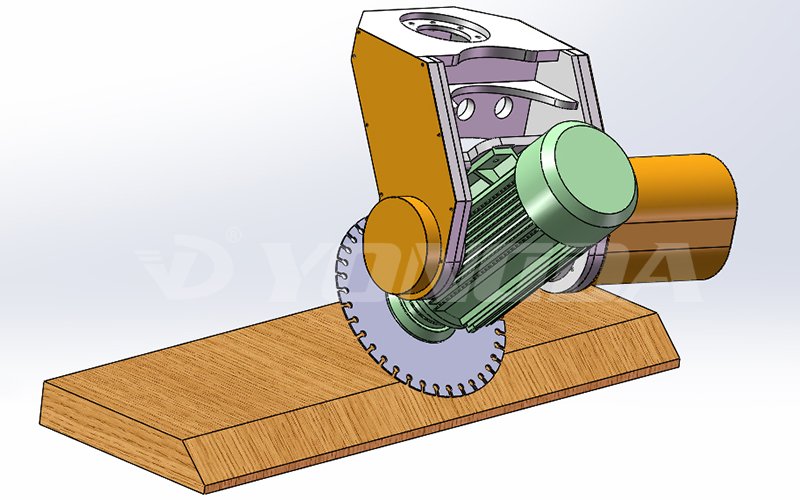

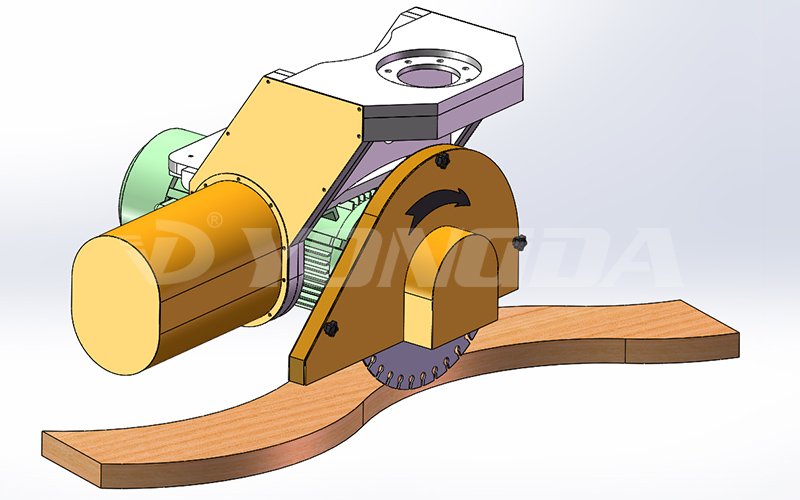

Straight cutting and polishing

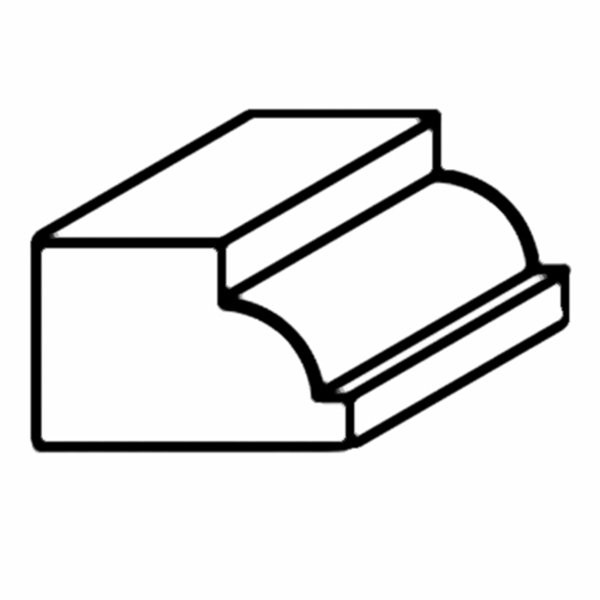

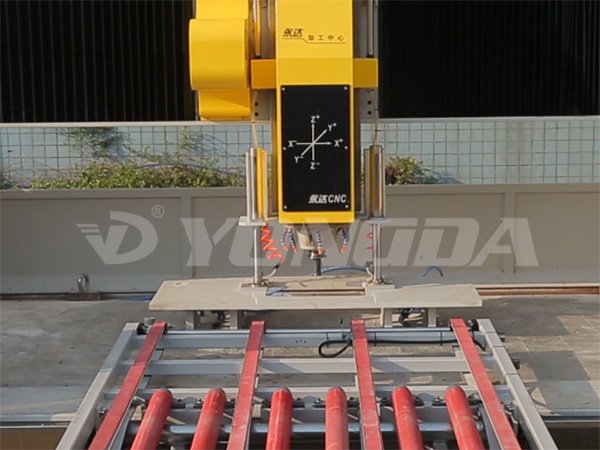

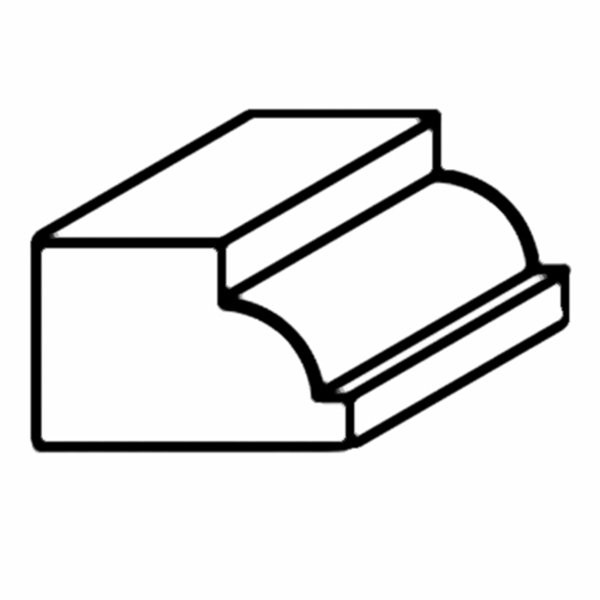

Begonia Edge

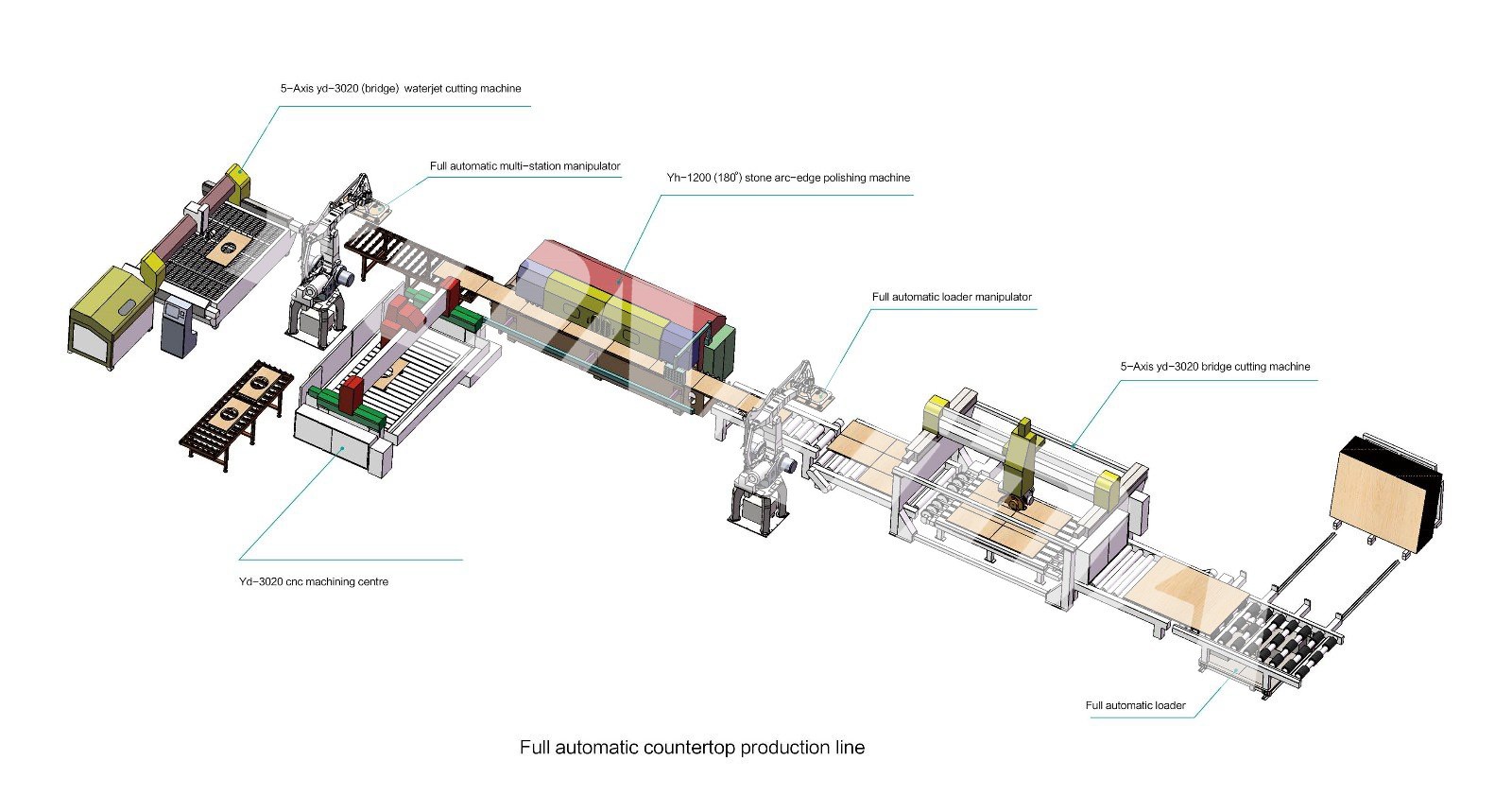

YD-CNC center We have absolute price advantage in North American market.Under the competitive situation,in order to adapt the fierce competition,pursuing high accuracy,high speed,high efficiency modernized processing method,our company has successfully developed and produced CNC processing centre series relying on advanced technical,superior production condition and abundant experience in manufacutering and developing stone processing machinery for many years,Advanced,multi-functional entire computer numerical control processing center,not only can process various materials,such as marble,granite,ceramic,glass,even micro spar and steel,but also can produce various exquisite curve and luxurious model basin board and kitchenware board;As well as various complex bas-relief,2D and 3D artistic letters--"YONGDA"series CNC processing centre,which provides excellent processing method for classical and modern decoration art.

Items | Unit | High allocation type | Public type |

X axis stroke | mm | 3000 | |

Y axis stroke | mm | 1400 | |

Z axis stroke | mm | 350 | |

Max processing thickness of machinable piece | mm | 300 | |

CNC system |

| Italy operating system | Taiwan SYNTEC operating system |

Electronic handwheel |

| EHDW-BA6S-IM | |

Z axis counterweight device |

| High quality nitrogen balance system | |

Wheel-holder spindle motor power | kw | Italy spindle | Chinese spindle (option) |

Automatic tool-change |

| ISO40 | BT40 |

Max diameter of profile polishing wheel | mm | 200 | |

Rotation speed of the tool-holder spindle | r.p.m | 1-12000 | |

Tool-store | nr | 5+5 | |

Water consumption | L/min | 45 | |

Compressed air compressure | Mpa | 0.8 | |

Spindle cooling method |

| Chinese high quality cooler | |

Outer dimension | m×m×m | 5.7×2.25×2.5 | |

Total weight | kg | 4200 | |

Inverter |

| Italy | Taiwan Delta |

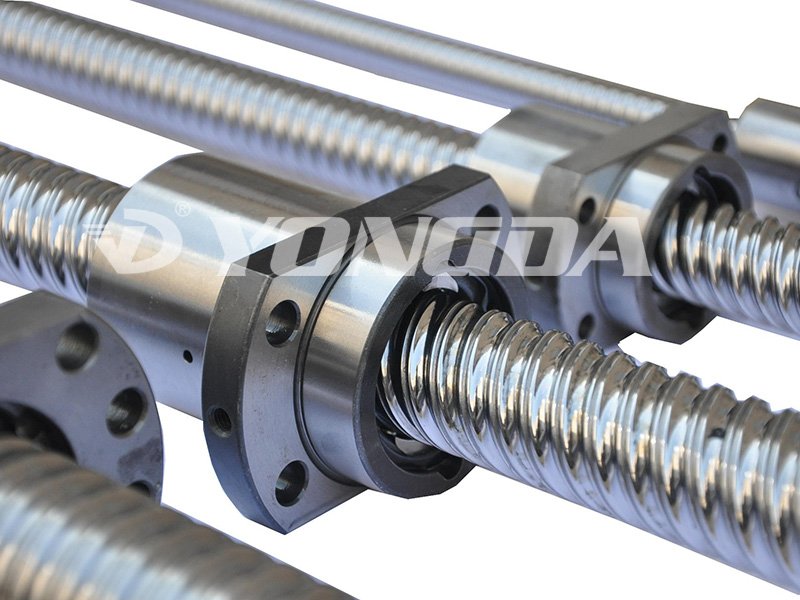

Lubricating system | X,Y axis guide rod apply oil immersed lubrication, Z axis electronic pump automatic lubrication | ||

Digital color photography system | First, the board placed randomly on the workbench is photographed to the working interface, and then the processedgraphics are drawn from the system. The coincidence degree between the processing pattern and the board ismanually adjusted on the system, and the system automatically generates the processing code after the completion.It can be processed without moving the plate and positioning. (for high fit) | ||

engraving

carve

45 degree cutting and polishing

Any angle cutting and polishing

Straight cutting and polishing

Begonia Edge

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts