3-Zone Thermal Shock Test Chamber-LX-80-A

|

|

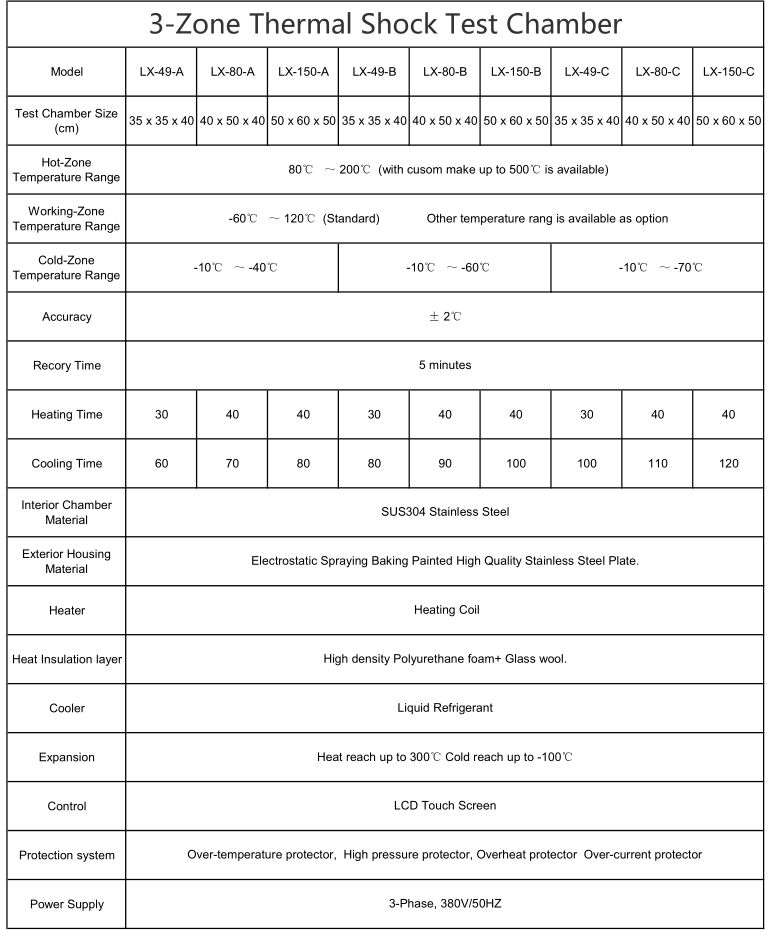

Proudct Parameters

| Product description | 3-Zone Thermal Shock Test Chamber-LX-80-A |

| Model | LX-80-A |

| Appearance overall size(MM) | 950x1600x1050 |

| Actual size of test chamber(MM) | 400x500x400 |

| Working voltage/frequency | 220V/50HZ |

| Power(KW) | 0.96Kw |

| Refrigerant | R404A |

| Cooling way | Air cooling |

| Environment temperature | ≤25℃ |

| Product net weight(kg) | 180Kg |

| Place of origin | Shenzhen, Guangdong, China |

| Packaging | Standard export wooden case |

| Payment terms | PAYPAL or T/T |

| Lead time | Within 15 days |

| Brand | Li Xiang Refrigeration |

| Warranty period | 12 Months |

Product Features

Thermal Shock Test Chamber is used to test the capability of material structure or composite materials to withstand the continuous environmental changes between extremely high temperature and low temperature during a short time, and therefore understand the chemical changes or physical damages caused by expansion from heat and contraction from cold in the shortest possible time. It is applicable to metals, plastic, rubber, auto parts, chemical materials, electronics and other materials. The test results can be used as a reference or basis for product improvement.

This is so called three-zone type thermal shock test chamber.

Sample is placed in the test chamber, more extreme temperature than test temperature can be set in high-temperature chamber and low-temperature chamber. When it comes to low temperature test, cold chamber door open, and low-temperature chamber working together with test chamber.

When converted into high-temperature test, cold chamber door closed, hot chamber door are opened, and test chamber working together with high-temperature chamber.

Conversion of mechanical action (transferring from high temperature to low temperature or low temperature to high temperature) can be completed in less than 1second, and the temperature can be quickly stabilized.

During the whole test, test sample is no need to be moved, and without any human intervention.

Structure characteristics

Interior chamber material: 1.0mm thick mirror SUS304 stainless steel plate.

External housing material: 1.2mm thick electrostatic spraying baking painted high quality stainless steel plate.

Stratosphere structure design: Effectively avoid condensation at the top of the chamber

Heat insulation layer: 100mm thick high density Polyurethane foam+ glass wool.

Sealability: Double heat insulation layer, effectively insulate the heat exchange inside and outside the chamber.

Observation window: Three layers of vacuum glass, easy to observe the sample test.

Illumination design: High brightness window light for easy observation of testing samples.

Machine pulley: Easy to move (adjust position) and match with strong bolts (fixed position).

Control system: Imported Programmable LCD touch screen temperature and humidity controller, visual man-machine interface with bilingual switching function in Chinese and English.

Safety protection system

1. Over-temperature protector

2. Zero-crossing gate fluid power controller

3. Air immolation prevention protector

4. Compressor high pressure protection switch

5. Compressor overheat protection switch

6. Compressor over-current protection switch

7. Fuse free switch

8. Ceramic magnetic fast fuse

9. Line fuse and full sheath terminal

10. Buzzer

Application environment

Allowable application environment temperature range: 0~40℃

Performance guaranteed environment temperature range: 5~35℃

Relative humidity: ≤85%

Atmosphere: 86~106Kpa

No strong vibration around the machine.

No sunlight or other heat sources direct exposure

Drainage pipes must not be raised midway, the housing floor must not have an extreme tilt.

Product Details

Contact

Supplier