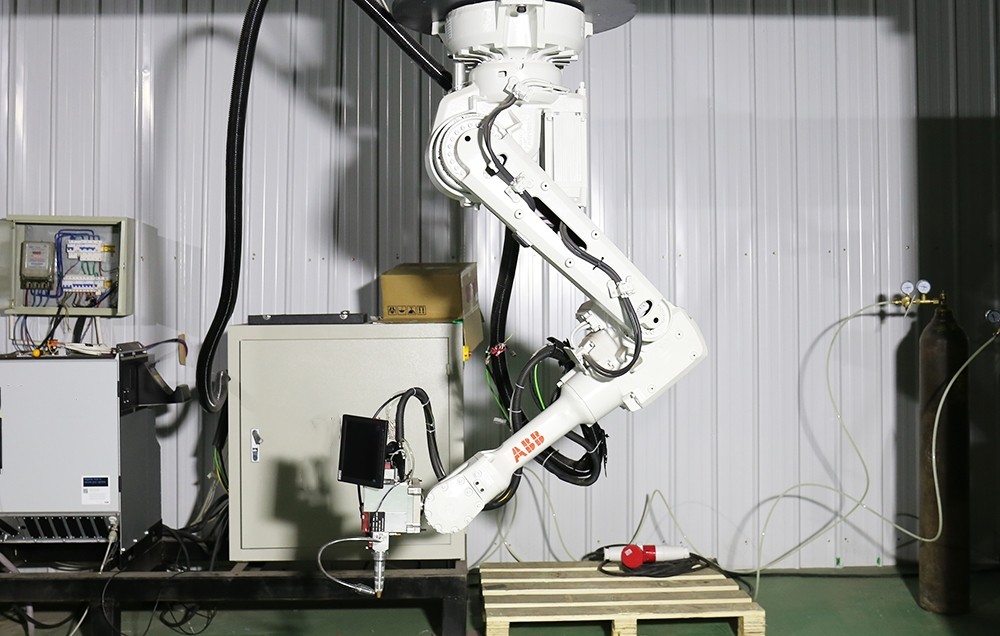

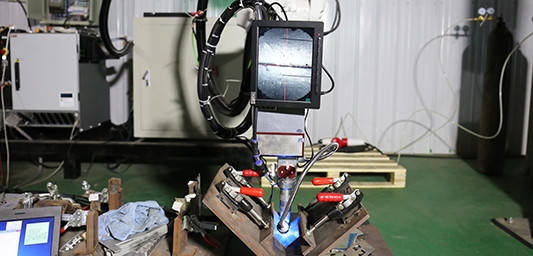

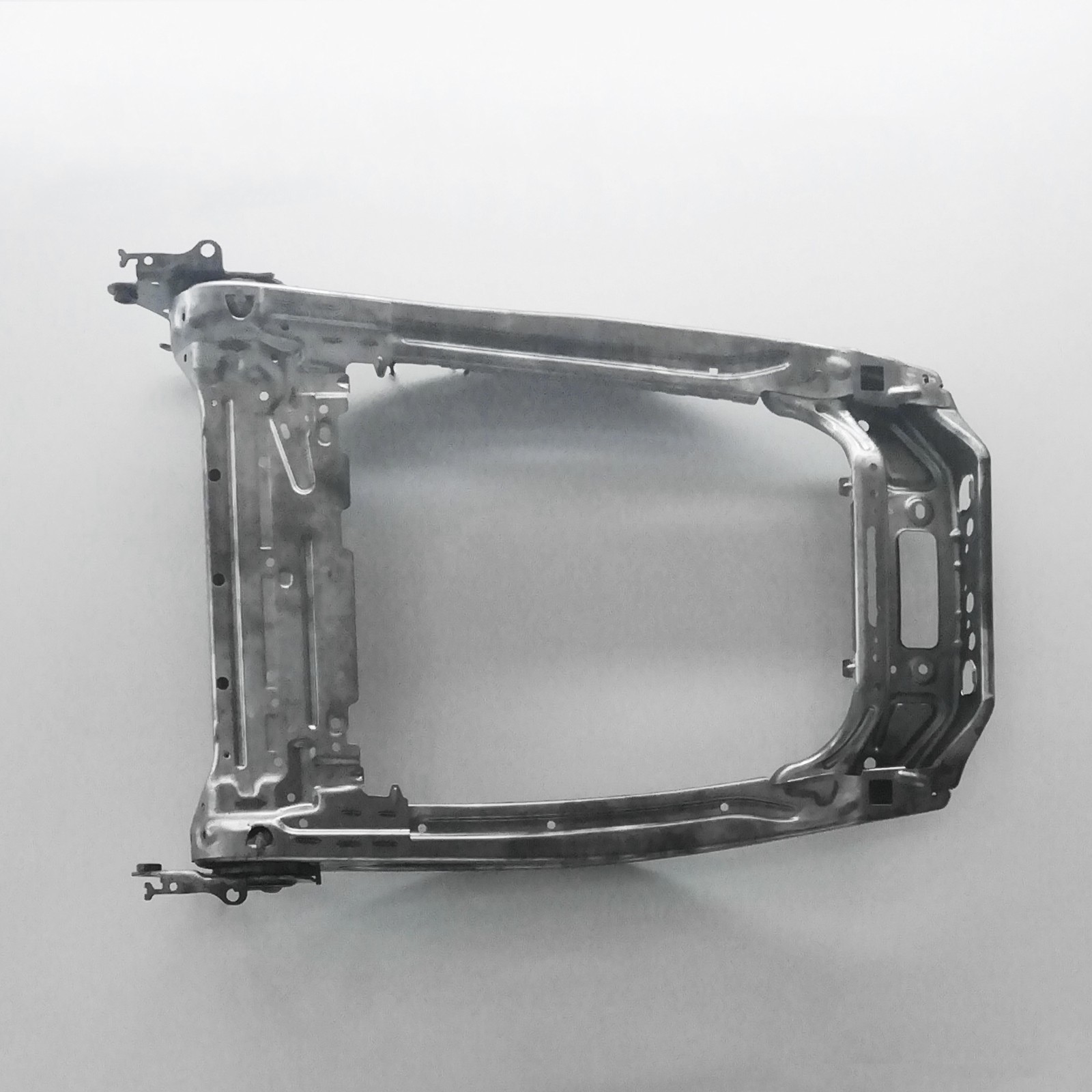

Through independent innovation and technological research and development, the three-dimensional fiber laser welding machine introduced by LASER Intelligent flexibly transmits high-quality laser to the cutting head through gantry fixed upside-down robot or vertical fixed robot base, fiber laser, independently developed PLC integrated control robot, laser and other components to carry out special-shaped welding on three-dimensional parts of automobiles.The thickness of the main production parts of the equipment is 0.4-6mm, and the equipment has the characteristics of good processing stability, high processing efficiency, small machine wear, low use cost and maintenance, simple operation.

3D Robot Fiber Laser Welding Machine

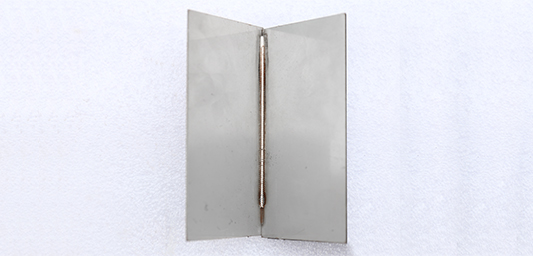

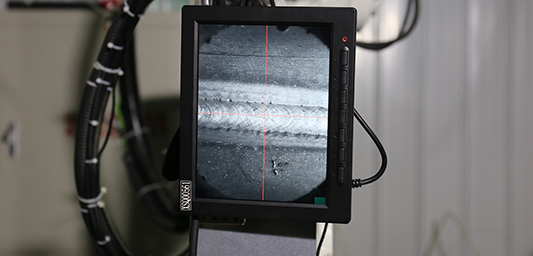

Laser Welding speed is faster,deepper and the deformation is small.

Using laser welding can obtain high quality joint strength and larger depth-to-width ratio, and the welding speed is faster. The heat input can be reduced to the minimum required amount, the metallographic change range in the heat affected zone is small, and the deformation caused by heat conduction is also the lowest.

NarrowThe environmental requirements is low,the welded joint can swing at high speed at will,and forming is beautiful

Can be welded at room temperature or special conditions, welding equipment is simple. For example, if the laser passes through the electromagnetic field, the beam will not shift; the laser can be welded in vacuum, air and a certain gas environment, and can be welded through glass or transparent material of the beam.

High degree of automation and easy operation,micro weldin,

The programming control system, the man-machine interface operation is more clear and convenient, the degree of automation is high, and the human-machine interface is more humanized. after the laser beam is focused, a small light spot can be obtained, and the laser beam can be accurately positioned

Laser focusing,high power density,can weld refractory materials

After laser focusing, the power density is high. when the high power device is welded, the ratio of depth to width can reach 5:1, and the highest can reach 10:1. at the same time, it can weld refractory materials such as titanium, quartz and so on, and can weld heterosexual materials with good results.

Can weld the parts difficult to access

Can be welded with difficult to close parts, and the non-contact and far-interval welding is performed, so that the welding method has great flexibility. In particular, in recent years, optical fiber transmission technology is used in YAG laser processing technology, so that the laser welding technology has been widely promoted and applied.

High processing reliability,strong stability,basic maintenance free

Fiber laser has the characteristics of small volume, low energy consumption, long service life, high stability, maintenance-free, multi-band, green and environmental protection. It has excellent beam quality, stable performance and ultra-high photoelectric conversion efficiency.

Widely used in various manufacturing industries such as aerospace, automobile manufacturing, lamp manufacturing, mold manufacturing, medical equipment, hardware, decoration, kitchenware, metal external processing services, etc.

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts