1280℃

PC Kiln

420x420 Thin Round Bowl Porcelain Bathroom Art Basin 7020

Kedibo have nearly 300 styles of above counter top basin, the square style, the round style, the oval style,and other styles with obvious design characteristic,included. Kedibo can me your all demands about the ceramic basin and will launch many new models as the leader in the basin market. We introduced the advanced kiln equipment from abroad and control the temperature automatically to improve the rate of the high-quality products. Not only improve the production efficiency ,but also the quantity of the basin.

【DESCRIPTION】 Thin Edge Round Porcelain Art Basin

【Certification】CSA for Canada and America

【ITEM】 7020

【Surface/Finish】 Gloosy

【Color】 White (Other color or design avaliabled )

【Shape】 Round Ceramic Basin

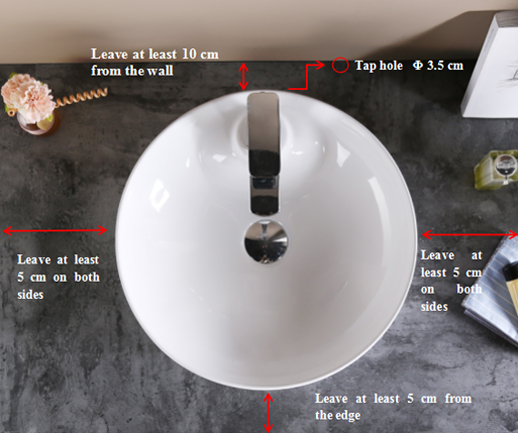

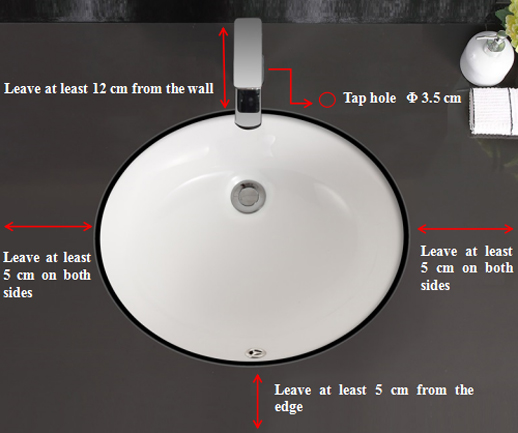

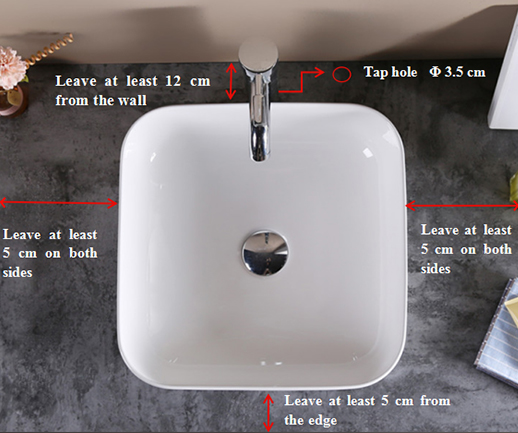

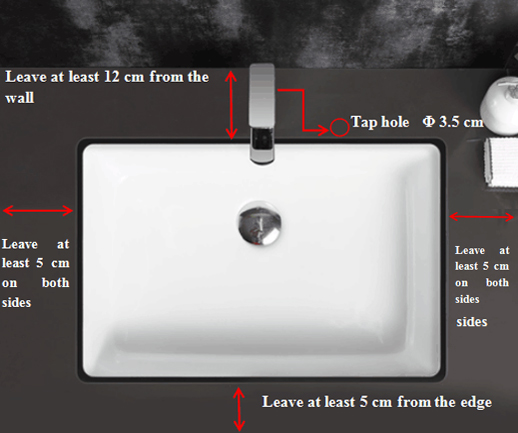

【Installation】 Counter top installation

【Material】 Ceramic

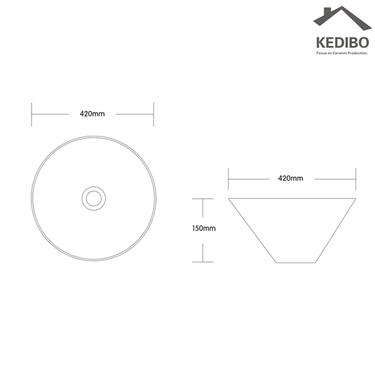

【Product Dimensions】 420*420*150mm

【Water Absorption】 less than 0.3%

【Baking temperature】 1230° C - 1280 ° C

【Glaze thickness】 2 - 3 mm

【Function】 Chemical resistant and Frost resistant, Acid- resistant, Antibacterial, Heat insulation, Wear-resistant

【Usage】 Use in Bathroom

【Packaging】 Standard cartons

Self-cleaning

All in One

10 Years

Since 2010

About Ceramic Basin CSA approved

What importance is:

Round and Thin design, will meet many Asain person demands.

420x420 size small but patical and meet many bathroom size need.

Only a bowl ,simply art basin.

White glaze

Kedibo use the superior glaze to let the surface looks white ,clean and smooth after glazing.

Details management

KEDIBO concentrate the practicability and beauty. We need to do many design and experiments to decide whether the basin need to leave a hole and the install is stable or not and how is the effect of the splash-proof during the process from design to production.

Perfect lines

Each basin in KEDIBO need to conduct two careful working procedure by artificial process then the products will conduct the strict inspection by QC to ensure that the basin is perfect when arrive to the client.

AFTER SALE SERVICE

We have a big team for your after sale service

CONSULTATION

We offer professional consulation for your reference

OEM SERVICE

We have professional OEM serive for personalized customization

MIXED MODEL

We accept mixed models for your requirement.

SHIPPMENT

We offer professional shippment process to all over the world.

◪Look at the appearance-

For a ceramic basin , first of all reflected in the appearance is color and the color should be pure, shiny and evenly distributed. Second, the shape. The basin should have the even line,flat and smooth surface , sleek angle and average straight side.

◪Look for the flaw

A good ceramic basin, the overall heat deflection will not proceed 1/4 in/ft(6 mm/m), and the wall basin heat deflection will not proceed 1/8 in(3 mm), the utilized location, stain,spot and pinprick don’t separate or just less than two;Inside the basin edge and in front of the hemlines,spot don’t separate or the total number less than 4;The lateral side ,spot,pinprick and air bladder ,no more than three on either side and don’t occur separation or total number less than 4. The trifling crack, no gloss surface , eggshell finished , crack, de-glazed, heat crack or obvious spot is recognized as the unqualified products.

◪Touch the glazed position

The following are the positions that need to be glazed for a good basin

A) Back of the basin which touch directly with the wall

B) The back of overflow tube

C) The bottom of the water outlet where bulges

D) The bottom of the basin where shrinks

E) The back of the foot and the base

F)The side of the countertop

◪Do the experiment base on data

The average of the water absorption rate of a good ceramic basin should be lower than 0.5%, but we can’t know the rate when we choose basin. You can do other experiment if you have the overflow equipment. The overflow should have a flow of at least 2.2 gpm (8.3 L/min).From the water into the overflow hole, until the water spill its overflow level, the duration should be no less than 5 minutes.

Square above counter basin

Square under counter basin

Undercounter round basin

Round table top

1.High Quality Clay

2.Slip Casting

3.Demould

4.Air Drying

5.Detail Check

6.Handmade Polish

7.Glazing

8.Detail processing

9.Final Detail Process

10.Computer Kiln

11.Stock

12.Test before package

Contact

Supplier

Aluminum Composite Panels

Balustrades & Handrails

Bathroom

Boards

Building Glass

Ceilings

Countertops,Vanity Tops & Table Tops

Curtain Walls & Accessories

Decorative Films

Door & Window Accessories

Doors & Windows

Flooring & Accessories

Formwork

HVAC Systems & Parts

Kitchen

Ladders & Scaffoldings

Masonry Materials

Metal Building Materials

Mosaics

Plastic Building Materials

Quarry Stone & Slabs

Real Estate

Stairs & Stair Parts

Tiles & Accessories

Door, Window & Accessories

Stone