45 inch/ 49 inch /55 inch/ 60 inch/ 65 inch TV LCD freezer separator machine

|

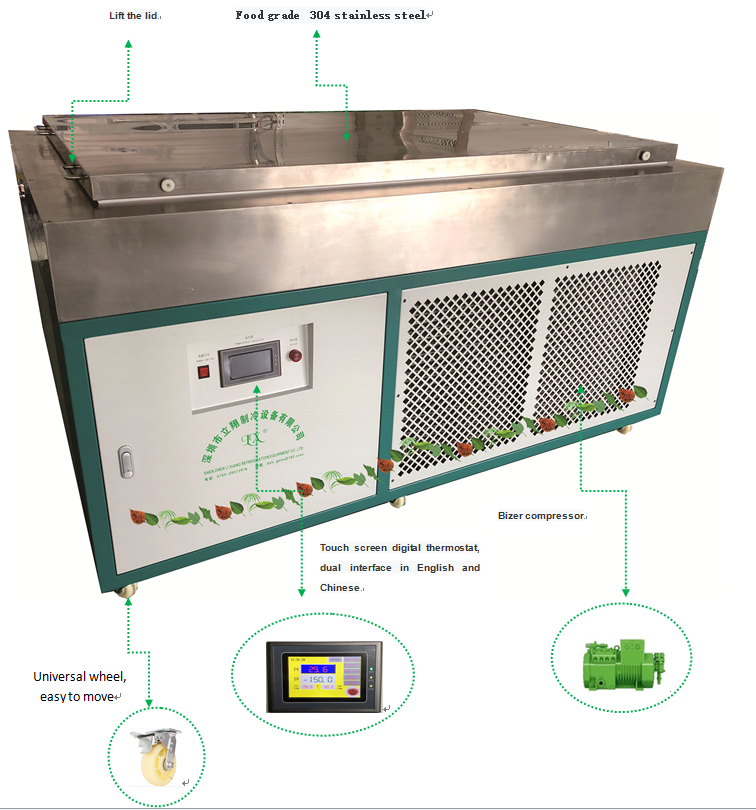

Large-sized TV LCD frozen separator machine, LCD/OLED freezing separator with minus 150/160 degrees, LCD/OLED freezer separator, Large size LCD freezing separator, TV screen freezer separation, Advertisement screen freezer separator, Large TV screen freezing separator, TV screen repair machine, Large LCD screen maintenance machine, Ultra-low temperature refrigerator, Curved TV screen freezer separator, 21 inch freezer separator, 27 inch freezer separator, 32 inch freezer separator, 35 inch freezer separator, 40 inch freezer separator, 45 inch freezer separator, 49 inch freezer separator, 55 inch freezer separator, 60 inch freezer separator, 65 inch freezer separator, 70 inch freezer separator, 75 inch freezer separator, 77 inch freezer separator, 86 inch freezer separator, 98 inch freezer separator, 110 inch freezer separator

Product Pamameters

| Product description | Large-sized TV LCD frozen separator machine |

| Model | LXPB-65INCH |

| Appearance overallsize(MM) | 1955x1280x1050 |

| Actual size of frozen(MM) | 1655x980x80 |

| Working voltage/frequency | 380V/50HZ, 220V/60HZ |

| Power(KW) | 8Kw |

| Cooling performance | -150℃ |

| No-load Pre-Cooling time (H) | ≤2.5 |

| Refrigerant | Environmental mixed refrigerants |

| Cooling way | Air cooling |

| Environment temperature | ≤25℃ |

| Product net weight(kg) | 410Kg |

| Place of origin | Shenzhen, Guangdong, |

| Packaging | Standard export wooden case |

| Payment terms | PAYPAL or T/T |

| Lead time | Within 30 days |

| Brand | Li Xiang Refrigeration |

| Warranty period | 12 Months |

PRODUCT FEATURES

This machine is a style of large-sized ultra–low temperature frozen separator

machine, independently developed based on the working principle of mobile

phone LCD frozen separator machine according to users’ actual requests.

This machine can be used not only in the field of large-sized planar TV LCD

screen separation field, but also in the large-sized curved TV LCD screen

separation field.

The lowest temperature of the unit can reach up to -150℃ without using liquid

Nitrogen as refrigerant. It is widely used to separate out glass, TP, backlight,

OCA, LOCA, bracket from various damaged large-size TV LCD modules.

It is really a good helper for the large-size LCD screen reparation, rework,

refurbishment, recycling industry. Our machines have the following characteristics:

1.) Ease of operation, one-button start, high precision intelligent temperature control system, rapidly reach to the preset temperature.

2.) Imported advanced refrigeration compressor and accessories, can run continuously for 24hours, more stable refrigeration performance.

3.) Equipped with double sealing treatment top opening door and super thick thermal insulation layer box body, excellent thermal insulation performance, effectively reduce the loss of cooling capacity and greatly ensure the working temperature, energy saving, easy to operate.

4.) Safety electricity protection system equipped with ground wire, over heat protection, short circut protection, over current protection, high & low voltage protection, reverse phase lack protection etc. Greatly ensure users’ safety.

5.) Easy to operate, can provide operation instruction, pictures and vedios for users.

6.) Compared with heater vacuum separator, ultra-low temperature frozen lcd separator can help you easily solve your headche about bulk volume separating workload and edge screen separating, it can also peel off a lot of OCA, LOCA glue except for SCA glue.

7.) Both OCA and LOCA full lamination process TV LCD screens can be easily separated by means of ultra low temperature freezing method, while the TV LCD screen with SCA full lamination process can hardly be separated even if put it into liquid Nitrogen.

8.) The large-sized TV LCD screen with OCA full lamination process can be separated at about 110℃, the large-sized TV LCD screen with LOCA full lamination process can be separated at about 125℃.

With the strong growth of the consumer market, large-szied LCD TV is a trend in the future, really one-time investment in this kind of machine, long-term profit.

Below is the URL of youtube video link for your reference:

https://www.youtube.com/channel/UCpXgF19dgOMtxk4wz49-yBw

Operation Instructions:

1.) For serious crushed glass, please stick a tape on glass for safety and good for machine.

2.) Please make sure the operator wears gloves in case of danger.

3.) Before using, it will take the machine around 55~60 minutes to cool to a default working temperature.

4.) Place the TV LCD screen on the frozen plate.

5.) Freezing time from 30 minutes to 35 minutes depends on different full lamination processes TV LCD screens.

6.) For 1 piece of large-sized TV LCD module with 4mm thick glass, it can be completely separated after freezing for about 30 minutes with our machine.

7.) For 1 piece of large-sized TV LCD module with 1mm thick glass, it can be completely separated after freezing for about 15 minutes with our machine.

8.) If put 2 pieces of large-sized TV LCD modules with 4mm thick glass in our machine at the same time, these 2 LCD modules can be completely separated after freezing for not more than 45 minutes.

9.) If put 2 pieces of large-sized TV LCD modules with 1mm thick glass in our machine at the same time, these 2 LCD modules can be completely separated after freezing for not more than 25 minutes.

10.) If put 3 pieces of large-sized TV LCD modules with 4mm thick glass in our machine at the same time, these 3 LCD modules can be completely separated after freezing for not more than 60 minutes.

Note: The maximum capacity of our machine is to separate 3 pieces of large-sized TV LCD modules with 4 mm thick glass at a time.

11.) If put 3 pieces of large-sized TV LCD modules with 1mm thick glass in our machine at the same time, these 3 LCD modules can be completely separated after freezing for not more than 45 minutes.

12.) The maximum capacity of our machine is to separate 6 pieces of large-sized TV LCD modules with 1mm thick glass at a time. The corresponding freezing time will be not more than 60 minutes.

Remarks: For each piece of large-sized TV LCD module, the corresponding separating time will be not more than1 minute. The LCD module separating efficiency will be greatly improved if users can properly operate the separator machine.

The above results are our on-site experimental data and for user reference only.

13.) Separate out TV LCD screen with some auxiliary tools.

Notice:

1.) It is much easier to separate out the bracket and other components after freezing processing. Please pay attention to the backlight water inlet.

2.) After separating the TV LCD screen, pay attention to the water treatment and temperature recovery.

3.) When separating the curved TV LCD screen, the separation risk caused by the temperature difference between 2 sides of the curved surface

screen. Please pay more attention to this point.

4.) After TV LCD separation, please put the glue side upward to avoid sticking on the article surface after the temperature return to the normal.

Product Application

|

|

|

|

| Planar TV LCD screen frozen separation process | Curved TV LCD screen frozen separation process | ||

Product Details

Imported high precision microcomputer temperature controller, precise temperature control + Visual man-machine interface with bilingual

switching function in Chinese and English.

Contact

Supplier