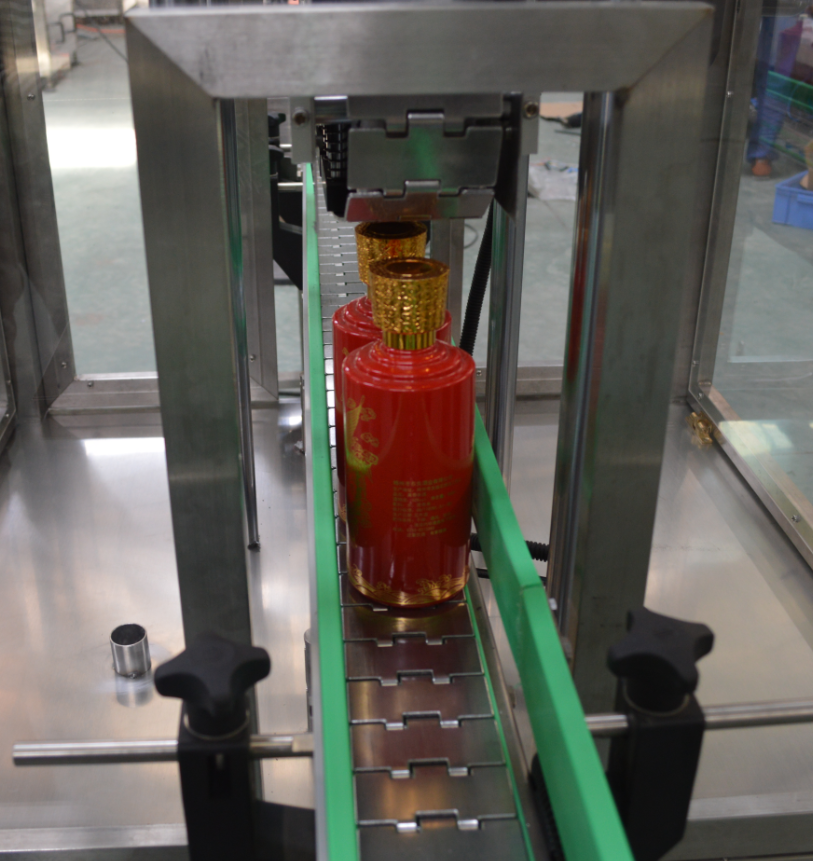

Alcohol bottle washing and drying filling capping code labeling production line

Alcohol bottle washing and drying filling capping code labeling production line

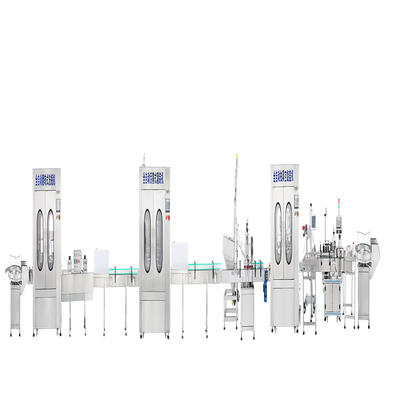

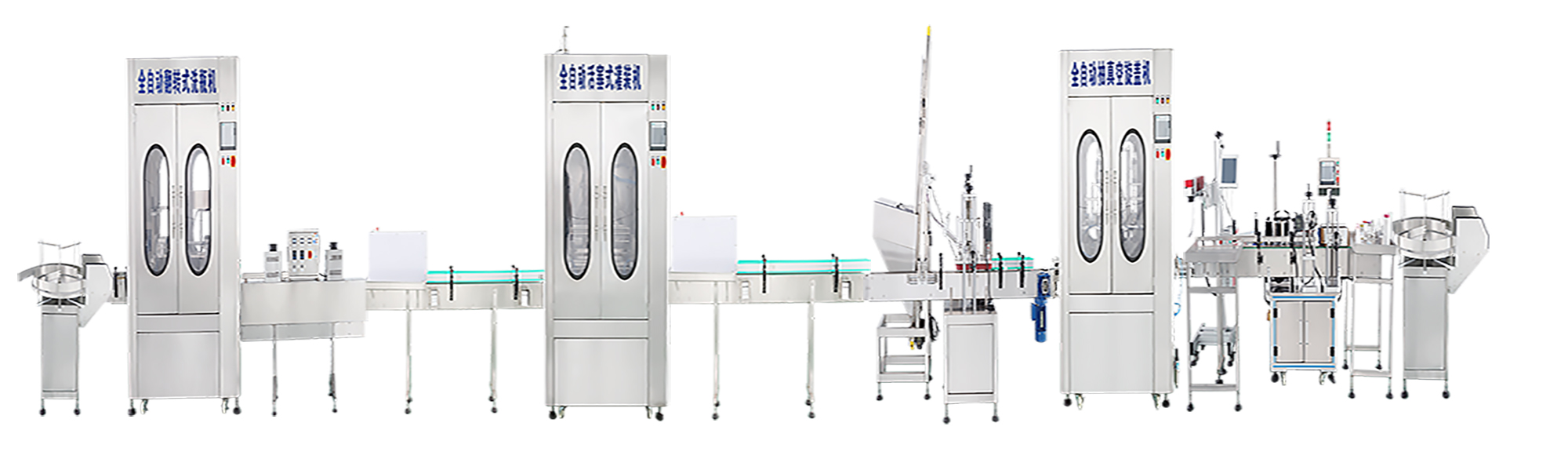

1. Fully automatic production line process: manually put the bottle on the delivery bottle turntable - automatic bottle washing - automatic high temperature drying sterilization - manual light inspection - automatic filling - automatic cover under cover - automatic capping - automatic coding - automatic Labeling - manual bottle collection.

2. This line uses flip-type washing bottle, high-pressure washing bottle.

3.Filling machine adopts servo-driven piston quantitative filling, no leakage, no pollution, simple maintenance, high filling accuracy and stable filling.

4. The screw cap is vacuum-powered with an oil-free vacuum pump, which has high vacuum and easy adjustment of equipment.

5.The coding machine is laser coded, environmentally friendly, the production date will never fade, and the maintenance is simple.

6. The labeling machine adopts servo motor and imported electric eye induction, and the marking is accurate, the labeling precision is high, and the flatness is not wrinkled.

7.All machines of whole line are made of food grade stainless steel, which is convenient for cleaning and disinfecting, and meets the national regulations and requirements for food machinery and food hygiene.

8.The machine use plexiglass cover. It can prevent impurities entering the filling material it is safe and hygienic.

| Applicable bottle width | customized according to customer's products |

| Applicable bottle height | can be customized according to customer's products |

| Filling capacity | 30-300ml (can be ordered as needed) |

| Number of filling heads | customized according to production requirements |

| Filling accuracy | ±1% (equal capacity filling) |

| Production speed | customized according to production requirements |

| Air pressure | 0.6-0.8Mpa |

| Air consumption | 200 l / min |

| Power supply | 380V/50HZ, three-phase five-wire system |

| Whole line power | 23KW |

Bottle feeder

Bottle washer

Dryer

Filling machine

Pressing cover machine

Labeling machine

Q: Are you a factory?

A: Yes, we have a factory in Guangzhou. Welcome to visit our factory.

Q:What is the MOQ?

A:Our MOQ is 1 set and the machine according to your requirements.

Q: Can I customize my logo or package?

A: Yes, happy to accept it. Our factory welcome all OEM&ODM orders!

Q: What is your payment term?

A:There are T/T,L/C.

Q:How to maintain the machine?

A:There are two ways. The first is our engineer will guide by videos. The second is our staffs will go to your country and maintain the machine.(But the tickets and Accommodation charge under your responsibility. And Everyone earns one hundred dollars a day from the starting point )

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts