alumina refractory product for furnace burner, Burner refractory brick

alumina refractory product for furnace burner, Burner refractory brick

Product Description

The burner brick is also called burner, is the industrial fuel furnace with the combustion device commonly known as, can be understood as the "fire nozzle" abbreviation.Usually refers to the combustion device body part, there are fuel inlet, air inlet and jet hole, play a distribution of fuel and combustion air and in a certain way after the role of combustion.

There are different materials for burner block, including chromium corundum, corundum mullite, high aluminum mullite, clay, silicon carbide and so on, to satisfying the requirements of different use temperatures.

Sized or shape: Customized according to customer's requirements or drawings

The functions of the burner brick are:

1) heat the fuel in the burner block to the ignition temperature to facilitate ignition and rapid combustion.

2) maintain a certain high temperature in the burner brick to stabilize the combustion process and avoid pulsation or combustion interruption.

3) organize flame shape to meet the requirements of heating process.

4) mix the fuel and air further.

Technical Data

| Item | Corundum | Sic | High aluminum | Mullite | Cordierite mullite |

| Bulk Density | 2.6g/cm3 | 2.5g/cm3 | 2.4g/cm3 | 2.4g/cm3 | 2.3g/cm3 |

| Cold Compression Strength | 55 MPa | 60 MPa | 45 MPa | 50 MPa | 35 MPa |

| Linear Change On Reheating | 1650°C×6h | 1700°C×6h | 1450°C×6h | 1550°C×6h | 1450°C×6h |

| ≤0.5% | ≤0.4% | ≤0.5% | ≤0.5% | ≤0.5% | |

| Apparent Porosity | 15% | 15% | 19% | 19% | 20% |

| AI2O3 | ≥90% | - | ≥65% | ≥60% | ≥40% |

| SiC | - | ≥85% | - | - | - |

| MgO | - | - | - | - | ≥8% |

| Fe2O3 | ≤0.5% | ≤0.7% | ≤1.2% | ≤0.7% | ≤0.7% |

| Max. Use Temp. | 1600°C | 1600°C | 1400°C | 1500°C | 1400°C |

Features

high compressive strength, good thermal shock stability, high softening temperature under load.Erosion resistance, high wear resistance, anti - stripping.After sintering, the shrinkage rate is low and the service life is 2-3 times of the unfired brick.

Product Display

Application

The burner blocks are suitable for all kinds of industrial furnaces and heat accumulating type heating kilns.

Packaging and shipping

Package:packed on wooden pallet and then polyethylene film is placed over it,finally the package is tied up with steel strips or as your request.

Delivery:15 days after the receipt of your confirmed purchase order

Quality Assurance

Lite Refractory is committed to high quality standards for all its products and services. With its thirst on State of the art technology at every level and a wide range of products, Lite Refractory can provide ideal solutions for the stringent requirement of the customer. Backed by decade of experience in different industries, and close association with customers,Lite Refractory will always bring new products which will give better life and value to the user.

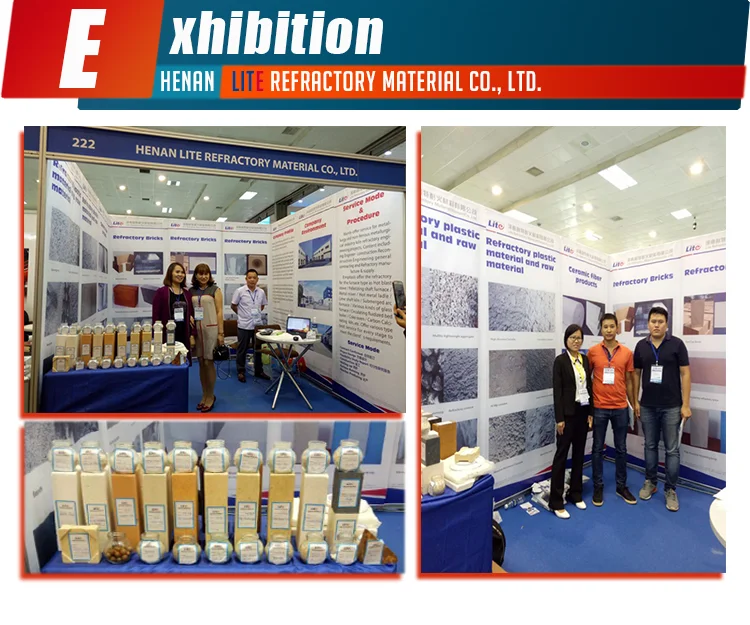

Henan Lite Refractory Material Co., Ltd is located in Zhengzhou Henan province,which is one of the main refractory production bases in China.

Pengfei Zhang the manager of our company,has been engaged in refractory material industry for more than 15 years.In the technological team there are more than 10 senior designers and engineers,more than 20 technicians.

Contact

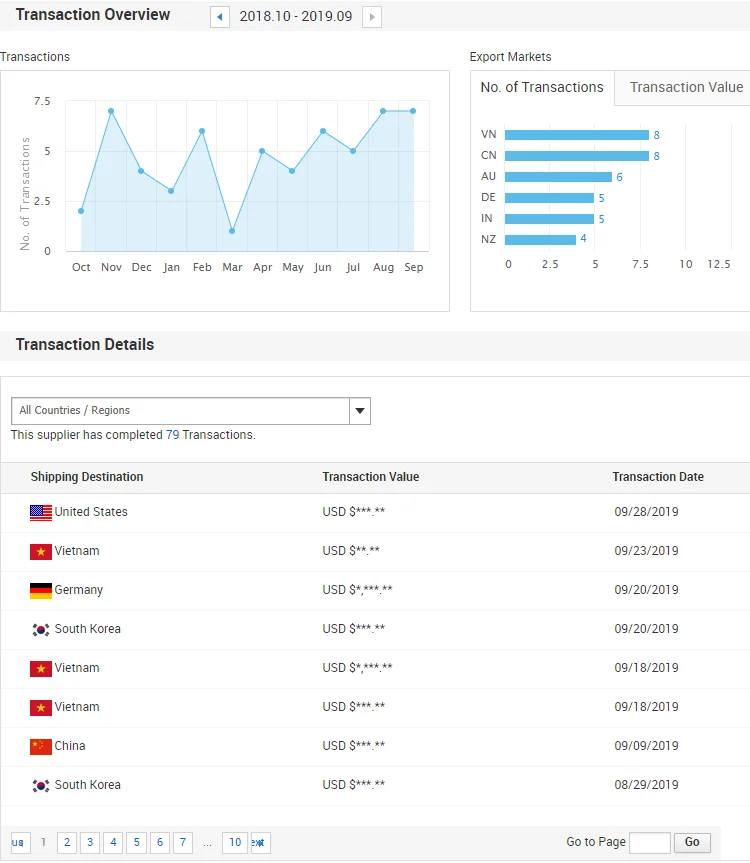

Supplier