1.2SA15201H shoes leather |

Basic Information: |

|---|---|

|

Usage: shoes,bag,sofa,upholstery material |

|

|

Base: four way stretch |

|

|

Thickness: 1.2mm |

|

|

Color: accept customization |

|

|

|

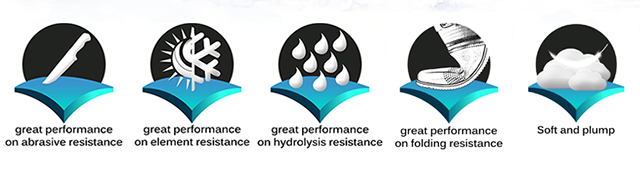

| Prominent Advantages: |

1.2SA15201H shoes leather |

|

No DMF,MEK,toluence and other harmful |

|

|

Easy to clean ,breathable waterproof, flame retardant, anti-bacterial |

|

|

Weathering,aging and wearing resistance, |

|

|

high peel strength, high fracture strength, |

|

|

Abrasion resistance: even being scraped by keys or scissors, our products would not be damaged. |

|

|

No peculiar smell. |

|

|

|

|

|

|

|

|

|

|

Prominent advantage |

|

Anti-hydrolysis for 6-25 years |

|

Fire retardant(pass BS-5852&CA117&FMVSS302 standard) |

|

Pass VDA 270 & DIN 75201 & DBL 8585 standards |

|

zero sovlents(harmful substances)is applied during production |

|

Difference with normal PU(PU layer+fabric base-picture). |

|

Physical & Pchemical performance |

| No. | Test Item | Unit |

Industry Standard |

Our company standard | |||

|---|---|---|---|---|---|---|---|

| 1 | Tensile load | Warp | N | >=250 | >=250 | ||

| 2 | Weft | >=100 | >=300 | ||||

| 3 | Elongation at break | Warp | % | >=100 | >=120 | ||

| 4 | Weft | >=200 | >=200 | ||||

| 5 | Tearing strength | Warp | N | >=25 | >=25 | ||

| 6 | Weft | >=18 | >=25 | ||||

| 7 | Folding resistance | 23℃ 100000times | Warp | / | No crack on surface | No crack on surface | |

| Weft | |||||||

| 8 | 23℃ 100000times | Warp | / | ||||

| Weft | |||||||

| 9 | Peeling strength | N | >=20 | >=25 | |||

| 10 | Surface color fastness | Grade | >=4 | >=4 | |||

| 11 | Blocking resistance | Grade | >=4 | >=4 | |||

| 12 | Cold telorance | / | No crack on surface | No crack on surface | |||

| 13 | Bursting strength | MPa | >=1.2 | >=1.2 | |||

| 14 | Color inhibition | Grade | >=4 | >=4 | |||

|

Chemical Performance |

| No. | Test Item | Test result |

|---|---|---|

| 1 | Benzene | ND(test result: zero) |

| 2 | Toluene(-uol) | ND |

| 3 | Acetone | ND |

| 4 | Butanone(MEK) | ND |

| 5 | Ethyl acetate | ND |

| 6 | Isopropanol | ND |

| 7 | Butyl acetate | ND |

| 8 | Pimelin ketone | ND |

| 9 | Dimethylformamide(DMF) | ND |

| 10 | Phthalate 16P | ND |

| 11 | Cadmium(CD) | ND |

| 12 | Platinum(Pt) | ND |

| 13 | Hydrargyrum(Hg) | ND |

|

Actual applications: |

|

Customer usages feedback |

|

Photo of |

|

Photo of |

|

|

Photo of |

|

Photo of |

|

|

Company info |

|

release paper |

|

stretching area |

|

Joint area |

|

peeling area |

|

unreeling area |

|

QC |

Contact

Supplier