auto PET Stretch 4 cavities 10 liters 5l pet bottle blowing machine

auto PET Stretch 4 cavities 10 liters 5l pet bottle blowing machine

Brief introduction

JND series of automatic stretch blow molding machine is widely used to produce varieties of PET plastic container and package for mineral water, beverage, oil, cosmetic and hot infusion, ect.

This machine use for PET oil bottles.

Features:

1. Linear structure,module designed,P-T-P controlling,easy maintenance.

2. HMI control panel simplified operation.

3. Low noise,stable structure.

4. Drawer mold fixed structure,exchange mold more easy, just need 30 minutes.

5. Semi-closed heating structure,even preform heating,low reject rate.

6. All the steel plate with GB standard,the clamp unit plate and frame both with heating treatment by CNC,which ensure the machine balance and accuracy.

7. All the machine’s doors are detected by the sensors to keep safety.

8. High pressure air recycle system can save about 50-60% high pressure air, which reduces energy consumption.

Main technical standards:

|

Model |

JND-2LB |

|

| Theoretical output(bph) |

1400-1600 |

|

|

Molding |

Clamping force(kgf) |

30000 |

|

Clamping stroke(mm) |

220 |

|

|

Stretching stroke(mm) |

450 |

|

|

bottom stroke(mm) |

50 |

|

|

Cavity distance(mm) |

225 |

|

|

Number of cavity |

2 |

|

|

Container |

Max. Volume(6000ml) |

6 |

|

Max. neck diameter(mm) |

50 |

|

|

Max. bottle diameter(mm) |

195 |

|

|

Max. Height(mm) |

355 |

|

|

Machine |

Size(L×W×H)(mm) |

2400×2150×2500 |

|

Weight(T) |

4 |

|

ShenZhen J&D Drinking Water Equipment Co., Ltd. is China's leading manufacturer of bottling equipment and supply the global market with a complete range of bottling equipment and accessories.

J&D Water can supply the following equipment:

* water dispensers, water filtration systems and all associated equipment required for a bottling factory including bottle blowing, labeling and packaging equipment.

*3000-36000BPH mineral water & pure water processing and filling lines

Wooden case

Engineers available to service machines overseas.

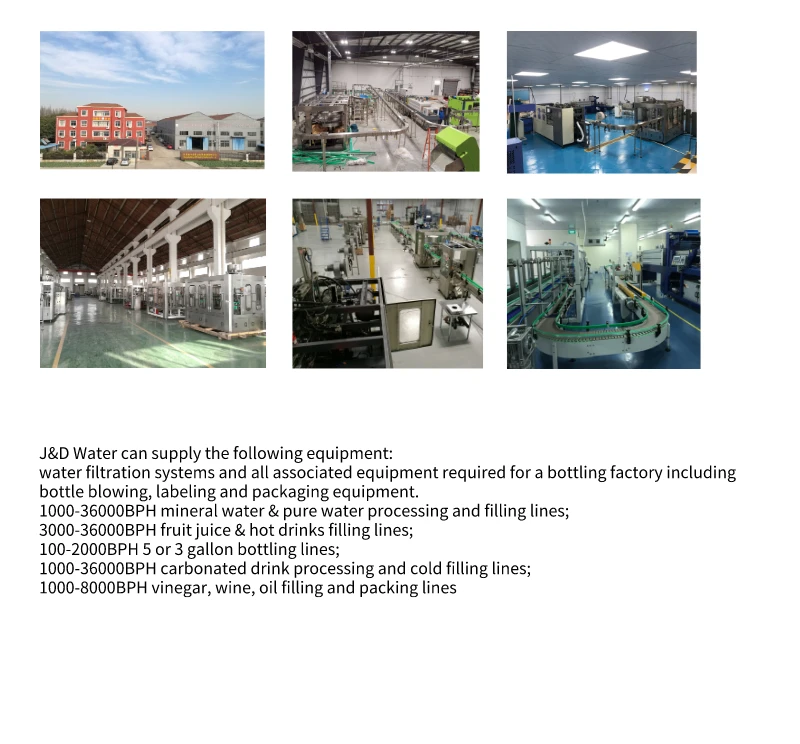

Some project cases

ShenZhen J&D Drinking Water Equipment Co., Ltd. is China’s leading manufacturer of bottling equipment and supply the global market with a complete range of bottling equipment and accessories.

J&D Water with fixed assets of over 80 million $ u.s. and a global turnover of over 500million $u.s. employ 1500 staff in the design, manufacture and sales of their range of bottling equipment. The total manufacturing and administration areaowned by J&D is over 70,000 sq meters.

J&D Water are ISO9001 approved and all of the equipment manufactured by J&D is manufactured to the following standards CE, TUV, GS, ETL, UL, SASO, RoHS and CSA.

J&D Water operates a program of continuous improvement in the design and quality of their equipment and where appropriate utilizes advanced filling technologies from Germany, USA and Italy.

J&D Water can supply the following equipment:

* water dispensers, water filtration systems and all associated equipment required for a bottling factory including bottle blowing, labeling and packaging equipment.

*3000-36000BPH mineral water & pure water processing and filling lines;

*3000-36000BPH fruit juice & hot drinks filling lines;

*100-2000BPH 5 or 3 gallon bottling lines;

*2000-36000BPH carbonated drink processing and cold filling lines;

*1000-8000BPH vinegar, wine, oil filling and packing lines;

* A full range of water treatment equipment.

With world leading technologies and a program of continuous improvement, all the products supplied by J&D Water have gained a good reputation from their global customer base. J&D have exported bottling and associated equipment to theUSA, UK, Ireland, Canada, Australia, Mexico, Russia, Africa, the Middle East area etc for over 10 years. J&D Water can assist with factory layouts and can also provide a full installation and technical back up service.

Anymore information,pls feel free to contact us.

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts