Automatic and Mobile Linear Beverage and Beer Can Filling Machine Equipment System for Sale

Supplier Info.

Company Name: YANTAI TRANO NEW MATERIAL CO.,LTD.

Registration Date:

2004

Country / Region:

shandong / China

City:

yantai

Main Products:

beer keg,beer barrel,kegs of beer

Product Detail

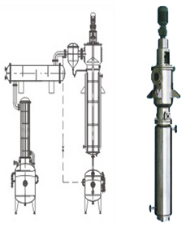

Automatic and Mobile Linear Beverage and Beer Can Filling Machine Equipment System for Sale

Products Description

Canning Line | ||

T R C 4-4 | ||

Filling Head | 4 | |

Speed | 25-30 cans/min | |

Can Size | 330-500ml/customized | |

Purge&Fill Station | Automatic | |

Can Lid Placement | Automatic | |

Seamer Station | Automatic | |

Upgradeable | No | |

Designated Mobile Option | Yes | |

Eurpean CE Option | Yes | |

Net Weight | 285KGS | |

Size | 2290×950×1850 | |

Main Structure

2) During the filling process, the cans cannot lift, valves lifts. Valve lifts controlled by air cylinder not controlled by the ordinary mechanical movements, consequently little wear.

3) Filling machine and sealing machine have the same pitch which makes transportation speed more stable, it hasn't out transition sprocket like small cans filling & sealing machine.

4) Perfect controlling of liquid level in filling tank. It ensures a stable liquid for tank in filling process.

5) Adopt FERRUM's sealing technology, friendly maintenance and management for users. (With the existing imported sealing machines same technology)

6) Complete CIP cleaning channel designed, for easy cleaning equipment.

Details Images

Certifications

Related Products

Packaging and Shipping

Size | Depends on equipment |

Weight | 285KG |

Packaging Details | The normal package is non-fumigated plywood(Size: L*W*H). If container is too tigher, we will use pe film for packing or pack it according to customers special request. |

Our Service

Company information

FAQ

By using this product, the chances of errors will be greatly reduced. This will contribute to the reduction in production costs due to human error. Its shell is water-proof and dust-proof, making it suitable for beverage storing.

People can invest in this product that can increase production efficiency and lower fixed costs such as time cost and labor cost. Its shell is water-proof and dust-proof, making it suitable for beverage storing.

Contact

Supplier

Contact us

Tell us your Buying Requirements

You Might Also Like

Product Groups

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts