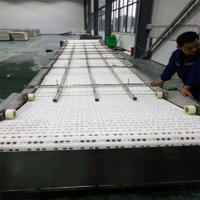

Automatic Empty Can Depalletizing Machine

Applicaiton:

Theautomatic or semiautomatic empty can (bottle) depalletizing machine is mainly suitable for automatically depalletizing three-piece cans, two piece aluminum cans and glass bottles.

The empty cans (bottles) palletized on the pallets will be pushed pile by pile to the conveyor after they are hoisted, and then they will be sent by multiple rows of conveyors or rotary discs to the sliding channel type can washing machine or automatic bottle washing machine.

It can replace the manual can (bottle) arrangement, which has increased production efficiency. It is an indispensable ideal device for middle and large-sized beverage plants.

Main techniacl parameters:

| Production capacity | 200~600 cans/min |

| Applicable can diameter | 52~153mm |

| Applicable can height | 39~170mm |

| Can (bottle) pushing form | automatic or manual can pushing, net belt conveying |

| Can (bottle) discharging form | can discharging changing from multiple rows of conveying belts into single row of conveying belts |

| Hoisting form | automatic/Semi-automatic |

| Power | 4kw |

| Dimensions: | 7.0m×4.0m×3.0m |

| Weight | 2.5T |

Anymore information, pld feel free to contact us, also welcome to visit us.

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts