Automatic Riveting Machine/pneumatic/ for Blind Rivets 2.1mm-6.4mm/Error Prevention/High Speed/RM131

Product Video

Product Advantages

Product Information

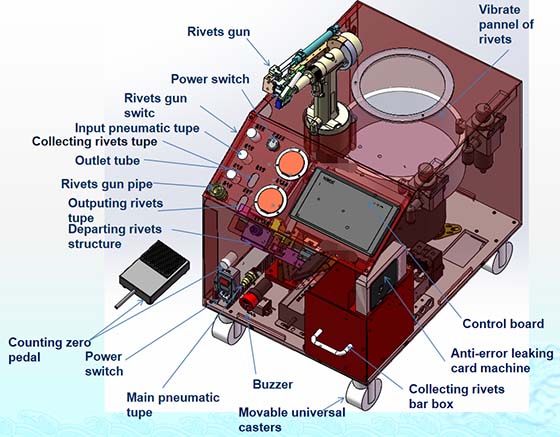

The automatic feeder riveting machine is used for delivering blind rivets automatically with pneumatic rivet guns,which highly improves the efficiency of fastening rivets. It's simple and convenient to operate.It also could help you save labor cost by at least 50%,expand production capacity,prevent missing and errors.At present,it has been applicated for sheet metal industry,home appliance,automobiles,ships,airplanes,etc.

| Model No | RM131 |

| Name | Automatic Riveting Machine |

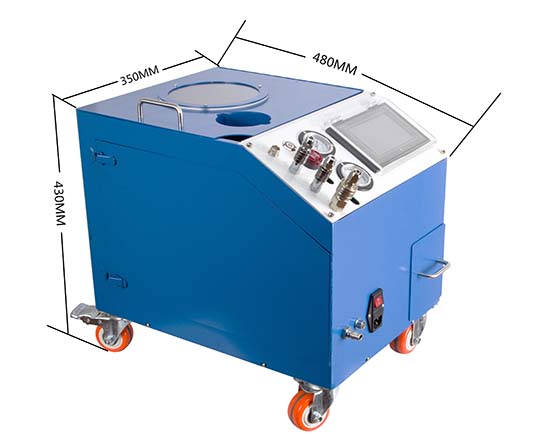

| Color | White and Blue |

| Application | Distributing Rivets Automatically |

| Air pressure | 0.5-0.8Mpa |

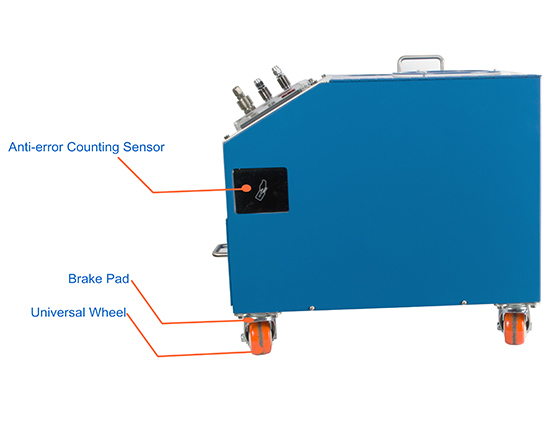

| NET WEIGHT | 40kg |

| Capacity | 2000 Rivets |

| Length | 480mmxWidth:350mmxHeight:430mm |

| After-sales Service Provided | Authorized Agents Provided the service |

Product Details

Product Specification

| Riveting unit weight | 2.3KG |

| Control | Automatic,Electrical |

| Rivets type | Blind rivets |

| Rivets diameter | 2.1-6.4mm |

| Voltage | 110V-240V 50/60Hz 1Phase |

| Driven power | Pneumatic |

| Pneumatic pressure | 2.5-4.5kgf/cm2 |

| Dimensions | 480x350x430mm |

| Net weight | 40kGS |

| Working temperature | +5° / +40° |

| Hoses length | 1.7M |

| Length of supply lines | 2.3M |

| Packing Includes | 1x Automatic Feed Riveting Machine 1x Pneumatic Riveting Gun |

Application Fields

THE APPLICATION FIELD OF OUR PRODUCTS

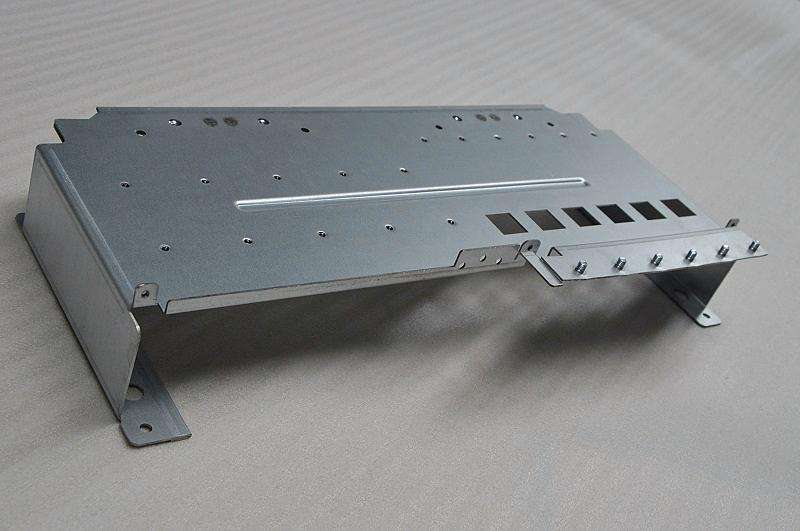

It has been widely used for riveting blind rivets,such as computer terminal case,aluminum alloy cabinet,aluminum case,small appliances,microwave ovens,lighting,automobiles,ships,airplanes,etc.

Normally using the rivets of 3.0MM to 3.2MM

Normally using the rivets of 3.0MM to 3.2MM

Normally using the rivets of 3.0MM to 3.2MM

Normally using the rivets of 4.8MM

Normally using the rivets of 4.8MM

Normally using the rivets of 4.8MM

How to Pack the automatic riveting machine?

No worry about long shipping time by sea.

Make sure the machine safe and in right position.

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts