COMPANY INTRODUCTION

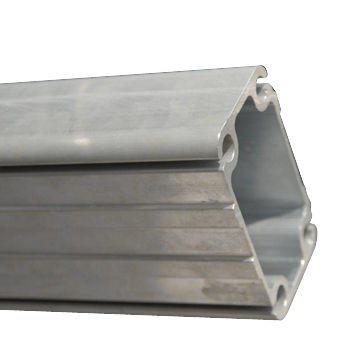

Zhaoqing Aisa Aluminum Factory Company Limited is one of the largest manufactures of extruded aluminum profiles in Aisa. Since its establishment in 1991,the Company is dedicated to the design and manufacturing of advanced high precision extruded aluminum profiles.Through years of effort and perseverance, Aisa Aluminum's product range has expanded from architectural doors,windows and curtain walls to various industrial profiles, aviation,rail transportation,automotive electronics application, communication technology,IT etc., with its products being used all over the world.

Power coating

Brushed

Electrophoresis

Wood Grain

Polished

Mould

Extrusion line

Temper

Anodizing

1.Four anodizing lines, monthly output 1000T.Anodizing thickness is up to 25um.

2.Color choices:Silver,bronze,champagne,titanum,nickel,golden yellow,etc.

3.Standard:DIN, AAMA, AS, CHINA GB.

Powder Coating

1.Two powder coating lines, monthly output 600T. swiss machine GEMA.

2.Powder coating thickness is more than 60um.

AKZO NOBEL INTERPON, NIPPON.

Weather Resistance: more than 10 years.

3.Standards: DIN, AAMA, AS, CHINA GB.

Wood Grain

1.Monthly output 300T.

2.AKZO NOBEL INTERPON D34 & D1010.

3.Italian MENPHIS transfer printing paper.

4.Weather Resistance:5-10 years guarantee.

Polishing & Brushing.

Semi-Automatic PET Bottle Blowing Machine Bottle Making Machine Bottle Moulding Machine

PET Bottle Making Machine is suitable for producing PET plastic containers and bottles in all shapes.

Welcome to our company

Welcome to our exhibition

Welcome to our factory

Free from worry

Any time is OK

Design for you

Packing Details : After routine packaging, plywood is needed to avoid fumigation tray + wrapping film fixation.If the product exceeds the length (more than 2.3 meters), the iron frame + wheel will be loaded into the container.

Delivery Details : Can provide full container and LCL delivery.

Q1: What's the thickness for anodizing? Can you do 15um?

A: Our normal thickness is about 10 um. Yes, we can do 15um and above.

Q2: What color you can do for powder coating? The thickness for powder coat?

A: We can do any color for powder coat as long as you can provide the color sample. Our normally powder coating thickness is 60-80um.

Q3: What color you can do for wood grain?

A: Our most popular colors are Western Red Cedar, Australia Cedar, Jarrah I, Jarrah II, Chestnut, Bush Cherry, Bush Wood, Western Wood, Snow Gum, etc. If you need any other colors, we can do according to the color samples you provide.

Q4: How's the weather resistance for wood grain finish D1010?

A: (1). Powder: Akzo Noble Interpon D1010.

(2). Wood grain film: Italian Menphis.

(3). Standard complied: American AAMA Standard.2603

(4). UV test:1000 hours.

(5). Salt spraying test:1000 hours.

(6). Normal weather: 10 years color guarantee.

Q5: What's your MOQ?

A: Normally speaking, it's 2 tons.

Q6: What's payment terms?

A: Usually by T/T, 30% deposit and the balance paid before shipment.

Q7: What certification do you have? What's your standard?

A: We have ISO certification. Our standard is DIN, AAMA, AS/NZS, China GB.

Q8: What's the delivery time for samples and mass production?

A: (1). 2-3 weeks to open the new moulds and make free samples.

(2). 3-4 weeks after receipt of deposit and confirmation of the order.

Q9: What's the packing way?

A: Commonly we use plastic film and kraft paper, also we can make as per customers' requirements.

Contact me:

Sales manager:

Echo Zhang

Wechat/Whatsapp/Mobile:+8618664544447

Contact

Supplier