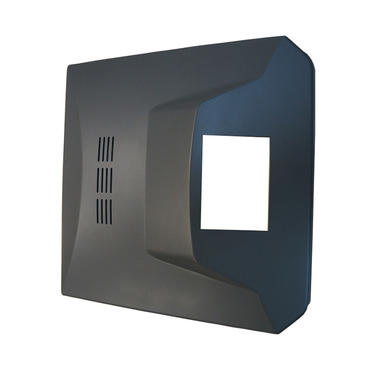

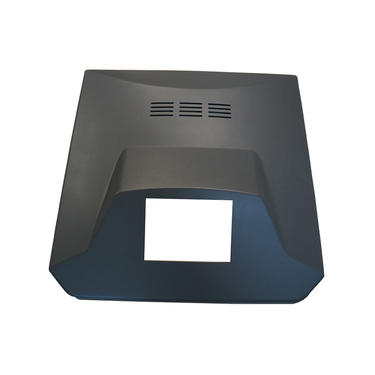

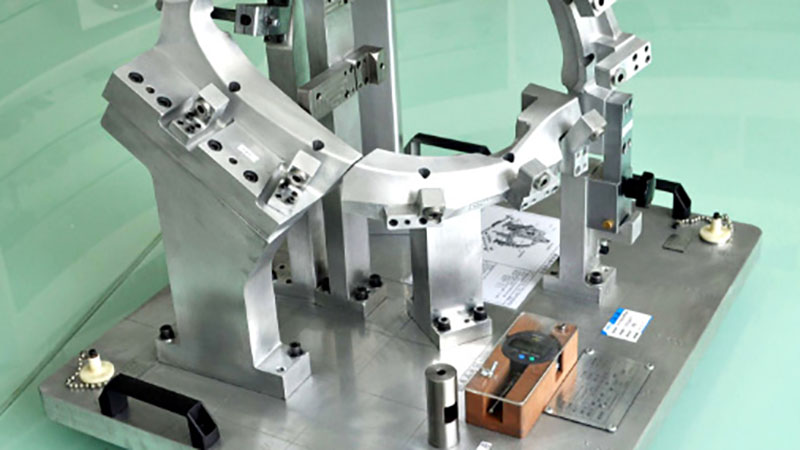

CNC Machining

◪ CNC Machining is an automated process by which a machine processes a computer file to create a highly complex object from plastic or metal.

◪ Regardless if your product is simple or complex, we at Fu Jia can manufacture your desired CNC (Computerized Numerical Control) machined part. Our innovative CNC machining process is made to achieve the best speed and efficiency. This helps us deliver the parts you need to keep your projects when quality, timing, and pricing are critical.

◪ Using our advanced 3, 4 and 5-axis CNC machining centers, our skilled team can produce turned and milled parts with a wide array of plastic and metal materials.