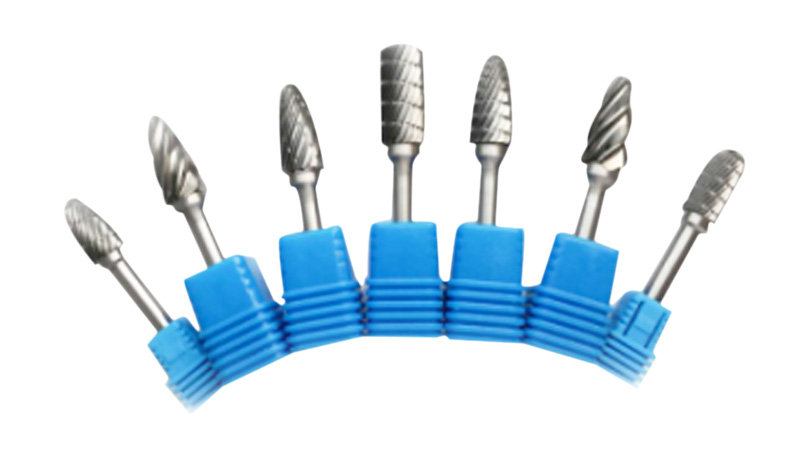

Carbide Burr Bits DIN8032 6mmShank(Flame)

Product Information

Product Specifications

| Carbide Burr DIN8032 6mmShank(Flame) | |

| Modle No. | Description |

| 489-0908 | B 0820, Double cut |

| 489-0912 | B 1230, Double cut |

| 489-0916 | B 1635, Double cut |

Product Description

◪ Material: 1.Working part: Tungsten Carbide YG7(K30);2.Shank: Carbon Steel

◪ Carbide-tipped contact points make it highly durable.

◪ Hardness: ≤HRC65

◪ Standard: Metric sizes are under ISO and Din standard; Inch sizes are under American standard.

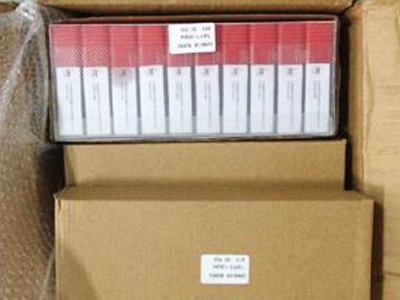

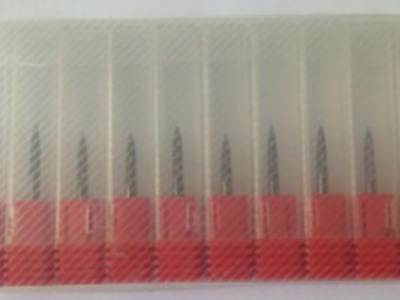

Packing

Individual size:1pc packed in 1 plastic tube and then in good quality carton suitable for export.

Set: packed in plastic box, wooden box

Applications

◪ Widely used in maching iron, steel casting, carbon steel,alloy steel, stainless steel,cooper aluminium,etc.

◪ Machine various kinds of die cavities.

◪ Remove the burrs of the castings, forgings and the welding spatter.

◪ Chamfer the angles,circular bead or flute on the mechanical components.

◪ Chamfer or bur the pipes.

◪ Polish the impeller channel.

◪ Grind the hole to an accurate shape.

Contact

Supplier