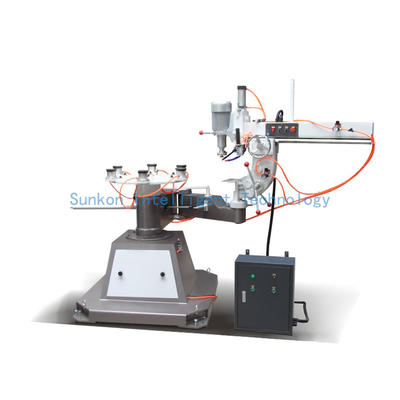

CGSZH1225 High-Speed Smart Double Edging Production Line

This production line consist of two straight line double edgers and one L shape automatic transfer table. Is one of professional production line for rectangular glass chamfering and bottom edging. And especially suitable for architectural glass, windows and doors glass, homeappliances glass and LOW-E glass. Automatically identify and adjust the glass width and thickness, it saves the setting time and spees up the size changing of different glass. Adopting PLC control system. Setting the parameter on the interface to control the processing sidth and speed. High density doubles straight line guide rail and pinion and gear rack structure and control system. It can process the thin glass 3-12mm. It is featured with high edging speed and high transfer efficiency and suitable for industry glass deep-processing. Being connected with other machines, the production efficiency can be improved deeply.

Features:

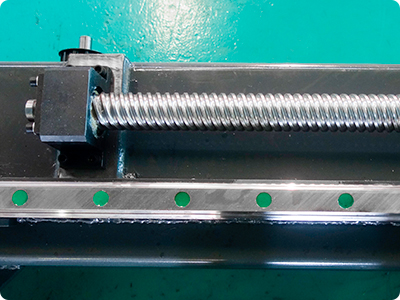

■ Flange adopt double Ball strew and straight line guiding rail, resetting well.

■ Grinding head planker adopt high precision double V guiding rail, running stable, small shaking.

■ Polishing adopt manual and Pneumatic half auto compensate.

■ Upper angle of chamfer adopt ball screw and straight line guiding rail, Accurate positioning.

■ Master drive adopt mechanism frequency conversion speed regulation, main driving axle upper place, easy change belt and maintain.

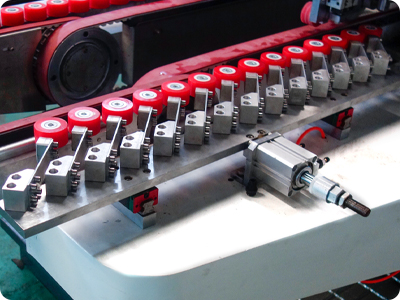

■ Glass transmit adopt annular timing belt and pneumatic locating device, transfer stable, exactly fixed position.

■ Adopt human interface and PLC control system, easy operate

Number of Spindles | 12 motors |

Max. Glass size | 2500 mm |

Min. Glass size | 350 mm |

Glass thickness | 3-12mm |

Max.hemline grinding | 5mm |

Max. Arris grinding | 3mm |

Speed | 1-16m/min |

Working height | 920mm |

Voltage/Frequency | 380V/50HZ |

Compress air | ≥0.6Mpa |

Air blowing rate | 1320 m3/Min |

water pump output volume | 400L/hX2 |

Total power | 49.5 Kw |

The Siemens brand PLC Control, can be operated automatically or manually. The touch screen displays glass thickness, working speed, edge removal and finished meters.

The Schneider brand electronic components

The Schneider brand to ensure the machine runs smoothly and durable for using.

Grinding head Adopt ABB motors, and grinding head pallet adopt enclosed structure, good for dustproof water proof

Ball screw,Linear rail Adopt Taiwan brand

box adopt enclosed structure, good for waterproof

Grinding head pallet adopt automatic oil lubrication

Secondary positioning mechanism

main transmission mechanism,Its bearing good for waterproof, difficult damage and durable for use.

Now contact us for order via this sheet, to get more free spare parts or discount!

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts