China Copper Skived Fin Heat Sink From Lori

| Place of Origin: | Shenzhen, China (Mainland) | OEM: | Yes |

| Process: | Skiving fin | Temper: | T3-T8 |

| Material: | Copper | Shape: | Square |

| Packing: | Paper carton with wooden pallet | Brand Name: | LORI |

| Application: | LED Lighting | Certificate: | ISO 9001:2015,ISO 14001:2015 |

| Model Number: | LR0002 | Tolerance: | 0.05 mm |

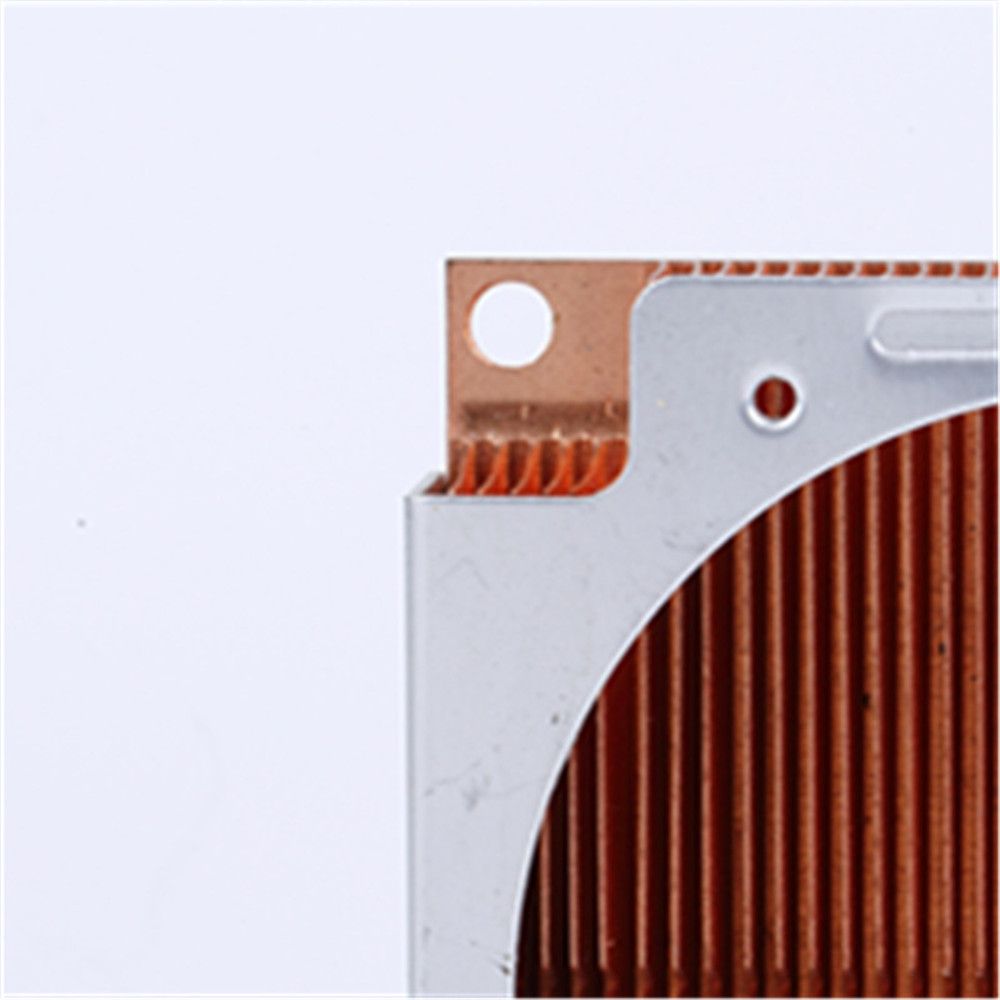

| Finish: | Pssivating | Fin thickness: | 0.25 --2 mm |

| Extra process: | CNC Machining | Size: | 200 mm*180 mm*30 mm |

AL1060 / AL 6063/ CU1100 Process parameter: | |||

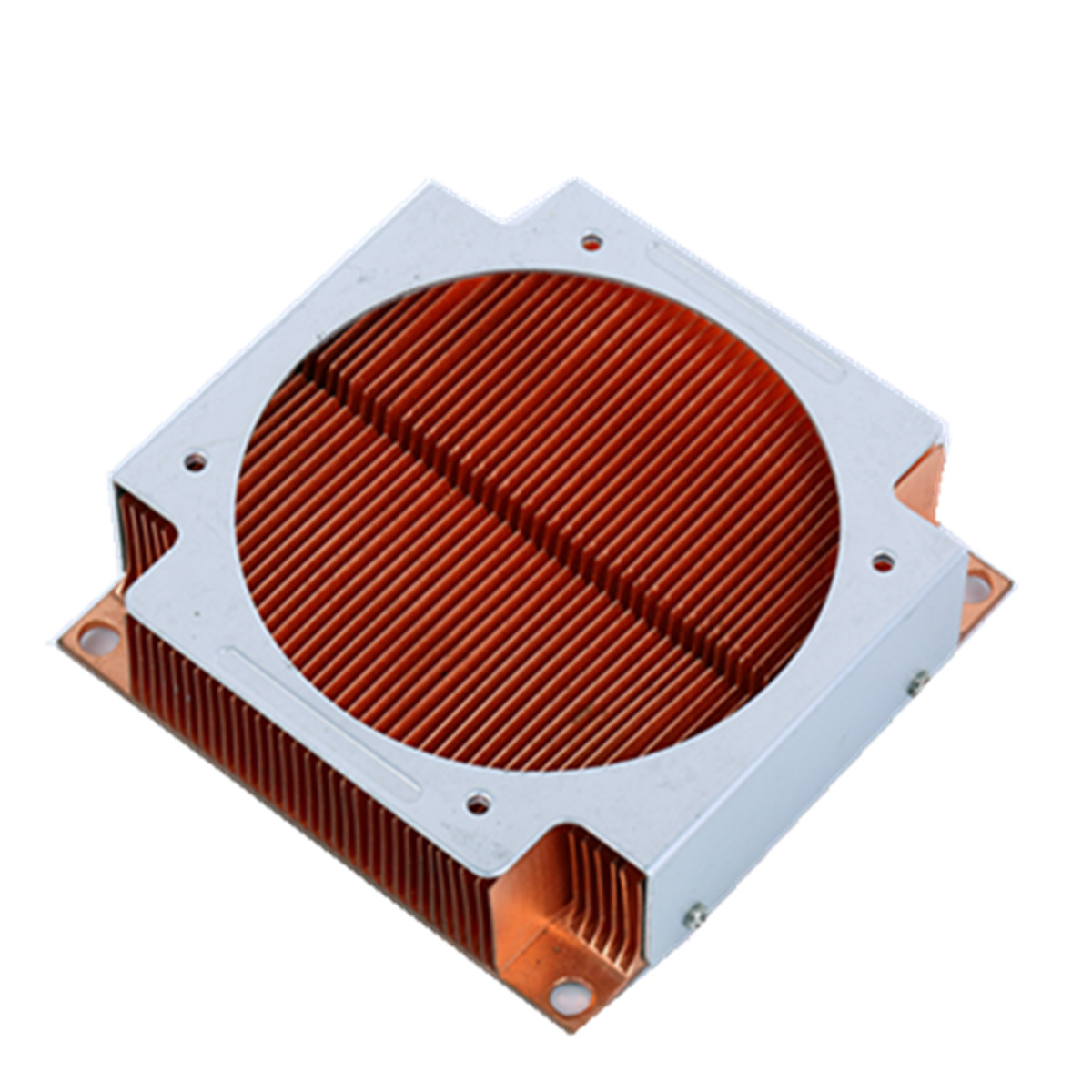

China copper skived fin heat sink

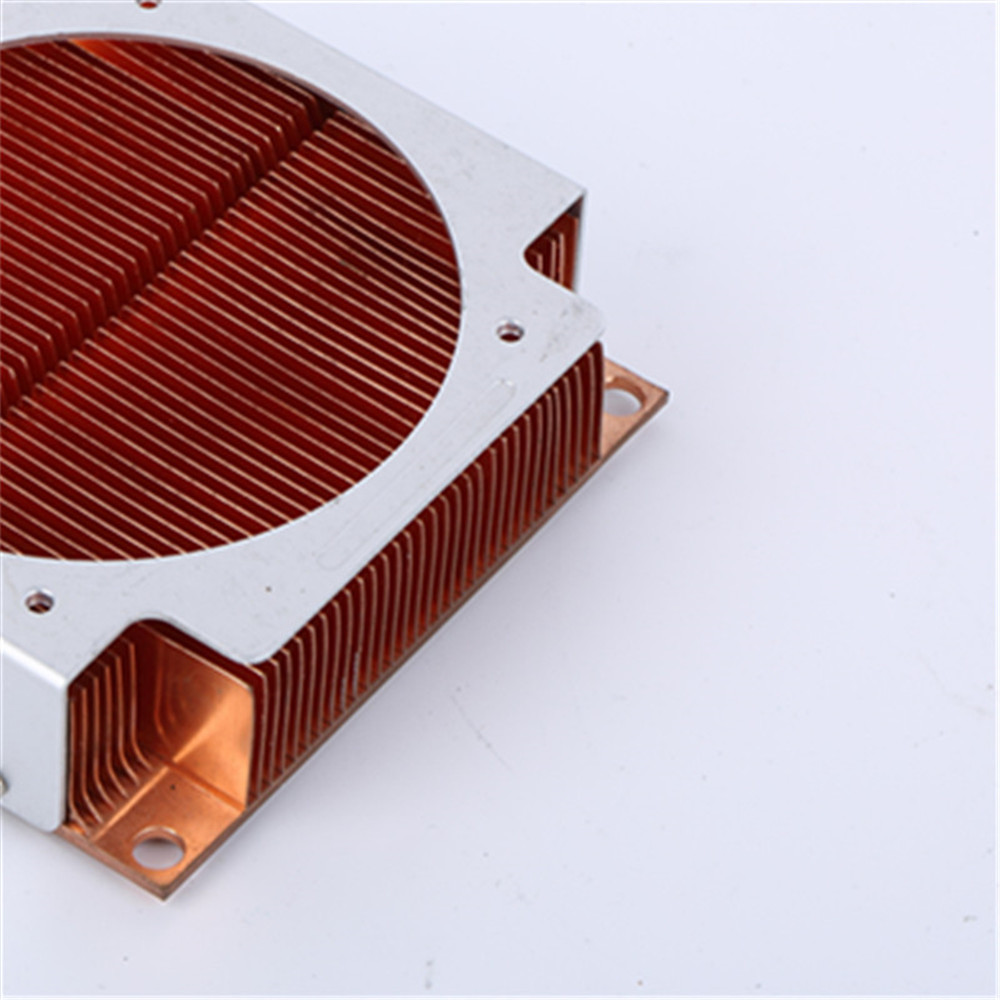

This china skived fin heat sink is made of copper, copper with high thermal conductivity than aluminum,so the skiving process is a good thermal solution for high power cooling . skived fin heat sinks size, 200 mm in length, 180 mm in width and 30 mm in height, it is suitaible for server, cpu and other device cooling. And this copper skived fin heat sink can be alternative to extruded heat sinks, because high density ,high thermal performance, high aspect ratio, excellent performance heat sink can not achieved by extrusion technology.

Lori is a copper skived fin heat sink factory in China, we have more than ten years experience in skived fin heat sink field. when we provide costom china skived fin heat sink for our customer, there are some benefits for skived fin heat sink. Copper skived heat sink manufacturers do not need expensive mold, so customer can save much mold cost.

Lori is heatsink manufacturer china, our skived fin technology enables high fin density and thin fin heat sink by special skived machine cutting. Because of using high precision skived fin technology, the same volume of raw materials can be cut out more heat dissipation area, so copper skived fin heat sink have greater heat transfer than traditional bonded fin or soldering heatsink, so greatly improve heat dissipation efficiency and extend the service life of heating components. Leading the heat innovation high density ,high performance, high aspect ratio, excellent performance.

Copper skived fin heat sinks: When passing through the machine, slabs are skived in a specific angle so as to form and bend the fins. With the repetitive cutting, it forms consistent gaps and structures and can be used for cooling high-power devices under air-cooled conditions. This process can enhance 8~15% of the cooling capacity as compared to the stitched fin process.

Our China Copper skived fin heat sink is used in water cooling head and high-end chip heat dissipation, server and other fields, copper thermal conductivity is good, plus the skived fin technology can achieve the maximum heat dissipation area per unit volume, greatly improve the overall heat dissipation performance

Applied to Communication, UPS, inverter, controller, wind power converter, SVG telecommunication.

◪ In order to ensure the best service to the customer , we have formulated this after-sales service system, the company solemnly to the users of after-sales service work to do the following commitment:

◪ 1.Provide online technical support for customers, and provide consulting services on related issues

◪ 2.From the date of spontaneous delivery, if there is any quality problem or quality objection to our company's customized products, please contact with us in time. After checking and coordinating, we can return and replace the products in time.

Contact

Supplier