China extrusion blow molding machine for sale Customized-J&D WATER

Automatic Alcohol Pet Bottle Blow Molding Machine Blowing machine

Brief introduction

JND series of automatic stretch blow molding machine is widely used to produce varieties of PET plastic container and package for mineral water, beverage, oil, cosmetic and hot infusion, ect.

Controlled by micro-computer with each main process fitted with safety of self-locking, it is operated by only one worker and the total production is completed automatically. Its wide utilization and reliable performance make it become popular and attractive to all bottle manufacturers.

It's strongest point is energy savings. Adopting high pressure clamping, JND automatic stretch blow molding machine makes self-adjustment in accordance with the different pressure needed during production, thus ensures the super clamping force.

While the high pressure sealing system with automatic adjustment permits that mold sealing is under condition of 100% air tightness before blowing and avoid air energy loss owing to incomplete air tightness. With such effective control over air energy and power, it takes a big part to lower costs and improve efficiency.

Product Features

fully automatic PET bottle blow molding machine .

High quality components.

CE certification.

Customerized design.

1 year warranty.

Product Image

Product Specifications

| General Information | JND-E5500 | |||||||||

| Clamping Force | 565KN | |||||||||

| Clamping Stroke | 80-130mm | |||||||||

| Max. Stretching Stroke | 370mm | |||||||||

| Bottom Moving Stroke | 70mm | |||||||||

| Number of Cavities | 6Cavity | |||||||||

| Theoretical Output | 4300BPH | |||||||||

| Max. Mould Thickness | 300mm | |||||||||

| Space Between Tie Bars | 740*535mm | |||||||||

| Electrical System | ||||||||||

| Voltage Standard | 380v/3PH/50Hz or special order | |||||||||

| Number of Heating Zone | 4 Sections | |||||||||

| Total Power (Full Loaded) | 30KW | |||||||||

| Container | ||||||||||

| Max. Container Volume | 2L | |||||||||

| Neck Diameter Range | 16-38mm | |||||||||

| Max. Container Diameter | 100mm | |||||||||

| Max. Container Height | 360mm | |||||||||

| Air system | ||||||||||

| Low Air compressor | 8-10Bar | |||||||||

| High Air compressor | 30-40Bar | |||||||||

| Dimension & Weight | ||||||||||

| Blow molding machine | 5.0*1.83*2.7m | |||||||||

| Preform Autoloader | 1.5*0.98*2.45m | |||||||||

| Net Weight | 4T | |||||||||

Package Includes

35-45 Days

Packing Detail : Wooden Cases

1.Any guarantee of the machines?

The guarantee of our machines is at least one years, also we will send some spare parts along with the machines free of charge.

2.Can you offer the installation and training for the maches?

we can train your engineers in our factory free of charge. It means you can send your engineers to our factory to study and training, we have rich experiences for the training, it is the good way to make sure that you can operate and maintain our machines successfully and for long term normal use. we can send our engineers to your factory to install the machines and train your engineers, we think it is the best way to?help you operate and maintain the machines. we will offer you detail manual books for our machines, also we will make one Video CD to show you how to install and maintain the machines, the CD is the movie for the machines, it will be the great references for you to maintain the machines for the long time.

3.How about the package

wooden case(machines),carton(water dispenser)

4.Delivery time

15-35 days

5.Shipping port

shenzhen,ningbo,shanghai

6.The main transport

Sea transportation,also air transport and car transport

7.What’s the main trade terms

F group and C group

8.What’s the payment

T/T,L/C,Western Union

9.What’s the billing currency

USD

10.Whether to accept custom

yes

11.Accept OEM or not

accept

12.Whether to accept pre-shipment inspection

yes

13.Whether to accept a third-party company detected before shipment

yes

14.Does the machines&water dispenser have any certificates

yes, CE certificate

15.What are your main brand of electrical components?

J&D more than 80% materials of the parts in the products come from world famous manufacturers such as Mitsubishi,Schneider,Omron etc.

16.What’s the minimum order quantity?

1 set.

17.Which country do you export your machines already?

J&D have exported bottling and associated equipment to theUSA,UK,Ireland,Canada,Australia,Mexico,Russia,Africa, the Middle Eastarea etc.

ShenZhen J&D Drinking Water Equipment Co., Ltd. is China's leading manufacturer of bottling equipment and supply the global market with a complete range of bottling equipment and accessories.

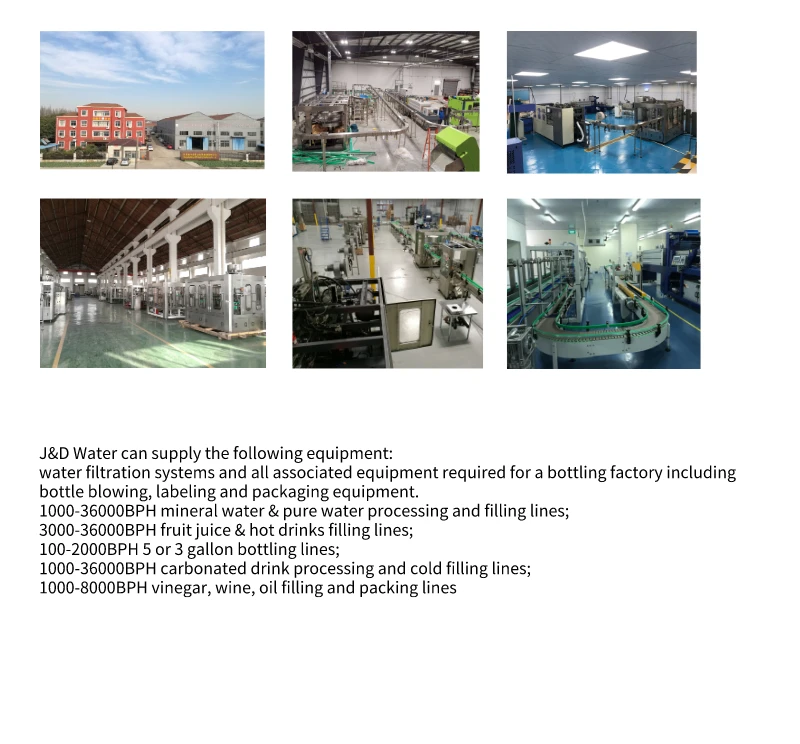

J&D Water can supply the following equipment:

* water dispensers, water filtration systems and all associated equipment required for a bottling factory including bottle blowing, labeling and packaging equipment.

*3000-36000BPH mineral water & pure water processing and filling lines

The warranty or guarantee for our drink equipment:

1, the guarantee of our machines is at least two years, also we will send 3% of sales value as spare parts along with the machines free of charge, the parts will be enough for at least 3 years for the normal operation of machines.

2, we can train your engineers in our factory free of charge. It means you can send your engineers to our factory to study and training, we have rich experiences for the training, it is the good way to make sure that you can operate and maintain our machines successfully and for long term normal use.

3, we will offer you detail manual books for our machines, also we will make one Video CD to show you how to install and maintain the machines, the CD is the movie for the machines, it will be the great references for you to maintain the machines for the long time.

4,another way is that we can send our engineers to your factory to install the machines and train your engineers, we think it is the best way to help you operate and maintain the machines. We have been doing the install jobs for our overseas customers for many years. In this way you need to pay for the travel costs for our engineers, because our initial quotes don’t include the travel costs.

5, All of the electrical parts in our machines are CE or TUV approved. We can offer you UL or CUL/CSA approved parts if you need for the North American markets. The good electrical parts are the guarantee for the good quality for our machines.

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts