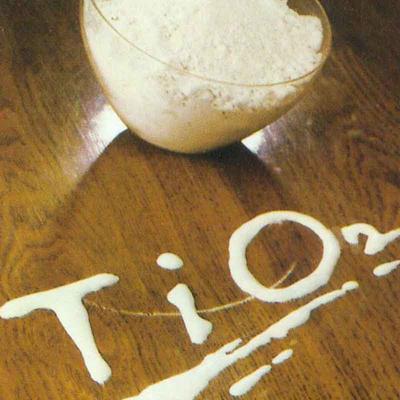

Chromium 560 gloss NANO dry plating Chrome mirror Powder Coating

Product fetures

◪ The metallic pigment can be better melt with the bottom powder and will not jam the spray gun while spraying

◪ Strong adhesion between the metal powder and the base material. The powder is hard to fall off while spraying

◪ Good compatibility for the the spraying effect between recovery powder coating and new powder

◪ The metallic powder is hard to fall off and be oxided and there is no fingerprint problem

◪ Colorful decorative effect is shining since containing metallic pigments like copper and golden powder, silver and aluminum powder, pearlescent pigments

◪ Gloss of chrome effect is above 500-560°,Just like a mirror

application areas

Details

This series of products is by using the advanced Bonding technology equipment to produce surface layer metal powder coating with more bright optical effect, better metalic luster, high utilization of reclaimed powder, high powder spraying rate and the coating that without the defects such as black spots, yin and yang color and fingerprints.

Property

Density: 1.2~1.8g/cm3( Ingredient and color demand)

Particle Size: Purpose demands, standard granularity is 35-40 um, <10um powder <10%, >100um powder <0.5%.

Storage stability: Bonding Metallic Powder Coatings should be stored below 35°C in a dry and well ventilated place away from source of heat, ignition and direct sunlight. If stored in an air-conditioner room, in order to avoid damp again, before using the powder, the powder should be kept at the room temperature or at the same temperature with the spray equipment. Under such condition, the powder can be stored stably for 12 months.

Extended, retest will be required. If the testing result meets the requirement, the powder can still be used.

Note: For the low temperature curing powder with the gloss below 40%(60°),the better stored temperature is below 30℃.

Film Characteristics

Properties | Method | Value | |

Appearance | Visual | A variety of coating effects | |

Impact | GB/T 1732-1993 | 1Kg*50cm | |

Flexibility | GB/T 6742-1986 | ∮2mm | |

Cupping Test | GB/T 9753-1988 | ≥6mm | |

Adhesion | GB/T 9286-1998 | 0Grade | |

Hardness | GB/T 6739-2006 | >H | |

Salt Spray | GB/T 1771-2007 | ≥500h | |

Humility | GB/T 1740-2007 | ≥1000h | |

Film property above may decreases slightly while the gloss decreases. | |||

Spraying | This series of products is suitable for the following spraying methods:corona electrostatic spraying, friction electrostatic spraying, electrostatic fluidized bed spraying,fluidized bed thermal spraying and other spraying methods(For the last 3 methods, please requested in advance) | ||

Film thickness :40~150μm, theoretically 50~80μm. | |||

Curing Guide | 200 ℃ / 10 mins is suggested, and also 160℃/20mins ,180 ℃ / 10 mins etc can be designed according to user’s needs. | ||

Packing & Powder flowchart

Contact

Supplier