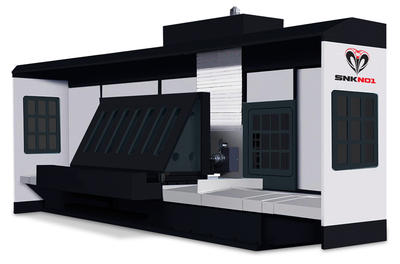

CKA6163A, CKA6180A, CKA61100A Flatbed CNC lathe

Is a CNC horizontal lathe with controls on both Z & X axis. Tons of shaft-type and disc-type workpiece machining can be achieved, such as OD, conical surface, arc surface, end surface, grooving, chamfering, in addition to metric straight thread, end thread, imperial straight thread and conical thread. Fanuc, Siemens, GSK system can be applied to CKA6163A, CKA6180A, CKA61100A. It is suitable for multiple-type complicated workpiece, small and medium production.

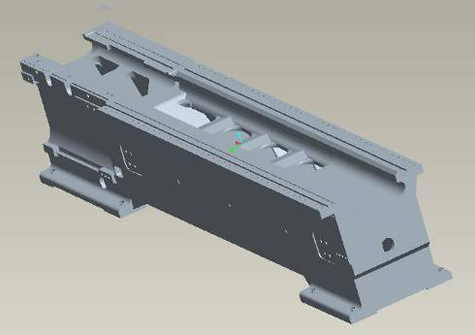

High rigidity structure design

High performance Spindle

Manual 18 step, manual frequency change and auto frequency change are applied on the head stock. Electromagnetic clutch is removed for higher torque and reliability.

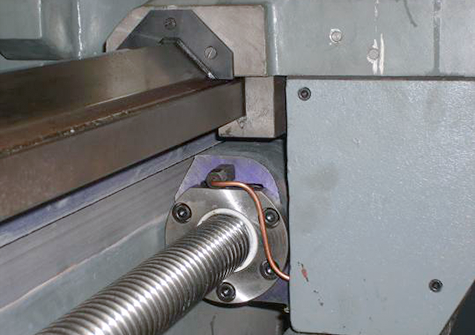

Accurate & rapid vertical and horizontal drive

Auto central lubricating system

Central lubricating on ballscrew and guideway to improve long life span and better movement.

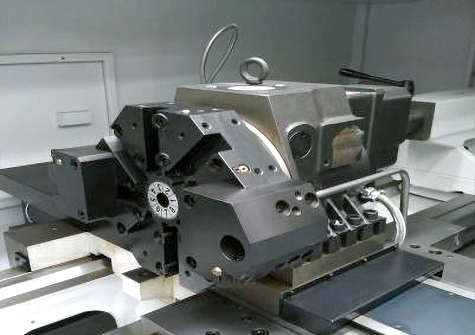

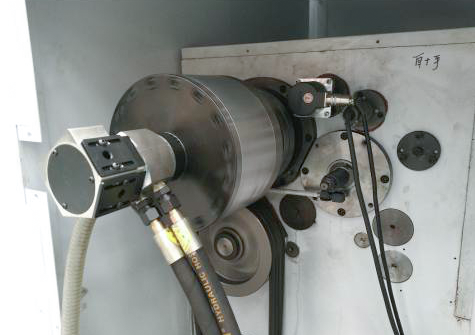

Electrical toolpost

Horizontal 8-position toolpost: Domestic brand name, internal cooling to improve component surface quality and prevent coolant sprinkling.

Chuck

Hydraulic chuck cylinder High accuracy and speed.

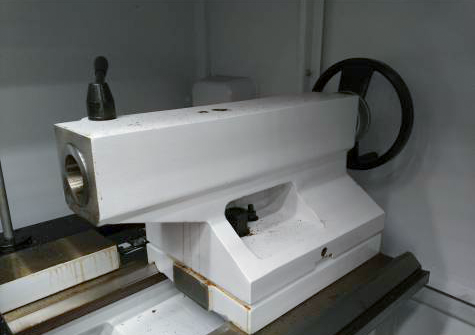

Tailstock

Manual tailstock Easy to operate and fasten.

Full-length guard

1. Technical | Max. Swing over bed | φ630, φ800, φ1000 mm |

Max. Swing over cross slide | φ320, φ490, φ700mm | |

Max component length | 1000/ 1500/ 2000 / 3000/4000/5000mm | |

Max cutting length (Vertical 4-position toolpost) | 785 / 1245 / 1845 / 2745/3785/4745mm | |

Max turning diameter (Vertical 4-position toolpost) | 630, 800, 1000mm | |

(Horizontal 6 position toolpost) | 570, 570, 570 mm | |

(Horizontal 8 position toolpost) | 620, 620, 580 mm | |

Spindle center height | 315, 400, 515 mm | |

Max component weight(Only with chuck) | 1000 kg | |

2. Transmission | Main motor horsepower (regular) | 11kW |

Spindle bore | φ100 mm | |

Spindle bore taper | Front-end metric 120 | |

Spindle nose | C11 | |

Spindle speed (regular) Manual 18step 7.5~1000r/min (7.5, 10, 13, 18, 23, 31, 43, 56, 75, 100, 132, 178, 240, 310, 420, 575, 740, 1000) | ||

(Auto+variable frequency) (10~90, 20~200, 50~445, 110~1000) | ||

Tailstock | Quill diameter | φ100mm |

Quill travel | Manual tailstock 240 mm | |

Taper | Morse 6 | |

Feed system | Toolpost max. travel | 320, 400, 400 mm |

Ballscrew diameter*screw pitch (Z) | φ32×5 (mm) | |

Rapid feed (Z) | 4m/min | |

Max. Cutting speed (Z) | 0.01~2000 mm/min | |

Positioning accuracy | 0.03 mm | |

Repeated position accuracy | 0.012 mm | |

Machining accuracy | IT6~ IT7 | |

Component surface roughness | Ra1.6 | |

5. Toolpost Standard: | horsepower | 400 W |

Speed r/min | 920 r/min | |

Tool shank mm | 32×25 mm | |

Repeated position accuracy | 0.005 mm | |

Tool-change time | 2.9sec(90°) | |

6. Power supply | power | AC 3 PHASE/380 V±10% /50Hz±2Hz |

CAPACITY | 24KVA | |

7. Cooling system | TANK VOLUME | 25L |

Horsepower | 150 W | |

Flow | 25 L/min | |

8. Size & weight | (Ø630, Ø800) | 3455x2020x1805(1000) |

3905x2020x1805(1500) | ||

4505x2020x1805(2000) | ||

5405x2020x1805(3000) | ||

6455x2020x1805(4000) | ||

7535x2020x1805(5000) | ||

(Ø1000) | 3455x2020x2000(1000) | |

3905x2020x2000(1500) | ||

4505x2020x2000(2000) | ||

5405x2020x2000(3000) | ||

6455x2020x2000(4000) | ||

7535x2020x2000(5000) | ||

Weight | (Ø630) | 4800/5100/5600/5900/7100/8100kg |

(Ø800) | 5300/5600/6100/6400/7600/8600kg | |

(Ø100) | 5600/6000/6500/6800/8200/9200kg | |

Standard/ optional specification

Guideway& ballscrew | LM guideway | ||||||||

● | |||||||||

Spindle | Belt | NSK bearings | Domestic bearings |

| |||||

● | ○ | ● | |||||||

Tailstock | Manual | Hydraulic |

| ||||||

● | ○ |

| |||||||

Toolpost | Vertical 4-position external cooling electrical motor | Horizontal 6-position electrical motor | Horizontal 8-position electrical motor | Vertical 6-position electrical motor | |||||

● | ○ | ○ | ○ | ||||||

Chuck/cylinder | Manual | φ315mm/12"Hollow/solid hydraulic chuck | φ400mm/15"Hollow/solid hydraulic chuck | ||||||

● | ○ | ○ | |||||||

Controller system | FANUC 0i-mate-TD | GSK | Siemens | Other | |||||

○ | ○ | ○ | ○ | ||||||

Hydraulic components | BLT | Wealink | |||||||

○ | ○ | ||||||||

Chip container plate | Chip conveyor | trolley | |||||||

● | ○ | ○ | |||||||

Cooling system | Cooling pump and tank | Fan Electrical cabinet | AC Electrical cabinet | ||||||

● | ● | ○ | |||||||

Others | Lamp | Foundation bolts& buts | |||||||

● | ● | ||||||||

Technical doc | Steady rest | Follow rest | |||||||

● | ○ | ○ | |||||||

Accessory, special order accessory

Accessory

No | Item | Model | QTY | Notes |

1 | 3 Jaw chuck | K11315C/C11 | 1set | |

2 | Wrench | S91-1A: 8×10, 11×13, 16×17, 18×19, 22×24, 27×30, 32×36; | 1set | |

3 | Center | DM116;GB 9204.1 | 1 | |

4 | Oil gun | 80~100ml | 1set | |

5 | Washer | CW6163E-10A705 | 1set | 6pcs |

6 | Keys | 2 | Belt gate. Electrical cabinet | |

7 | Documents | Instruction, qualification certificate, | 1set |

2. Special order item

No | Item | Model | QTY | Notes |

1 | Live left | D566, JB/T3580.1 | 1 unit |

|

2 | Wrench | 135~165; JB1019 | 1 unit |

|

3 | Wedge | S78 228-54-60 | 8 |

|

4 | Center | DM116; GB 9204.1 | 1 | Spindle left |

5 | Center sleeve | CW6163E-20702 | 1 | M6 |

Main purchased parts list

No. | Item | Supplier | Notes |

1 | Spindle bearing | Domestic brand name | |

JAPAN NSK | Special order | ||

3 | Triangle belt | Domestic (narrow V-shape) | |

4 | X-axis ball screw | DMTG | |

5 | Z-axis ball screw | DMTG | |

6 | Ballscrew bearing | ZHENJIANG | |

7 | Tooth belt and wheel | QINGDAO | |

8 | Vertical 4 position Tool post | WAFANGDIAN | |

9 | Horizontal 6position | YANTAI MACHINE TOOL | Special order |

10 | Horizontal 8position | YANTAI MACHINE TOOL | Special order |

11 | Brake | DMTG | |

12 | Chuck | WAFANGDIAN | |

13 | Hydraulic solid chuck&cylinder | Taiwan/domestic | Special order |

14 | Hydraulic hollow chuck&cylinder | Taiwan/domestic | Special order |

15 | Regular main motor | Domestic brand name |

|

16 | VFD main motor | Domestic brand name |

|

17 | Lubricating motor | Dalian |

|

18 | Cooling motor pump | Dandong Motor |

|

19 | chain | Agiletech |

|

20 | Central lubrication | Yongjia liubian |

|

21 | Hydraulic station | Dalian or BLT | Special order |

22 | Controller | FANUC, DMTG, GSK etc |

|

23 | Heat exchanger | Tongfei/leibo |

|

24 | AC | Tongfei/leibo | Special order |

25 | Electrical components | Imported or domestic |

|

26 | Frequency converter | Delta or domestic | VFD |

27 | Safety gate lock | Omron |

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Building Material Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts