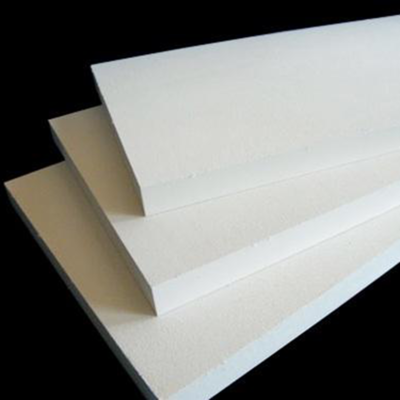

Low cement castables are new castables with a low binder content. The key point is the use of ultrafine particles not exceeding 1 μm. Its thermal shock resistance, slag resistance and erosion resistance are significantly improved, surpassing similar refractory bricks. Further reducing the binder content can produce ultra-low cement castables and cement-free castables

Low cement castables refer to castables with lower cement usage. The amount of cement used for refractory cement castables is generally 15% to 20%, and the amount of cement for low cement castables is about 5%, and some even decrease to 1% to 2%. The purpose of reducing the amount of cement is to improve the fire resistance of the castable.

It relies on the addition of several special raw materials to obtain good performance: First, pure calcium aluminate cement, because of the high content of effective mineral CaO·Al2O3, the lesser the incorporation, the desired strength can be obtained. The second silica fume is a glass microsphere having an SiO2 content of between 93% and 98% and an average particle diameter of about 0.5 μm. After the addition of silica fume, the flowability of the castable is good, the water requirement for molding is low, the sintering temperature is low, and the performance after heat treatment is avoided. Third, alumina fine powder, which is relatively easy to participate in the reaction and improve the fire resistance of the material. Fourth, the water reducing agent, which can adsorb on the surface of the powder, thereby generating electrostatic repulsion to disperse the powder, thereby further exerting the function of the fine powder.

Low cement castables are high-tech refractories developed on common castables using rheological principles, tightest packing theory and ultrafine powder technology. It has the characteristics of low porosity, small pore size, high density, good volume stability, high strength and small water addition, and overcomes the characteristic that the strength of ordinary castables drops significantly at 800-1200 °C, and increases with temperature. When it is raised, the thermal shock resistance of the furnace body can be more than doubled.

Index | Fire clay | High alumina | Corundum | |

Al2O3 % | 45 | 75 | 92 | |

SiO2 % | 50 | 12 | 5 | |

CaO % | 1.8 | 1.5 | 1.5 | |

Bulk density g/cm3 | 110°C,24h | 2.3 | 2.6 | 3 |

| 1350°C,3h | 2.26 | 2.61 | 3.1 |

Compressive strength MPa | 110°C,24h | 72 | 75 | 85 |

| 1350°C,3h | 90 | 115 | 125 |

Reheating linear change % | 1000°C,3h | -0.3 | -0.2 | -0.2 |

| 1350°C,3h | ±0.3 | ±0.5 | ±0.5 |

water content to mixture % | 6.0-6.5 | 6.0-6.5 | 6.0-6.5 | |

Service temperature °C | 1450 | 1600 | 1700 | |

application

Product | Application |

Shaking low cement or ultra-low cement castable | heating furnace,heat treatment furnace,furnace cover of electric furnace,shaft kiln,rotary kiln, trough of blast furnace,steel ladle,hot metal ladle |

Self flowing low cement or ultra-low cement castable | Water cooling tube of heating furnace, ladle gas components,catalytic cracking reactor of petrochemical industry etc high temperature zone |

1. Payment: T/T, Western Union,LC; Usually 30% deposits,70% balance before delivery or negotiations to solve.

2. MOQ: Usually 1Tons,Customers can order certain PCS for special brick.

3. Quality Warranty: 1 years.

4. Package Informations:1.On wooden pallets with plastic cover, 2.According to customer's requirements.

(1)Wooden pallet size:930*930mm,Load weight of each pallet:1.5-2.0 Tons.

(2)20 Foot Container can be loaded 25Tons,40 Foot Container can be loaded 28Tons.

Advantage

1. We have been in this industry for over 30 years, with the most professional production technology.

2. Our company to provide the best quality service, at any time for the customer to solve the problem.

3. We have an experienced team of work and production base.

4.We offer the highest quality products and competitive prices.

5. We have a professional enterprise qualification certification and product inspection certificate.

6. We have effective logistics centers, factories and warehouses to ensure fast delivery of the domestic market and foreign markets.

FAQ

1.Why choose us?

We had been in this line for more than 30 years.

Our products have been exported to Asia Southeast America North customer recognition.

We offer competitive prices.

We can provide customers with a reliable and efficient service.

2.Do we supply samples?

Yes,we would like to offer any free sample you required.

3.What is MOQ?

MOQ may vary by customer's special requirement,we try our best to meet your businessre quirement.

4.Can the clients visit your factory?

Of course,we accpet size and color customized.

5.Can the clients visit your factory?

Of course ,welcome to visit our factory any time.

6.Which payment terms do you accept?

L/C

T/T

Westen Union

7.After an order is placed,when to deliver?

10~30days.

8.How to ensure the quality of shipping products?

All produsts have to be through strict inspection before delivery.

We not only have to ensure the quality in business but also the credibility in our market.

9.Which certifications do your company have ?

ISO9001 and Test Report,we could provide other necessary certifications if required.

Contact

Supplier