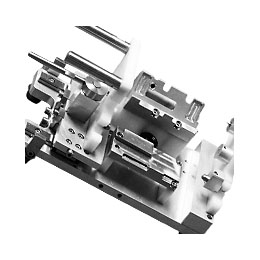

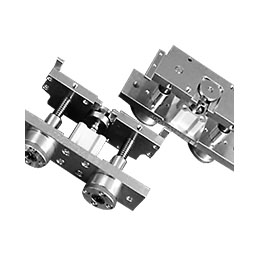

CNC Elements Of oxidation-resisting carbon steel Machined industrial equipment

Product Information

****Key point: Elements Of oxidation-resisting carbon steel Machined

****Material: carbon steel, Color Anodizing

**** Specialized in various metal part and mold part producing, CNC machining and metal stamping, forging and casting

**** All parts can be machined with tiny tolerance, precise dimensions and a smooth surface.

****Advanced measuring and testing equipment: projecting apparatus, micrometer, height gauge, projector measuring machine, coordinate measuring machine (CMM),roughness tester, hardness tester, concentricity tester etc.

****Inspection report and material test certificates are available upon requestã

**** Deburring by hands and remove off scratch when found.

****We have done different type of material surface treatment: a. Stainless steel: electro polishing, chemical polishing, passivation, and chrome. b. Aluminum alloy: Sandblasting, ordinary and hard anodizing, passivation, painting and dusting of true color, black, gray and red, etc. c. Carbon and alloy steel: nigrescence, zinc, chromium, nickel plating, electroless nickel, phosphating, painting and dusting and so on.

CNC Parts Main Features

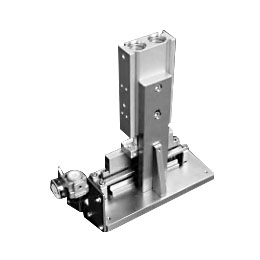

Electronic pressing assembly fixture Designed by Aidely according to customer's requirement

▶ We offer a variety of assembly and test services for the manufacturing industries.

▶ With vertical integration in precision machining, superior Supply Chain Management tools, guarantees you the highest quality and quickest turnaround time.

▶ Our program managers stay in constant communication with customers to ensure a smooth transition during build.

▶ We are ready to accommodate any of your requirements.

▶ MFG Engineering Services for Assembly Builds

▶ We have done different type of material surface treatment:

A: Stainless steel: electro polishing, chemical polishing, passivation, and chrome.

B: Aluminum alloy: Sandblasting, ordinary and hard anodizing, passivation, painting and dusting of true color, black, gray and red, etc.

C: Carbon and alloy steel: nigrescence, zinc, chromium, nickel plating, electroless nickel, phosphating, painting and dusting and so on.

Fixture and Assembly

Design and provide tooling and fixtures according to customer's needs for automotive, avold employees from tired and reduce the defective rate to Improve the production efficlency.

Featured products

Description

A. The surface appearance requirements can be reached by anodized processing with imported aluminum base material and strict process parameters control.

B. It is rotated by four axes to eight different angles to finish 16 holes positions and form a complex cavity. Relative position demands are higher. After the completion, the lateral holes should be blocked with 7 MPa pressure for testing.

C. After the oxidation, more than one hole with H7 precision of aperture should be guaranteed.

D. Our ultimate goal is to provide seamless transition of your prototypes to the mass production phase

E. With vertical integration in precision machining, superior Supply Chain Management tools, guarantees you the highest quality and quickest turnaround time.

Contact

Supplier