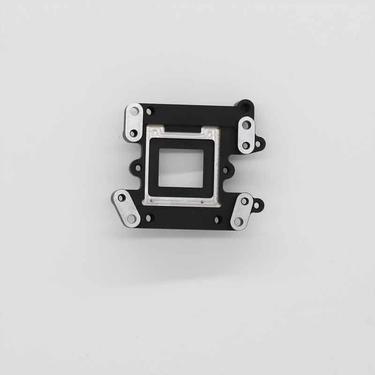

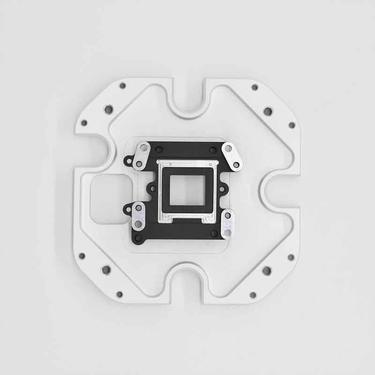

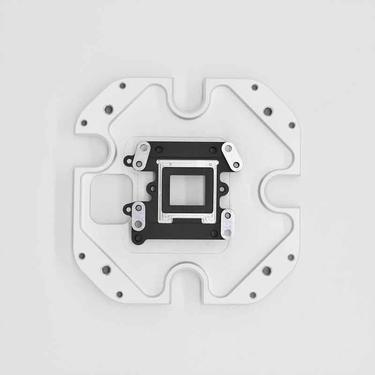

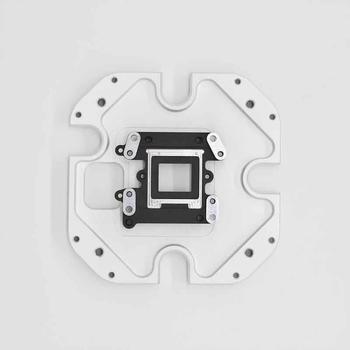

CNC Machining Sensor bracket parts

sensor assembly base plane, wall thickness 0.3mm, planeness requirements less than 0.02mm, planeness finishing using single-edge PCD milling cutter, sand blasting pressure >Mpa0.35, we made a special fixture, make it into the fixture for sand blasting, standard 120 mesh glass beads.

Sand blasting

Sand blasting is powered by compressed air to form a high speed jet beam to spray (copper ore, quartz sand, carborundum, iron sand, sea sand) to the surface of the workpiece to be treated, so that the appearance or shape of the workpiece surface can be changed. Because of the impact and cutting effect of abrasive on the surface of the workpiece, the surface of the workpiece can obtain certain cleanliness and different roughness, and the mechanical properties of the surface of the workpiece are improved, so the fatigue resistance of the workpiece is improved. It increases the adhesion between it and the coating, prolongs the durability of the coating, and is also beneficial to the leveling and decoration of the coating.

This aluminum alloy precision milling service part adopts the milling method of CNC. The surface treatment used is sandblasting and oxidation. Generally, the aluminum alloy parts with oxidation process need sandblasting to reduce the surface roughness on precision milling service parts.

Contact

Supplier