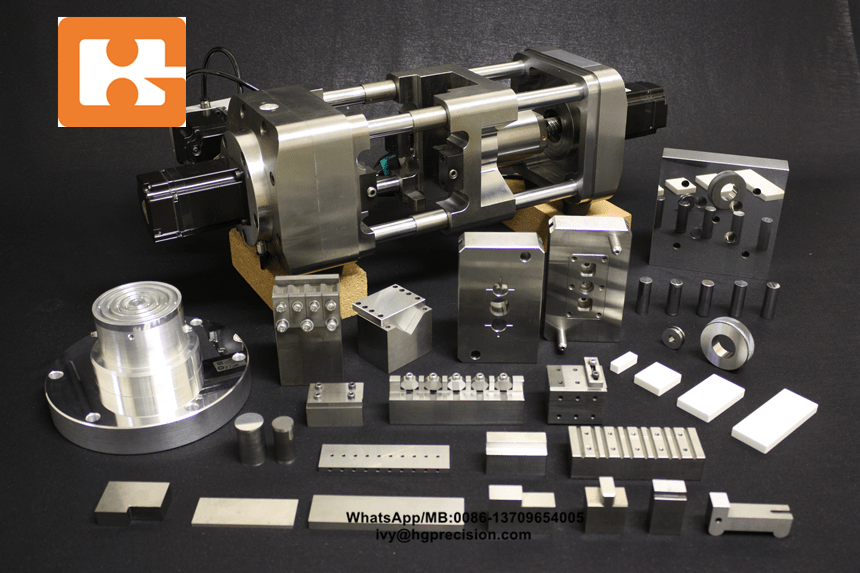

CNC Turning Hardware For Silencer Assembly

Part Description:CNC Turning Hardware For Silencer Assembly

Product Detail:

Material | metal, like Aluminum, steel, copper, |

Surface treatment | Anodizing, Coating, plating, heat-treated. |

machining products | customized |

Tolerance | 0.01mm |

machinary Axis | 3, 4, 5 Axis |

lead time | 7-20 days |

files accepted | PDF, STEP, IGES, IMAGES, DWG, DXF |

Product Keywords | CNC turning parts for silencers assembly(vehicle assembly) |

Equipment Capabilities:

1. CNC Machining Center: 12 sets

2. CNC Lathe: 8 sets

3. Automatic lathe: 10 sets

4. Universal milling: 15 sets

5. Wire EDM: 6 sets

6. Drilling machine: 8 sets

7. Two dimensions measuring instrument: 2 sets

8. Altimeter: 1 sets

9. 3D Coordinate Test: 1 set

Custom CNC Machining Processes & Capabilities:

Milling, turning, cutting, punching, bending, routering, welding, shearing, deburring, drilling, knurling, forming, boring, counterboring, countersinking, pocketing, reaming, tapping, facing, brushing, thread milling, anodizing, polishing, powder coating, laser engraving, assembly, packaging, labeling and kitting, and CAD/CAM graphics.

Why Choose Us?

High Quality- Quality Raw Material, Advance Facilities, Fine Procedures

High Productivity

Fast Delivery

Leading Level R&D Department

Experienced Marketing Manager

Professional Design Department

Accept OED&ODM

Excellent After-Sales Service

Contact

Supplier