Complex high precision copper machining parts optical-communication

Product Information

=== Complex high precision copper machining parts supply

=== Customized products completely according to your drawings or samples.

===Produce precision turning Components / Precision Shaft Material steel, stainless steel, carbon steel, free cutting steel, aluminum, brass, copper, alloy, pom, PTFE Finish nickel ,zinc nickel, chrome, bluing, black oxide, satin chrome, zinc, Anodizing, etc.

===All kinds of finish treatments can be available, like power coating, hard anodizing, zinc plated, plating, oxidation, blasting, painting, anodizing, heat treatment

===ISO9001: 2008 certified.

===We have good cooperation with many famous companies for nearly 10 years such as Leica, Epson, Sanyo, Mindray, Brother, SC, Danaher, Hach etc.

===IPQC inspect each during every step; 100% inspection before shipment by micrometer, height gauge, projector measuring machine, coordinate measuring machine (CMM), roughness tester, hardness tester, concentricity tester etc.

===Small order accepted for machined parts to help your urgent demand by quick delivery also help you keeping low stock rate.

===Our ultimate goal is to provide seamless transition of your prototypes to the mass production phase

==== Safe packages and quick delivery with DHL, UPS, FedEx or TNT, sea delivery can be chosen too.

CNC Parts Main Features

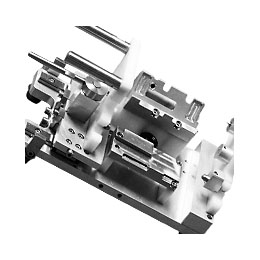

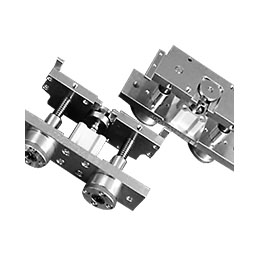

Electronic pressing assembly fixture Designed by Aidely according to customer's requirement

▶ We offer a variety of assembly and test services for the manufacturing industries.

▶ With vertical integration in precision machining, superior Supply Chain Management tools, guarantees you the highest quality and quickest turnaround time.

▶ Our program managers stay in constant communication with customers to ensure a smooth transition during build.

▶ We are ready to accommodate any of your requirements.

▶ MFG Engineering Services for Assembly Builds

▶ We have done different type of material surface treatment:

A: Stainless steel: electro polishing, chemical polishing, passivation, and chrome.

B: Aluminum alloy: Sandblasting, ordinary and hard anodizing, passivation, painting and dusting of true color, black, gray and red, etc.

C: Carbon and alloy steel: nigrescence, zinc, chromium, nickel plating, electroless nickel, phosphating, painting and dusting and so on.

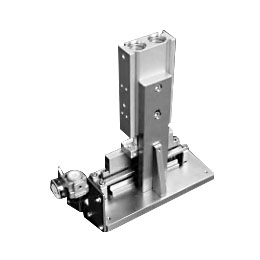

Fixture and Assembly

Design and provide tooling and fixtures according to customer's needs for automotive, avold employees from tired and reduce the defective rate to Improve the production efficlency.

Featured products

Description

A. The surface appearance requirements can be reached by anodized processing with imported aluminum base material and strict process parameters control.

B. It is rotated by four axes to eight different angles to finish 16 holes positions and form a complex cavity. Relative position demands are higher. After the completion, the lateral holes should be blocked with 7 MPa pressure for testing.

C. After the oxidation, more than one hole with H7 precision of aperture should be guaranteed.

D. Our ultimate goal is to provide seamless transition of your prototypes to the mass production phase

E. With vertical integration in precision machining, superior Supply Chain Management tools, guarantees you the highest quality and quickest turnaround time.

Contact

Supplier