Corrosion Resistance Tester

Corrosion Resistance Tester

:Salt Ccorrosion Chamber Video

:Salt Ccorrosion Chamber Video  : Corrosion Resistance Tester.PDF

: Corrosion Resistance Tester.PDF

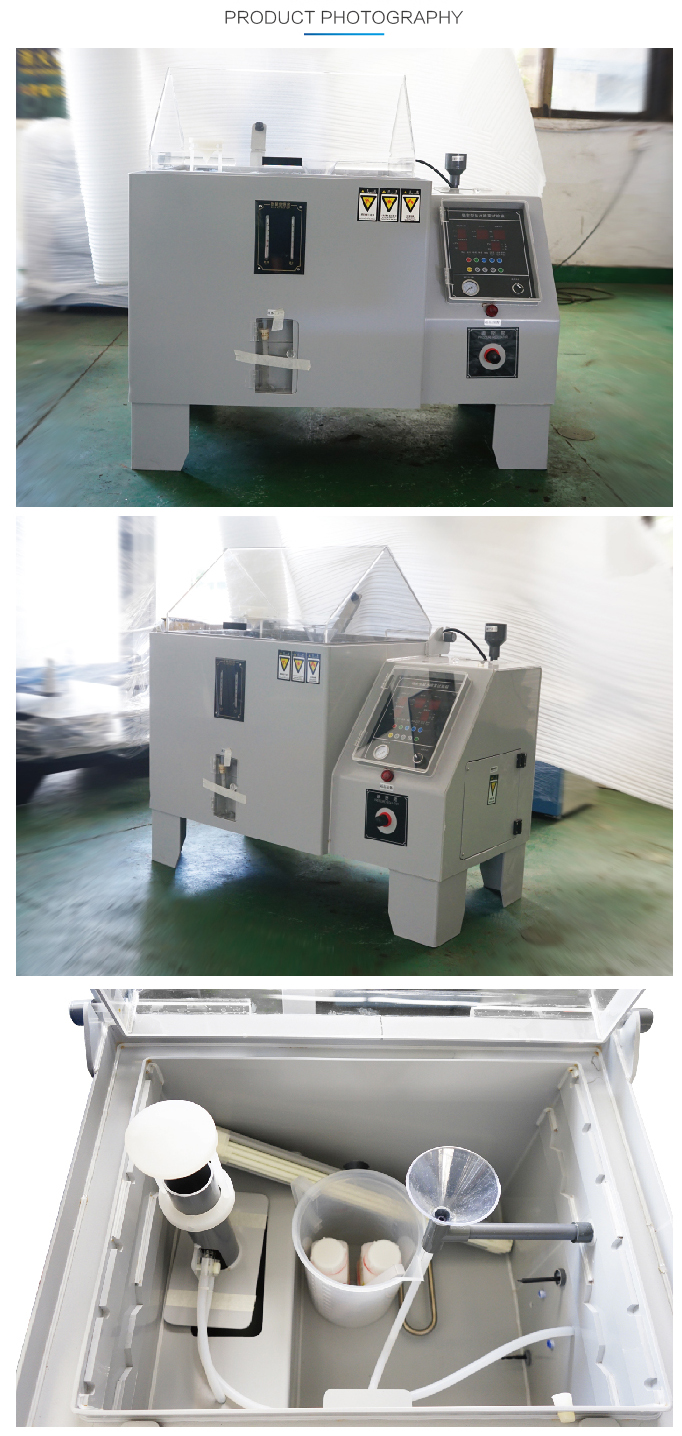

Corrosion Resistance Tester adapted to the surface treatment of various materials, including paint, electroplating, organic and inorganic coating, anode processing, antirust oil and so on, after these anti-corrosive treatment to test the corrosion resistance of their products.suitable for parts, electronic components, metal materials, protective coatings and industrial products.

Model | HD-E808-60 |

Internal Size (W*D*H) | 600*450*400mm |

External Size (W*D*H) | 1060*580*1050mm |

Chamber material | P.V.C rigid plastic plate, thickness 8mm |

Sample tray | Diameter 10mm glass fiber rod, anti-rust V-shape plastic steel to make sure sample in 15~30 degree inclined |

Temperature Range | Room temperature ~ 55℃ |

Temperature Fluctuations | ≤±0.5℃ |

Temperature Uniformity | ≤±2℃ |

Temperature Precision | ±1℃ |

Spraying method | Continuous and Periodic spray type |

Test Chamber Temperature | Salt Spray Method (NSS ACSS)35±1℃ |

Saturated air Barrel Temperature | Salt Spray Method (NSS ACSS)47±1℃ |

Brine Temperature | 35℃±1℃ |

Spray Quantity | 1.0~2.0 ml / 80cm2 / hr |

PH value | Salt Spray Method (NSS ACSS6.5~7.2) |

Lab Volume | 108L |

Brine Tank Capacity | 25L |

Multiple Safety Protection Devices | Current discharge protection, over pressure protection, over temperature protection, over load fuse protection |

Accessories | Testing Salt/ Measuring tank/Nozzle Equipment x 1 set |

Air source | 1HP Air pump (provided by buyer) |

The table parameters is for the company Standard Model parameters, we support customer customization parameters

ASTM B117-08, ISO 9227...

And IEC, MIL, DIN, ASTM and other standards equivalent to

1, Durable hard 8 mm PVC construction, anti-corrosion and easy to clean.

2, Reservoirs with mixing system on stand.

3, Separate heating system apart from salt testing chamber to ensure accurate result and protect circuit.

4, Exposure zone lined with corrosion-resistant PVC sheets.

5, Clear cover allows viewing of test conditions.

6, Peaked cover prevents dripping of condensation onto samples.

7, Water seal and water level protection system.

8, Heated humidifying tower with air relief valve, adjustable tower tip to orient salt fog.

9, Automatic DI water fills to humidifying tower.

10, Digital temperature control.

11, Integral over-protection on heaters.

12, Low water cut-off protection on humidifying tower.

1, the salt spray chamber internal parts: tower spray device, funnel, rod, V-type sample holder installed.

2, connected to the gas supply, the power is turned on, turn on the power switch.

3, in the pressure tank and cabinets add water, two low level light exterminate stop adding water, at the water seal groove seal.

4, purified water and sodium chloride salt in a ratio of 1:20 with a good. The solution was poured into the reagent with a good entrance (low saline to exterminate a lamp).

5, we can open all the lamps burn out operation, spray, time switch, switch demisting before opening end of the test.

6, according to the test requirements for equipment and cycles for continuous spraying mode (continuous spray T1, T2 tables are all set to 0, T1 is set to intermittent spray working time, T2 is time to rest).

Other models:

| Salt Spray Test Chamber |

| Salt spray corrosion testing chamber |

| Salt Spray Corrosion Tester |

Download: Corrosion Resistance Tester.PDF

If want to know more,please click "contact us"

If you face any problems in future during testing process we promise we will give you a reply within 48 hours and solution provide within 3 working days. We can offer operation video and English operation muanual. We can provide video-conference. If customers require on-site service, the transport and travel expense shall be borne by customer.

1. Pre-service

--24 Hours online service for your consult.

--Help choose right model,and a series of service,person,advise.

2. Middle service

--Give you best offer

--Provide discount for many sets order

--Do customer's request

--Choose payment term you convienent.

--Promptly production and delivery,inform you in time.

--Can provide invoice value as you like to decrease your tax.

3. After sale service :

--1 year warranty service and all life maintenance.

--Technical Egineer are avalible for oversea trainning.

--Free change for some parts

--Remote control technical consult

--Free installation DVD

--Maintenance plan

4,Commitment:

We will sign a letter of commitment while we sign the contract, which will improve your confidence to us.

5,Good Packaging:

Simulation Animatronic Customer Triceratops are covered with air bubble film before put them into the wooden case, which not only has good shock absorption, impact resistance, heat sealing and also has the advantages of nontoxic, odorless, moisture corrosion, good transparency etc.

FAQ:

Q:Are your company a trading one or a factory?

A:Factory + trade (integration),More than 12 years focusing on test equipment field,6 years exporting experience.

Q:What about the warranty with after - sales services?

A:The testing machine is guaranteed for 12 months by HAIDA,we can help you to repair your problem controller freely,even it's not from our factory. After the warranty, the professional aftersales service team will provide perfect technical support and help guests solve problems encountered while using our product, handles guest problems and complaints in a professional and timely.

Q:What about the product' services and quality?

A:Each equipment must be carried out 100% quality examination and test when shipping and delivery goods. Product use training, each of our product provide video training to show you how to install & operate. We can arrange engineer to train the operation of equipment to customer’s company when you need. products are widely recognized and trusted by users.

A :Considerate Service Different countries plugs, manually change the-voltage from 110V to 220V, insurance indicator.

How to Contact Us?

Please Send your inquiry Details in the below for our quotation,Click "Send" Now!

Contact

Supplier