cost-benefit automatic machining heavy cutting and turning CNC machine C20 with tailstock C20

cost-benefit automatic machining heavy cutting and

turning CNC machine C20 with tailstock

Features:

1.With tailstock,tailstock adopt YASKAWA (japan) 1.8 KW torque servo motor .

2.Use Germen 8 station or 10 station turret.

3.Z axis has a longer travel ,can reach 380mm , the model is able to finishing long shaft parts.

4.Z axis use biger guide rail Ø 40 mm, feeding system adopts the bigger diameter and pre-tension

of ball screw, which strengthen the rigid of ball screw that can prevent shape transform.

5.Advantages:big load-carrying capacity,high accuracy,reasonable structure and easy to handle.

6.The key parts include lathe bed,gang type cutting tools and so on , all these parts adopt high

strength cast iron which make machine more stable and can load heavy cutting and keep a long

term accuracy.

7.Spindle drived by high power and high torque motor,so machine can achieve a high precision

cutting even in the case of low rotating speed.

8.All the guide rail use roller guide rail,adopt the method of scraping the inquiry can ensure the

maximization of the contact area.

9.The machine is widely use in machining flashlight, printers shaft, motor shaft processing

industry, etc.

Technical parameter for heavy cutting and turning cnc machine C20;

| Technical parameter of heavy turning and cutting cnc lathe machine C20 | ||

| NC | TAIWAN/ CHINA | LNC/SYNTEC/SIMENS |

| Spindle | TaiWan Posa | A2-6/56 spindle |

| X/Z axis servo motor | Japan YASKAWA | 1.3 KW or 1.8 KW ( optional ) |

| tailstock motor | Japan YASKAWA | 1.8 KW |

| Spindle motor/servo motor | Shang hai senlima | 4.0 KW/5.5kw |

| Frequency converter | megmeet | 5.5 KW/7.5kw |

| Lead screw / lead rail | TaiWan Hiwin,PMI | C3, level two |

| Bearing | Japan NSK,Germany FAG | level four |

| Lead screw coupler | from Germany | precision |

| Parameters | C20 | |

| Capacity | Spindle bore | ¢66 mm |

| Max. material diameter | ¢51 mm | |

| Max. machining diameter | ¢450 mm | |

| Max. length of machining | 330 mm | |

| Max. travel of x-axis | 230 mm | |

| Max. travel of z-axis | 380 mm | |

| rapid speed (x-axis/z-axis) | 20 m/min | |

| reposition accuracy (x/z) | x≤0.007 mm z≤0.015 mm | |

| Motor | spindle variable frequency motor | 5.5 KW |

| Max spindle speed | 3500 rpm | |

| x-axis servo motor | 1.3KW or 1.8KW (optional ) | |

| z-axis servo motor | 1.3KW or 1.8KW (optional ) | |

| Tailstock | quantity of turret tools | 8 |

| tailstock travel | 330 mm | |

| thimble taper | MT4 | |

| diameter of tailstock | ¢72 mm | |

| Other | total power | 15 KW |

| size(mm x mm x mm) | 2700×1800×1900 | |

| N.W. | 4100 KGS | |

Our Service

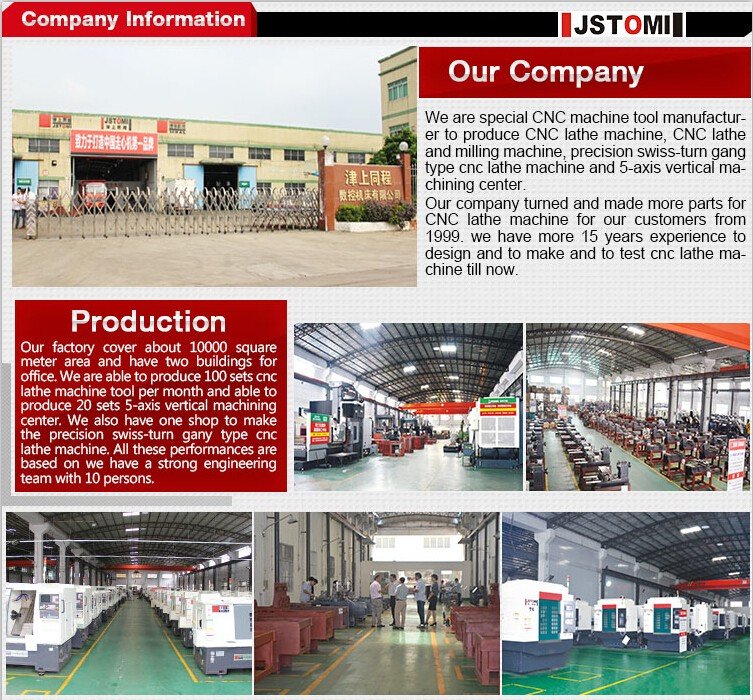

1. We specialized in manufacturing slant bed cnc lathe machine for 10 years , technology come out in front

in the industry.

2. Our supply ability is sufficient to guarantee the customers demand.

3. Where you can buy all the Equipments for your market ,at the mean time the customers can enjoy the

long-term technical advisory services in our company.

4. Our products can be OEM ,meet your special needs.

5. Quick delivery, Competitive price ,high quality and long term service to out customers.

6. There is a long-term cooperation with the shipping company, can make the goods more quickly and

efficiently so that can delivered safely to the designated place as guest.

7. We will provide best after sale service for the guests which try my best to meet the requirements

of guests.

1. You can hold much lathe knife? There are several options?

Slant bed lathe usually can install 5-7 tools, turret lathe can install 8/10 tools on turret,2-3 tools

on table.

2. How to choose the best fit for your machine?

If you have special request for the machine tool configuration,And the budget is limited,We can

also according to your need to change the configuration. Thus pls provide us your machining

drawing, we are very glad to design a specific process solution for you and recommend you a

proper cnc machine model.

3. About OEM

Our products can be OEM ,meet your special needs. We have a very rich experience and strong

machine tool research and development capability. We are very willing to offer you customized

highly-efficient equipment as long as you have certain amount of needs.

4.About Shipping

There is a long-term cooperation with the shipping company, can make the goods more quickly

and efficiently so that can delivered safely to the designated place as guest.

5. About supply ability

Our supply ability is sufficient to guarantee the customers demand. Where you can buy all the

Equipments for your market ,at the mean time the customers can enjoy the long-term technical

advisory services in our company.

6. About after sale service

We will provide best after sale service for the guests which try my best to meet the requirements

of guests.Our Advantages and quick delivery, Competitive price ,high quality and long term

service to out customers.

Welcome to contact us if need any more information.

Contact

Supplier