Quality Assurance

Customized

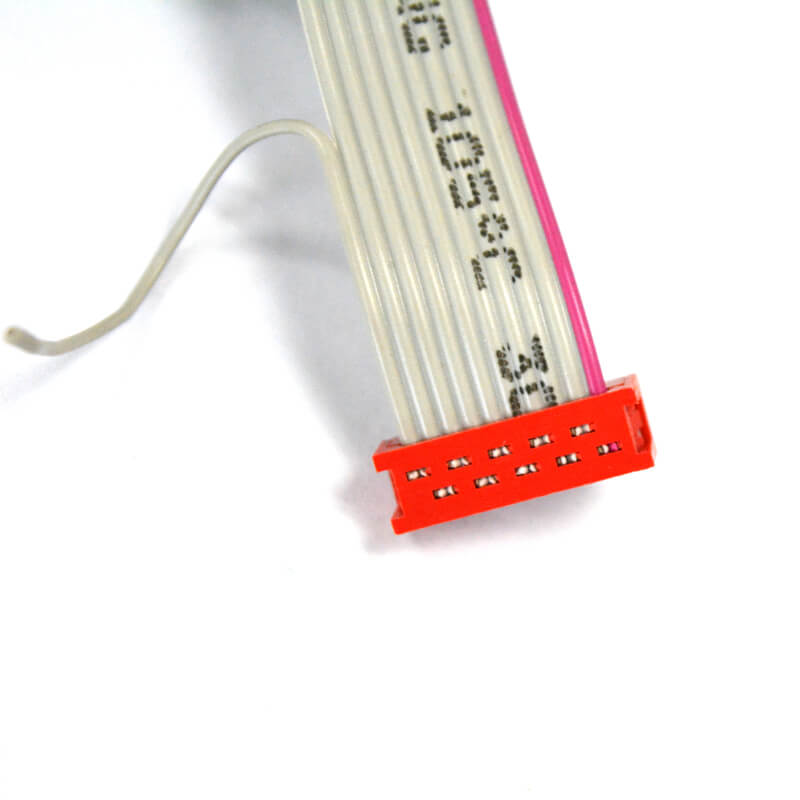

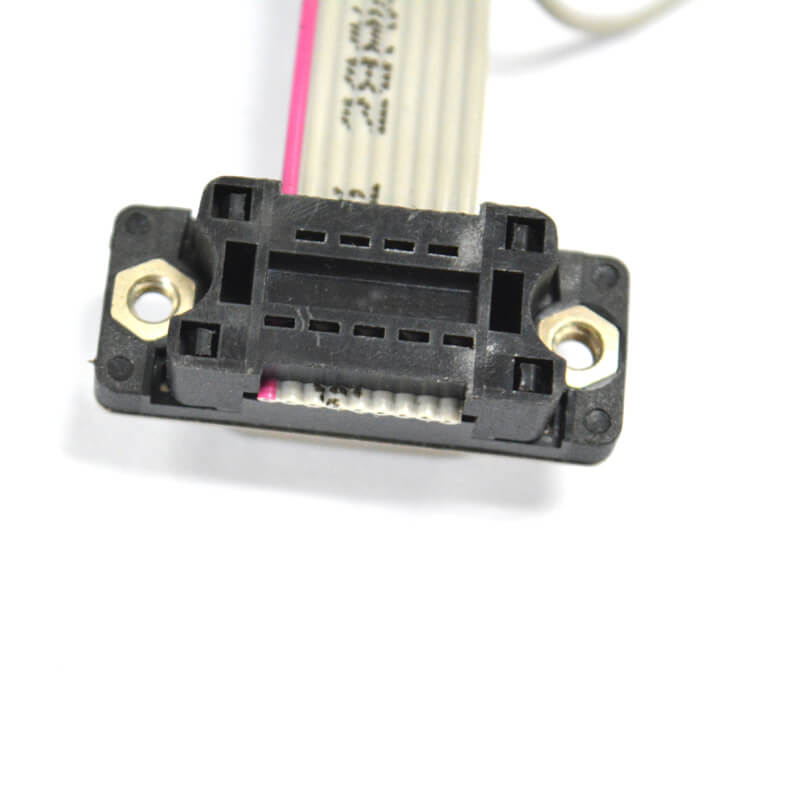

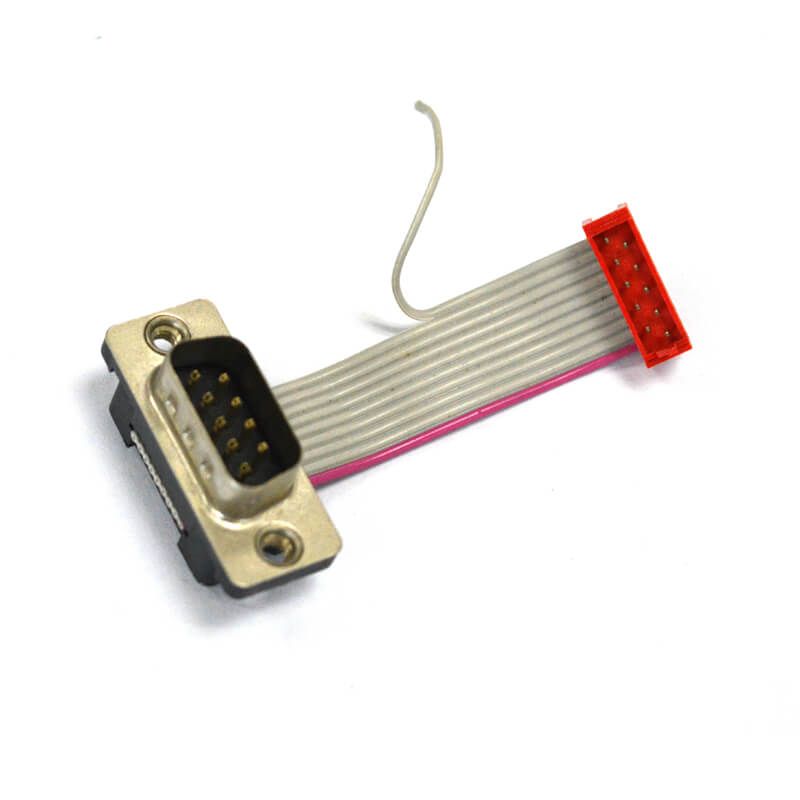

In-kind shooting

【Used For】Display screen

【Connector Type】DB-9P male, 2.54mm*10 pin box header

【Cable Type】UL2651#28AWG/10P

【Material】PVC, tinned copper

【Production Process】Cutting wire, crimping, electrical logging, inspection, packing, ship out

【Color】Grey with red edge

【Length】10CM/20CM/50CM/ customized

Cutting Wire

1.wire gauge and size must be compliant to drawing.

2.Working table must be clean and no foreign material.

3.No color difference, no dirty or damage on the jacket.

4.No color difference in same lot cable.

5.Conductor must be in the middle of wire, insulation must be uniform.

Contact

Supplier