Product Information

Price Terms

fob, cif

Minimum Order

one piece

Payment Terms

t/t, others

Product Information

Price Terms

fob, cif

Minimum Order

one piece

Payment Terms

t/t, others

Product Detail

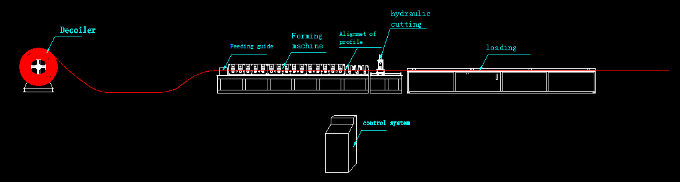

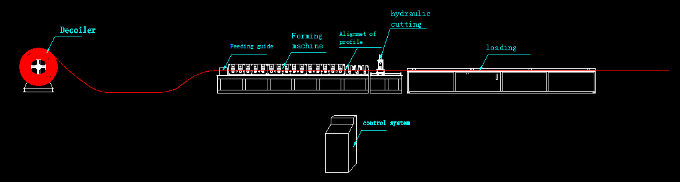

1. The Chart of Door Making Machine Process Flow:

Manual decoiler—Feeding guide—door press machine —Alignment —Hydraulic Control System—Automatic cutting machine—output tableManual

2. Door Manufacturing Machines Equipment Detailed Parameters:

3. specification of component

4.Machine Door In Details

Manual decoiler—Feeding guide—door press machine —Alignment —Hydraulic Control System—Automatic cutting machine—output tableManual

2. Door Manufacturing Machines Equipment Detailed Parameters:

| NO. |

|

|

| 1 | Door Frame Making Machine Suitable Material |

201/304 stainless |

| 2 | door cnc machine roll stands | 18 stands |

| 3 |

Thickness |

1.2mm |

| 4 | Appearance size | About 6500*900*900mm |

| 5 | Total power | Main power: 5.5kw Cutting power: 2.2kw |

| 6 | Reduction box | 3#cycloidal pin wheel speed reducer |

| 8 | speed | 0-25m/min |

| 9 | Diameter of shaft | ¢48mm |

| 10 | Voltage | 380V50Hz |

3. specification of component

| NO. | Specification |

Manual Decoiler

|

Usage: It is used to support the steel coil is uncoiled by hand

|

Punching mould |

①Punching mould:It’s adopts guide post Structure Punching shot and under templates are adopts Cr12MOV steel, all process vacuum oven quench, hardness reach HRC 60-62°,and the life will be longer 2-3times than general mould, is not easy to loss |

Feeding guide

|

|

Rack

|

|

| Wall Structure | ①Thickness is 25mm,it is adopts surface precision grinding ,wire-eletrode cutting and blackening |

door rolling machine

|

|

Hydraulic system

|

|

touch screen

|

|

| Shearing Mechanism |

|

Out table

|

It adopts welded steel and supported roller to transmit the products which used to collect the finish product |

Contact

Supplier

Contact us

Tell us your Buying Requirements