Drawing Die For Sheet Metal Component-HG

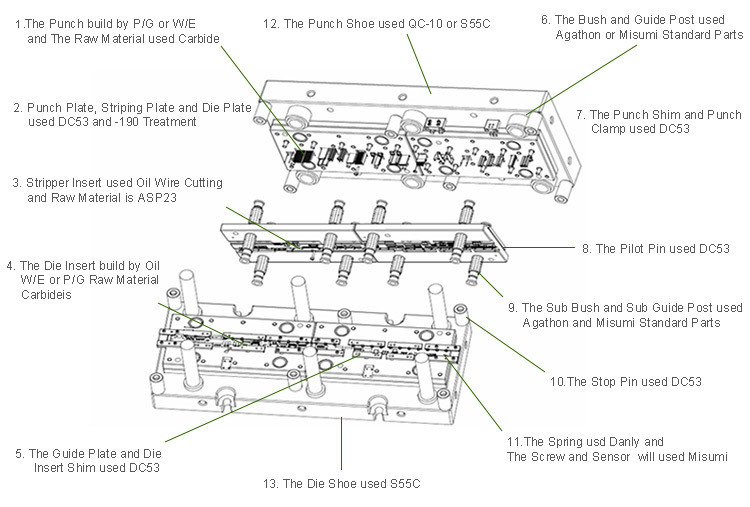

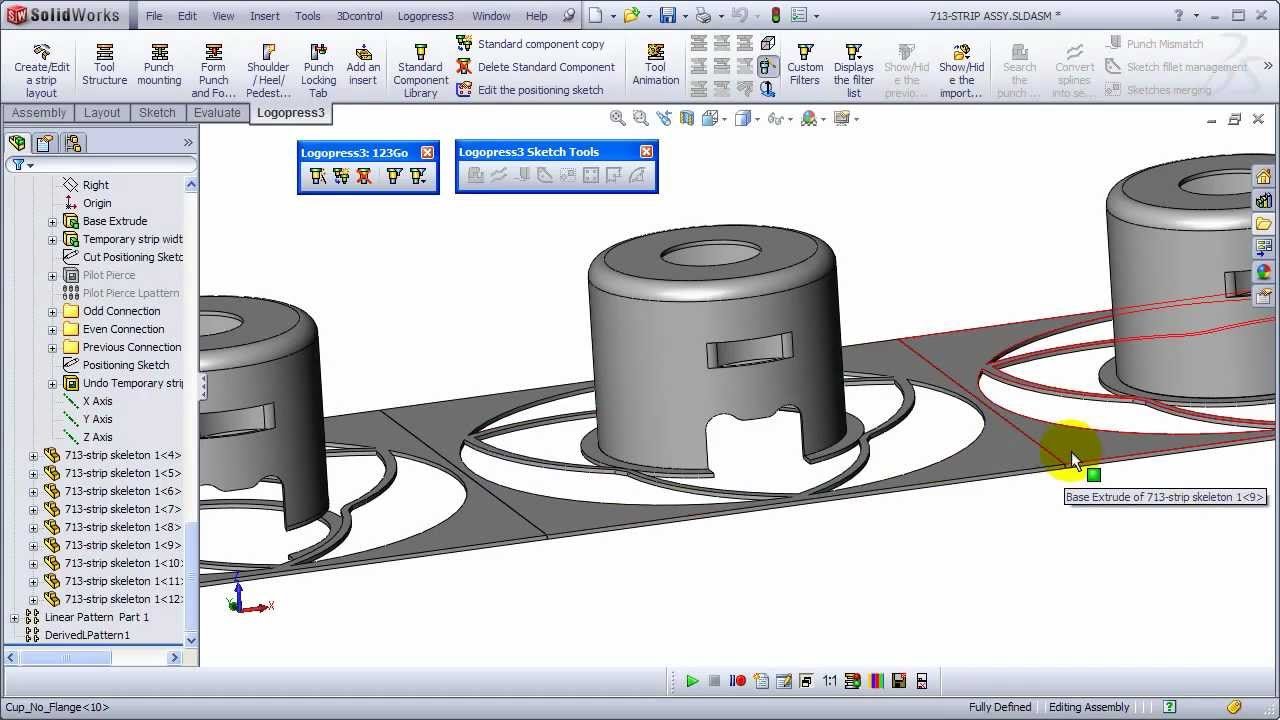

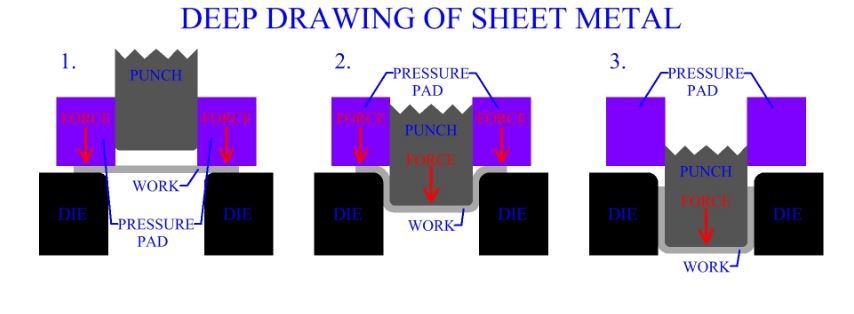

Deep drawing of sheet metal is performed with a punch and die. The punch is the desired shape of the base of the part, once drawn. The die cavity matches the punch and is a little wider to allow for its passage, as well as clearance. This setup is similar to sheet metal cutting operations. As in cutting, clearance is the lateral distance between the die edge and the punch edge. The sheet metal work piece, called a blank, is placed over the die opening. A blankholder, that surrounds the punch, applies pressure to the entire surface of the blank, (except the area under the punch), holding the sheet metal work flat against the die. The punch travels towards the blank. After contacting the work, the punch forces the sheet metal into the die cavity, forming its shape.

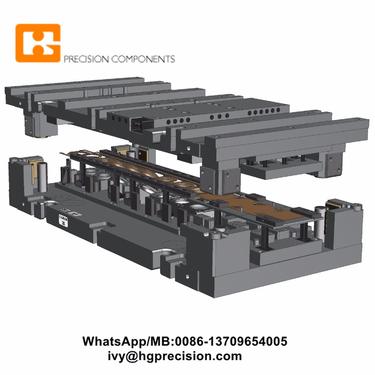

Equipment for sheet metal deep drawing processes would involve a double action, one for the blank holder and one for the punch. Both mechanical and hydraulic presses are used in manufacturing industry. Typically the hydraulic press can control the blankholder and punch actions separately, but the mechanical press is faster. Punch and die materials, for the deep drawing of sheet metal, are usually tool steels and iron. However, the range of materials for punch and die can span from plastics to carbides. Parts are usually drawn at speeds of 4 to 12 inches per second.

Contact

Supplier