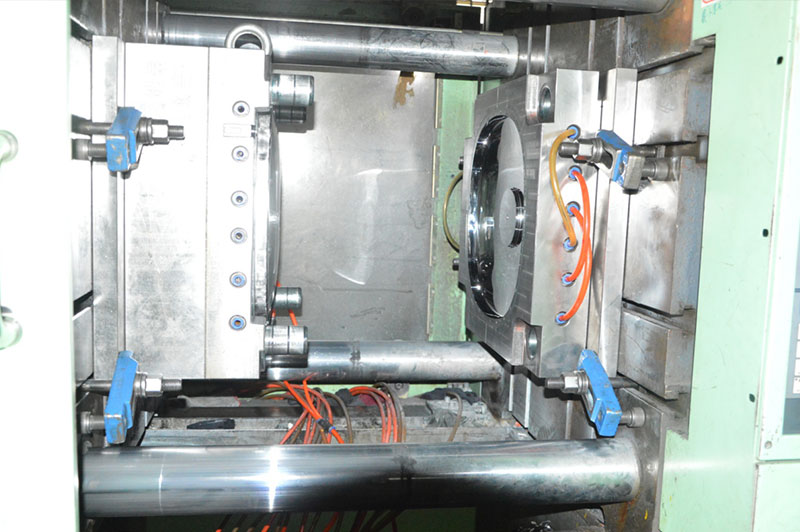

The mold adopts the slider structure on both sides, and the red color in the middle is the color of the matching mold, which verifies the processing error and makes the product form flawless.

Electric cooker mold manufacturing

Product Name:

electric cooker

Mold number:

zg16133

Material thickness:

2.2mm

Product material:

abs plastic

Product size:

200*140*80

Mold weight:

980 kg

Mold size:

550*450*510

Applicable injection molding machine tonnage:

400t

First trial mold cycle:

42 days

Product Name:

electric cooker

Mold number:

zg16133

Material thickness:

2.2mm

Supplier Info.

Company Name: Foshan Nanhai Zhuangao Mold Co., Ltd

Registration Date:

2007

Country / Region:

guangdong / China

City:

foshan

Main Products:

plastic injection molding,plastic mould,chinamouldmanufacturer

Product Detail

RICE COOKER MOLD

Rice cooker is a common daily necessities for people. Life is improving day by day. People's demand for product quality is also increasing day by day. Therefore, people's demand for product production is also getting higher and higher. Our company has rich manufacturing experience in household electrical appliances moulds. We have strict control over the quality audit of moulds, including the three-dimensional inspection of moulds, so as to minimize the processing error. Within the scope, strive to achieve the best quality and details of products.

The mold adopts the slider structure on both sides, and the red color in the middle is the color of the matching mold, which verifies the processing error and makes the product form flawless.

This is EDM processing. Our company has its own EDM department, can ensure the progress of die processing, and error control, improve the efficiency of die processing.

RICE COOKER MOLD

This is our test Mould of Injection Molding Machine,which can satisfy the trial production of the products. According to the trial production products, we can continuously improve the mould, so as to produce the quality of the flawless mould, and give the best products to the customers.

FACTORY DISPLAY

ZHUANGAO

The company has been committed to improving the precision of machining process. Under the guidance of the strong R&D department, the company has developed strictly technical solutions and inspection standards for various processing links, and actively introduced advanced management software. At present, all the quality and progress parts of the company are under the close supervision of management software, the company can always maintain high quality molds while operating efficiently.

CERTIFICATE DISPLAY

ZHUANGAO

The company has fully implemented the modern production model and management system in management and has passed ISO9001 :2008 / ISO14001 :2004 / TS 16949 international system certification.

SIX CORE ADVANTAGES

ZHUANGAO

CUSTOMIZATION SERVICE

ZHUANGAO

1

1

Sign the mold contract

1

1

Product Drawings Review

1

1

Mold drawing design

1

1

Precision manufacturing and processing

1

1

Size monitoring

1

1

Mold assembly

1

1

Die trial production

1

1

Die acceptance

1

1

Mold mass production

1

1

After-Sales service

Contact

Supplier

Contact us

Tell us your Buying Requirements

You Might Also Like

Tungsten Steel 2 Flutes N45YPX2107 N45YPX2108 Nigel China Manual Milling Cutter End Milling Cutter Ballnose Milling Cutter

Precision CNC machining parts aluminum parts for telecom housings with silver plating

CNC machined aluminum parts CNC casting parts for optics camera housing

CNC machined part precision cnc machining aluminum part