Electrical Cabinet Frame Roll Forming Machine

Product Descriptions

Automaitc electric factory using cabinet frame roll forming machine with welding for electric cabinet rack, electronic box pole, metal case frame which using in switchgear system, low voltage panel building, control cabinetelectrical instruments etc.

Version to design

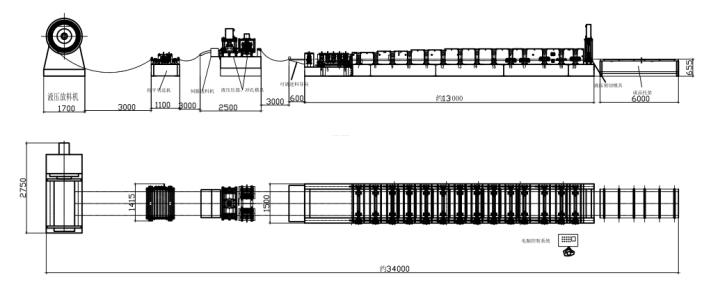

Working Flow

Uncoiler -- Servo Feeding -- Punching -- roll forming machine -- Roller welding -- Saw cutting -- finished product output table

Product Parameters

Items | Specifications |

Suitable material | PPGI/Aluminium sheet/galvanized sheet/various sheet plates |

Thickness of coil sheet | 0.8-1mm |

Coil width | 825mm |

Effective width | 500mm |

Material of main frame | 350H steel |

Diameter of shaft | 70mm, high grade 45# steel |

Roller | High grade 45# steel, quenched and tempered treatment hard chrome plated 0.05-0.07mm |

Thickness of middle plate | 16mm, 45# steel plate |

Forming station | 18 rows |

Drive type | By chain(1.0 inch), link bearing model 6210 |

Sidewall connection bar | 25mm, zinc plated |

Forming speed | About 10-15m/min |

Control System | PLC |

Material of razor blades | Cr 12, quenching 58-62℃ |

Main Components

5 ton decoiler | 1 set |

Main roll forming machine | 1 set |

Cutting device | 2 sets |

PLC Control box | 1 unit |

Hydraulic station | 1 unit |

Out table | 2 units |

Safety cover | 1 unit(Optional) |

Application Pictures

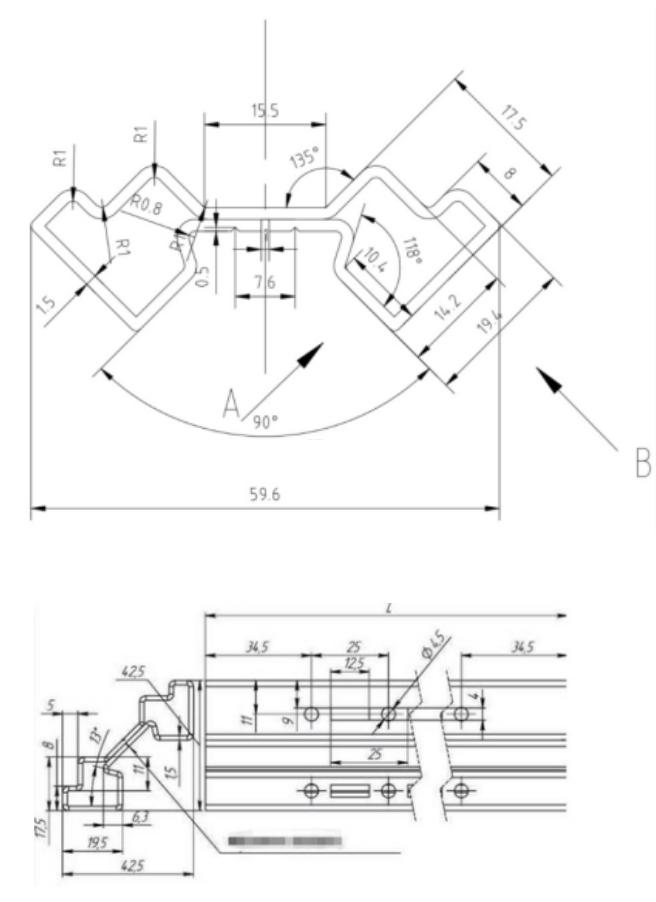

Electrical cabinet frame. It is a column. The beam is provided with at least one sealing groove. The angular connector is designed in a three-dimensional coordinate shape. The groove is matched with the column and the sealing groove on the beam. The advantages are increased structural strength and improved cabinet protection. , Thereby improving the replacement of electrical products and the safety of operators.

Contact

Supplier

Agriculture Machinery & Equipment

Apparel & Textile Machinery

Chemical Machinery & Equipment

Energy & Mineral Equipment

Engineering & Construction Machinery

Food & Beverage Machinery

Home Product Making Machinery

Industry Laser Equipment

Machine Tool Equipment

Metal & Metallurgy Machinery

Other Machinery & Industry Equipment

Packaging Machine

Paper Production Machinery

Plastic & Rubber Machinery

Printing Machine

Refrigeration & Heat Exchange Equipment

Woodworking Machinery

Environmental Machinery

Machinery Accessories

Material Handling Equipment

Welding Equipment

Cleaning Equipments

Commercial Machinery

Air-Compressors & Parts