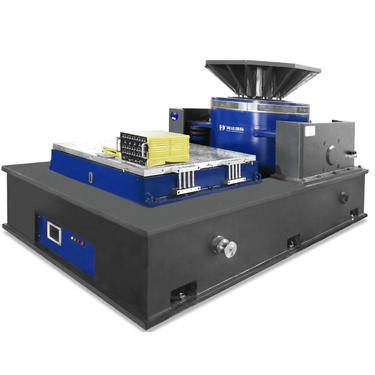

Electro-dynamic Vibration Testing System

Technical Solution of Electro-dynamic Vibration Testing System

Electro-dynamic vibration table testing system is widely used in defense, aviation, aerospace, communications, electronics, automobiles, home appliances, and other industries. This type of equipment is used for discovering the early faults, simulating the actual working condition and the structure strength test, the product application is wide, the application width is obvious, the test effect is remarkable and reliable. Sine wave, FM, sweep, programmable, frequency multiplier, logarithm, maximum acceleration, amplitude modulation, time control, full function computer control, simple fixed acceleration/fixed amplitude. Equipment through continuous failure to run 3 months of testing, stable performance, reliable quality.

FEATURES

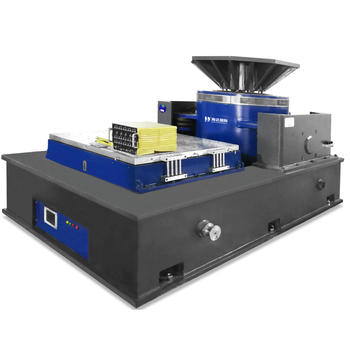

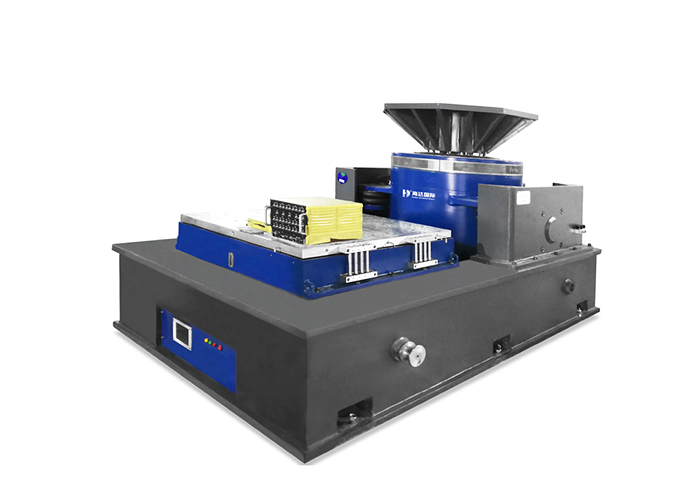

Block Diagram Shaker Body with Slip Table Power Amplifier and Blower

PERFORMANCE DATA SHEET

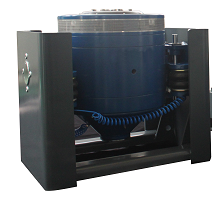

Shaker | ||

Sine force (peak) | 30kN | |

Shock force (peak) | 60 kN | |

Frequency range | 5~2,600 Hz | |

Displacement (continuous) | 100 mm | |

Max. Velocity | 1.8 m/s | |

Max. Acceleration | 75 G | |

Armature Diameter | 445 mm | |

1st order resonant frequency | 2,400 Hz | |

Allowable eccentric moment | >500 Nxm | |

Armature weight | 40 kg | |

HE/ST screw dimension | M10 (metric) | |

Axial vibration isolation frequency | <3 Hz | |

Max. Payload | 500 kg | |

Magnetic flux leakage | ≤1 mT | |

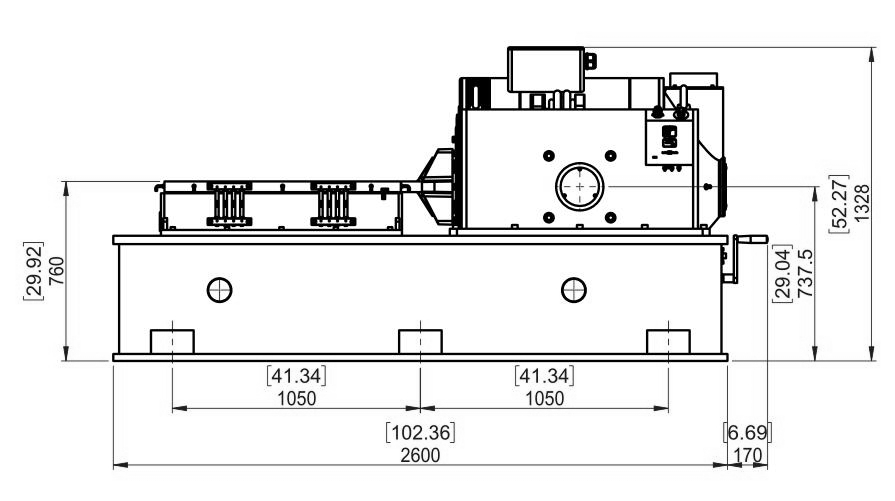

Dimensions (L×W×H, unpacked) | 1,330x860x1,250 mm | |

Weight (unpacked) | 2,500 kg | |

Installation | Rubber mat (anchor bolts required) | |

Power Amplifier | ||

Amplifier output | 30 kVA | |

SNR | >65 dB | |

Rated output voltage | 120 Vrms | |

Amplifier efficiency | > 90% | |

Dimensions (L×W×H, unpacked) | 800x900x2,100 mm | |

Weight (unpacked) | 500 kg | |

Blower | ||

Air volume | 0.46 m3/s | |

Power | 7.5 kW | |

Air duct diameter | 200 mm | |

Air pressure | 8.8kPa | |

Installation | Able to connect to ceiling (up to two 90 degree bends), max 20’ run | |

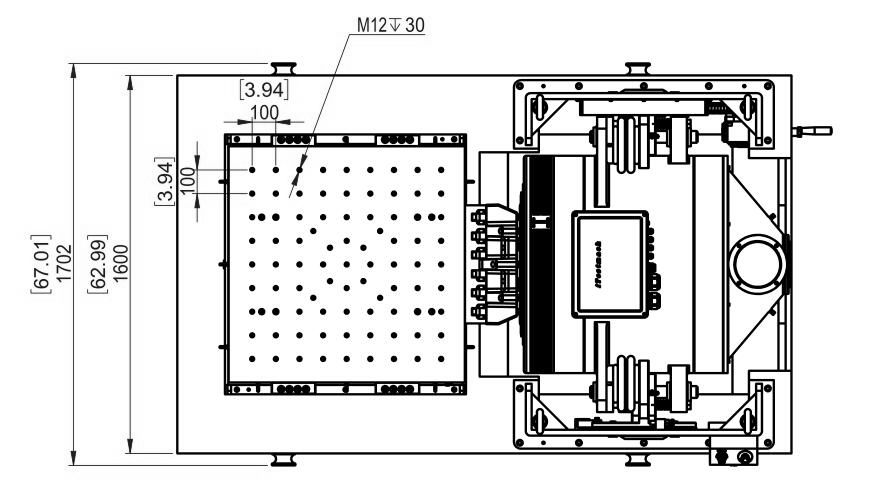

Horizontal Slip Table | ||

Dimensions | 600x600 mm | |

Thickness | 45 mm | |

Frequency limit | 2,000 Hz | |

Effective mass | 54 kg | |

Note: 1. High pressure oil-film bearing is used for better uniformity. | ||

Vibration Controller and Accelerometer | ||

Vibration Controller VT-9008-4 | 4 Channel Vibration Controller with Sine and Self Calibration. | |

100mV/g, Range: 50g, Working Freq.: 1-10kHz, Weight: 11gram, with 10ft low noise cable | ||

Other supported functions/accessories | ||

Environmental chambers | Supported | |

Mobile devices | Customizable | |

Insulation boards | Customizable | |

Fixture | Customizable | |

Working environment of the system | ||

Temperature range | 0-40℃ | |

Humidity range | 0~90% , no condensation | |

Power requirements | 380V/3ph/50Hz, 40kVA | |

Compressed air pressure | 0.6 Mpa | |

Dimensions for reference only

Characteristics: Ultra mute work; The machine base uses the high quality material, installs conveniently, the operation is smooth, does not need to install the The, the control circuit digitization control and the display frequency, the PID adjusts the function, causes the equipment work to be more stable, reliable, sweeps the frequency and the fixed frequency operation way, adapts to the different profession test request To solve the interference of the strong electromagnetic field to the control circuit, and to increase the working time set, so that the test product reaches the accurate test time.

How to use

1. the control manual to complete the procedure

2. such as Operation error so that can not work, you can use the recovery method of the steps of the input, and then set a single group or other running steps.

3. before use to press the external start switch, appears COO namely lets go, opens the key.

4. Taiwan Body:

1) The table body foot sleeve as far as possible fixed

2) power supply on/work in the output line can not be unplugged

3) Place the level as far as possible

4) components can be changed, the line should not be changed or from the connection.

5) The Taiwan body must not be all or part of the reorganization, only according to specifications for a single component and with the original confirmation password.

5. the amplitude inside the code

1) Do not adjust too large before or after the boot

2) low-key amplitude of high amplitude modulation

3) Control Panel Amplitude Knob placed in the middle position test items: placed to focus on the main point, reduce the left flat right.

4) control Box: Can not be placed on the top or underground operation

6. Inside Code:

1) reset when running or operating incorrectly

2) Control The Reset method step, each inside code only set one time to save can

3) usually must use the internal code can not be set randomly

7. Control Box:

1) The connecting line of the body must be locked tightly after hanging

2) the vibration direction switch and the output connection line are correspondence, can not connect the wrong

8. testing: Non-special test should use full wave test

9. the Taiwan body: can not produce the collision sound, the upper and lower center axis mutual touch will cause the spring steel piece rupture to be immediately shut down, amplitude modulation is adjusted small then turns on.

10. other unknown:

Do not arbitrarily change internal components and lines

11. the reason is bad:

1) The use of computer models can not be used for shaking table control

2) can not reload the driver

12. for the Ista-ia test, the operator to protect the sample, to prevent the test pieces slide out of the table;

13. gear gearbox replacement regularly;

14. Cut off all power when not working, keep clean; 5, non-staff can not operate at will;

Contact

Supplier