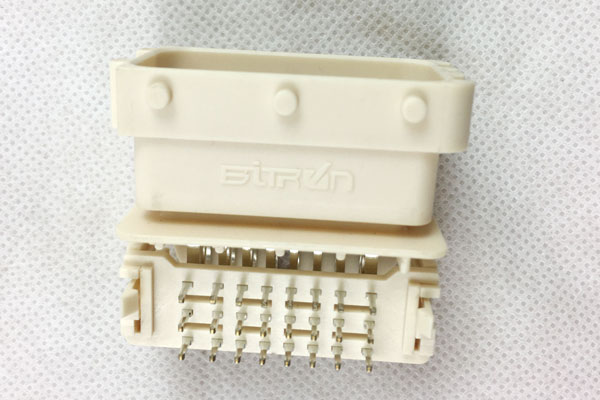

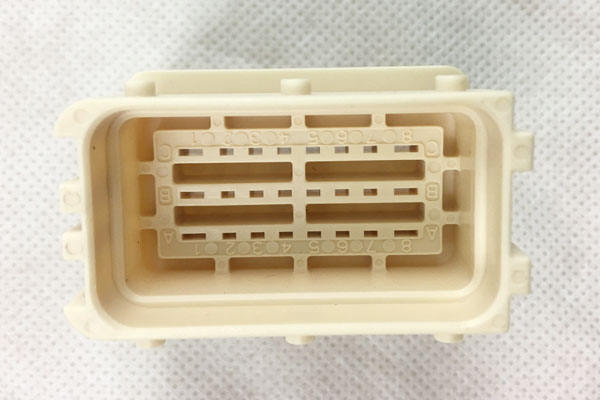

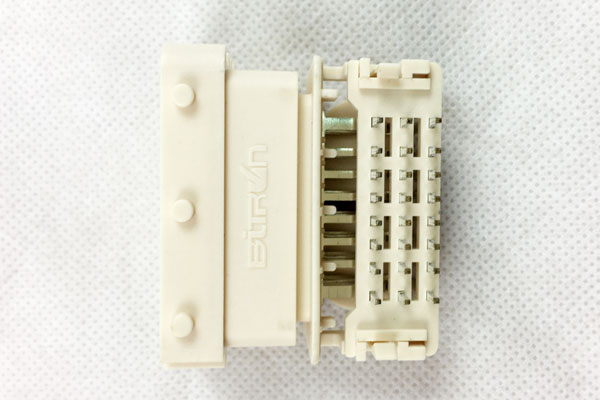

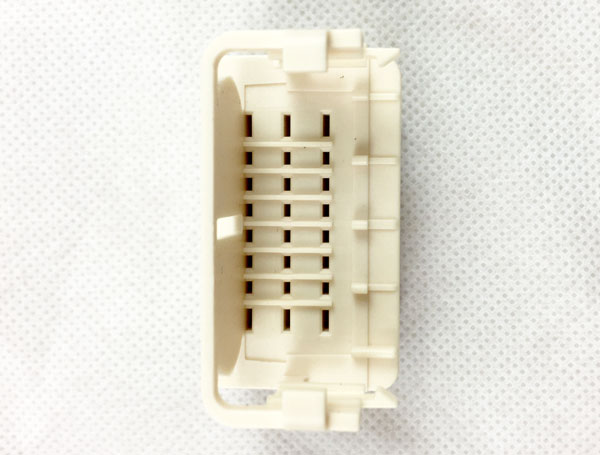

Electronic connector product by precision injection molding

| Part Name: | Electronic connector |

| Part size: | 45*39.5*21mm |

| Raw Material: | PA9T30GF |

| Color: | RAL9005,Black |

| Mould Cavity No.: | 1*4 |

| Injection gate: | Hot runner |

| Surface finished: | VDI3400-33 |

| Core &Cavity steel: | 1.2344,hardness 48~52HRC |

| Mold component standard: | HASCO or equivalent |

| Injection machine size: | 250T |

| Cycle time: | 40S |

| Mold life: | 100000 shots |

| Customer: | Bitron |

| Export: | Italy |

This connector include two different parts(upper and lower halves),were to be produced in a single mold.Prior to the start of production,the question arose as to whether a second gate might not be required to fill the part.To avoid weld lines and entrapped air.however,it might also be necessary to use only a single gate.This flexibility as to gating was supposed to be possible simple by switching a hot runner nozzle on or off.A further difficulty resulted from the small amount of space in which the gates were to be located on the face of the molded part.All of these requirements were satisfied through the particular arrangement of the conductive,internally heated hot-runner system.

Mold design-We made this mold with four cavity.Runner system consists of a heated sprue bushing,a hot-runner manifold and four hot-runner nozzles.The hot-runner nozzles have not been installed parallel to the longitudinal axis of the mold,but rather at an angle.In spite of the unfavorable geometric relationships,it is possible to gate each part on its face in this manner.This arrangement is possible,because the solidified melt in the outer regions of the hot-runner manifold and nozzle channels precludes any possibility of leakage.Each of the hot-runner nozzle is individually controlled and can thus be switched on or off as required.It is thus possible to fill the part through either on or two gates.These measures alone,however,would not have been adequate to vary the gating possibilities.Attention also have to be given to the hot-runner manifold to ensure that no melt stagnated at continuously high temperatures in the runner channels when the various gating possibility were being employed.

Contact

Supplier