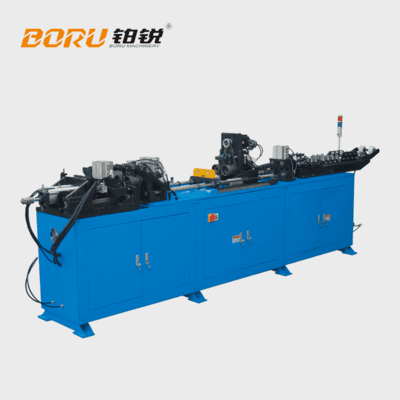

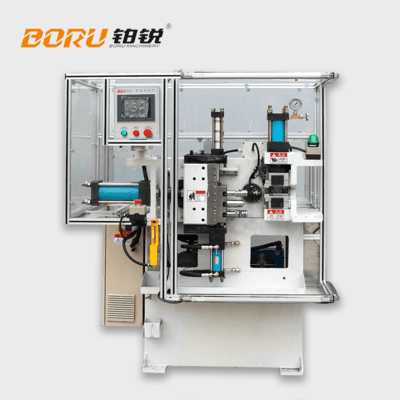

End forming & circle groove machine

Model:

-

Minimum:

-

Payment:

-

Origin:

-

Brand:

boru

Model:

-

Minimum:

-

Payment:

-

Product Detail

▶ Equipment profile

This machine is the end forming, automatic production equipment one of the spiral groove, the equipment by the automatic feeding mechanism, four station end forming mechanism, spiral groove mechanism and feeding mechanism composed of; work equipment, feeding manipulator clamping the clamping mechanism will work on pinch to the next the process mechanism, the mechanism is processed at the same time, finished evacuation manipulator the workpiece to the next step of processing, the equipment can realize the pipe into hopper after each process and processing, can save manpower, improve production efficiency, is the ideal equipment for pipe pipe molding.

▶ Technical specifications and parameters

| Device name | Automatic end forming machine |

| Minimum machining diameter | φ8×1mm |

| Maximum diameter of machined tube * wall thickness | φ20×1.5mm |

| Length of processing pipe | 150-1000mm |

| Processing time | 12-20S |

| The thrust of the end part of the jig | 7000kg (Ф80 Cylinder) |

| The thrust of the end punch | 7500kg (Ф100 Adjustable cylinder) |

| End clamp travel | 50㎜ |

| End punch stroke | 100㎜ |

| Electronic control mode | PLC |

| Operation mode | Automatic and manual inching |

| Feeding method | Automatic feeding |

| End section maximum coaxiality error | ±0.05㎜ |

| Maximum machining depth error at end part | ±0.5㎜ |

| Spinning accuracy of rotary groove parts | ≦±0.05mm |

| Groove part processing method | Servo groove |

| Oil pump motor | 5.5KW |

| Oil pump pressure | 10MPA |

| Overall dimensions of equipment (L * w * h) | 3200*2400*1800 |

| Other | Automatic upper pressing device for equipment |

Contact

Supplier

Contact us

Tell us your Buying Requirements